Stress monitoring and early warning method and system for prestress ring of cold extrusion mold

A prestressing ring and stress monitoring technology, which is applied in the field of metal plastic processing, can solve problems such as mold and prestressing ring cracking, mold and prestressing ring stress damage, etc., and achieve the effects of convenient operation, improved safety, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific implementation plan

[0023] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following describes the device of the present invention in detail with reference to the accompanying drawings and embodiments:

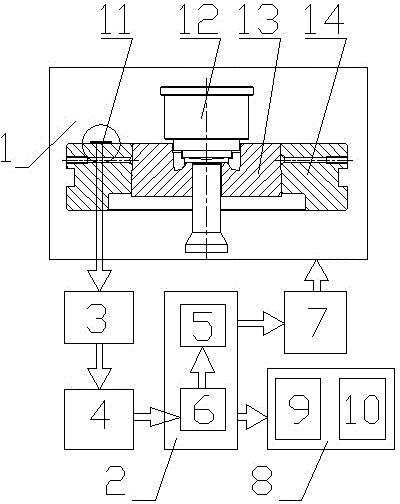

[0024] A cold extrusion die stress monitoring and early warning system consists of six parts: strain gauges, bridge boxes 3, dynamic strain gauges 4, industrial computers 2, feedback control switches 7, and alarms 8.

[0025] The strain gauge adopts a resistance strain gauge 11, which is pasted on the surface of the prestressed ring 14 after surface treatment. The surface of the resistance strain gauge 11 is covered with a polyethylene film. The resistance strain gauge 11 is connected to the electric wire through a single bridge. The input terminal of the bridge box 3 is connected.

[0026] The bridge box 3 has an input terminal and an output terminal. The input terminal of the bridge box 3 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com