Control method for calculating exhaust temperature of compressor of air conditioner

A compressor exhaust and control method technology, which is applied in heating and ventilation control systems, heating methods, space heating and ventilation, etc. Can run normally and other issues, to achieve the effect of wide application range, low production cost and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

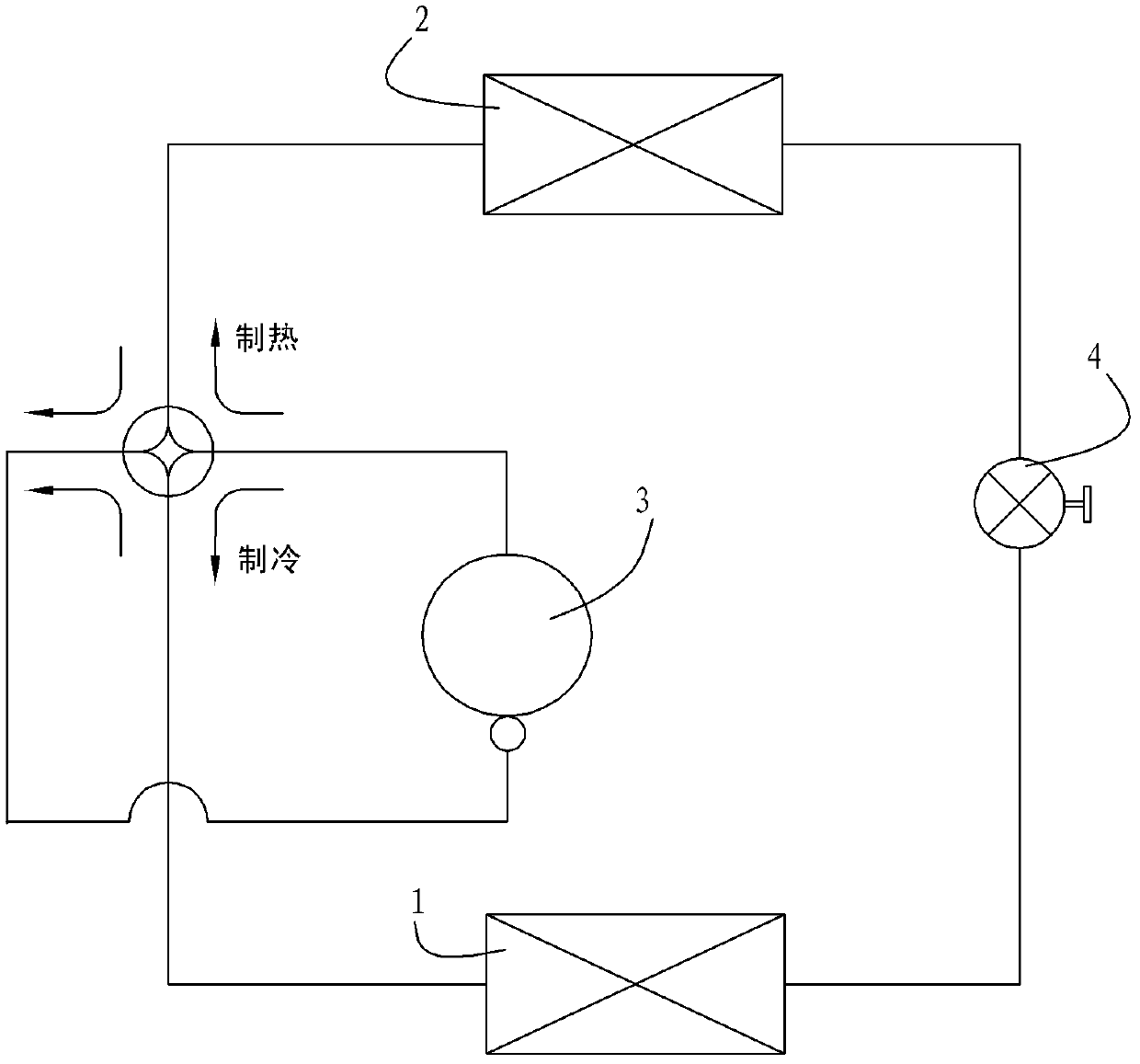

[0057] see Figure 1-Figure 2 , The outdoor system of the inverter air conditioner still installs a compressor discharge temperature sensor on the discharge pipe of the compressor 3 to sample the discharge temperature of the compressor 3. Inverter air conditioner such as figure 2 As shown, temperature sensors are respectively installed on the outdoor heat exchanger 1 and the indoor heat exchanger 2, and the temperature Tc of the indoor heat exchanger and the temperature Te of the outdoor heat exchanger are detected by the sensors.

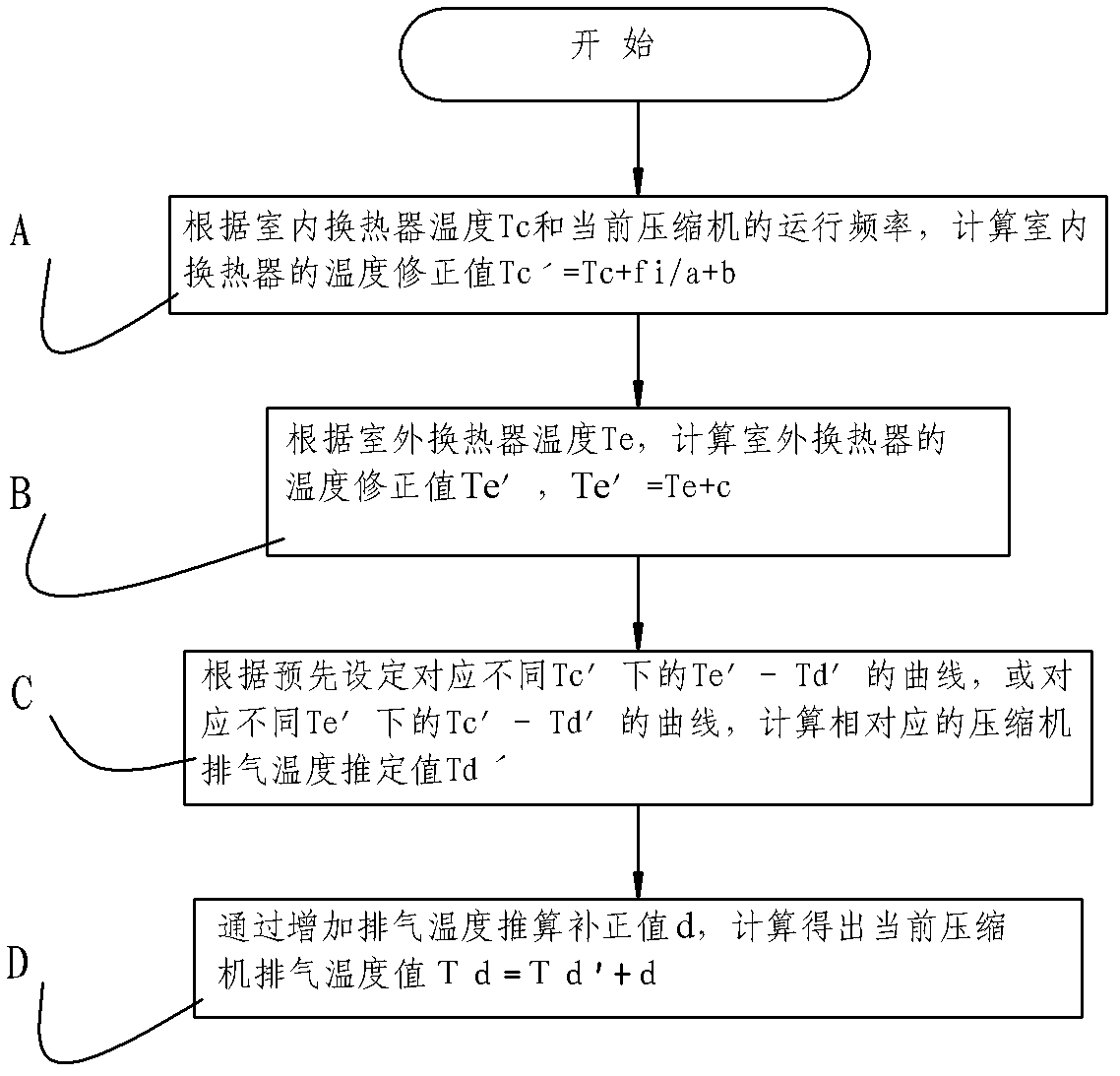

[0058] When the air conditioning system judges that the compressor discharge temperature sensor is faulty, if figure 1 As shown, follow the steps below to calculate the compressor discharge temperature based on the temperature Te of the outdoor heat exchanger and the temperature Tc of the indoor heat exchanger:

[0059] Step A, calculate the temperature correction value Tc' of the indoor heat exchanger 2 according to the detected temperature Tc ...

Embodiment 2

[0097] The difference between this embodiment and the control method of the air conditioner in Embodiment 1 is that, as Figure 5 As shown in the flow chart, since the inverter air conditioner in this embodiment can run at high frequency, step D1 is added to correct the high frequency operation of the compressor. Frequency operation correction Td=Td'+d+k×(fi-fb); fi is the current operating frequency of the compressor, fb is the reference value of the high-frequency frequency of the compressor, and the value range of fb is 70Hz~ 150Hz, k is the high-frequency operation correction coefficient of the compressor, and the value range of k is 0.05~0.3.

[0098] Judgment: When the current operating frequency fi of the compressor is greater than fb, the high-frequency operation correction of the compressor is performed; otherwise, the high-frequency operation correction of the compressor is not performed; the other calculation detailed control methods are similar to those in Embodime...

Embodiment 3

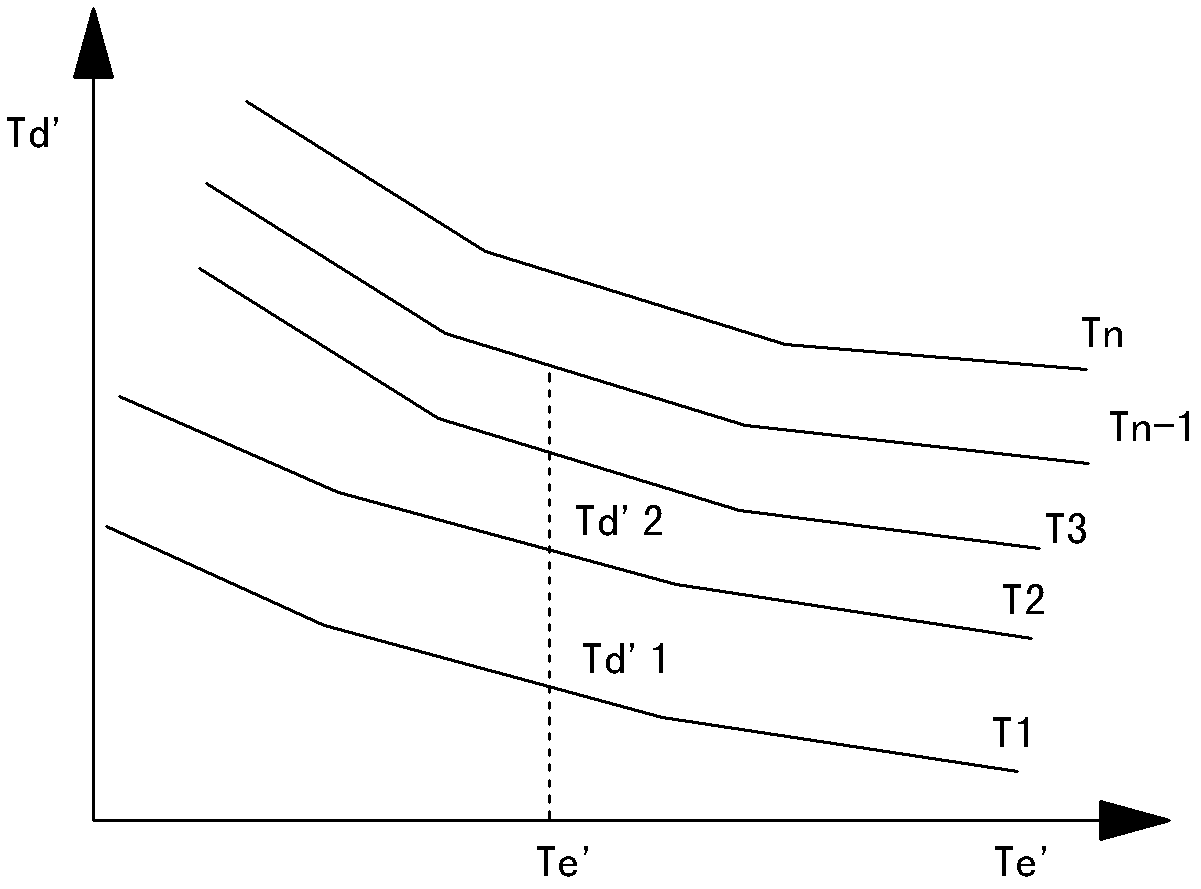

[0101] The air conditioner of this embodiment is different from the air conditioners of the above embodiments in that it adopts a control method of estimating the discharge temperature of the compressor according to the temperature of the evaporator and the temperature of the outdoor heat exchanger, and compares the calculated discharge temperature of the compressor with Compare the temperature values sampled by the discharge temperature sensor. When the difference between the two temperature values is relatively large, it is judged that the compressor discharge temperature sensor has fallen off or failed. The steps and implementation of the control method for estimating the compressor discharge temperature used in this embodiment Example 1 is similar, except that the calculation method in step C uses a preset curve corresponding to Tc'-Td' under different Te' to calculate the corresponding estimated value Td' of the compressor discharge temperature; as Image 6 As shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com