Spectrometer-component-based non-contact engine exhaust flame monitoring device

A non-contact monitoring device technology, applied in the field of optical detection, can solve the problems of increasing the probability of engine failure, affecting the timeliness and accuracy of engine failure, lack of intuitive perception of the overall working condition of the engine, etc., achieving high integration, The effect of job stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the drawings and embodiments.

[0022] In this embodiment, a non-contact engine plume flame monitoring device based on a spectrometer component is provided, and the device is used on a liquid rocket engine to monitor the health status of the liquid rocket engine without affecting the normal operation of the engine .

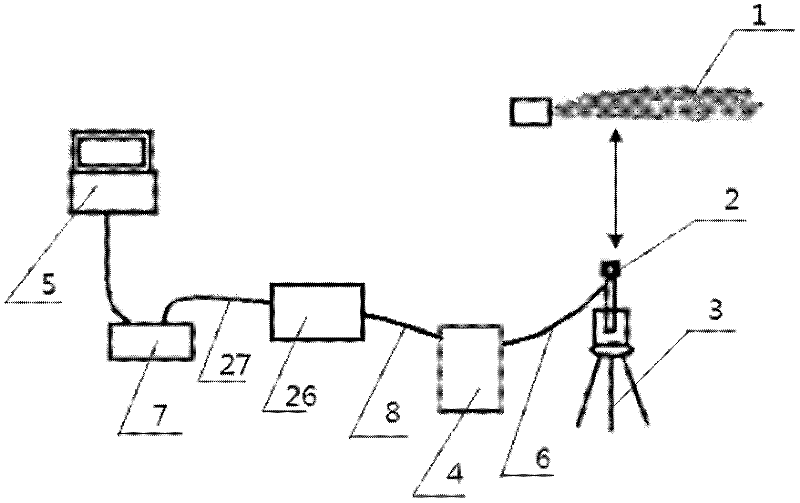

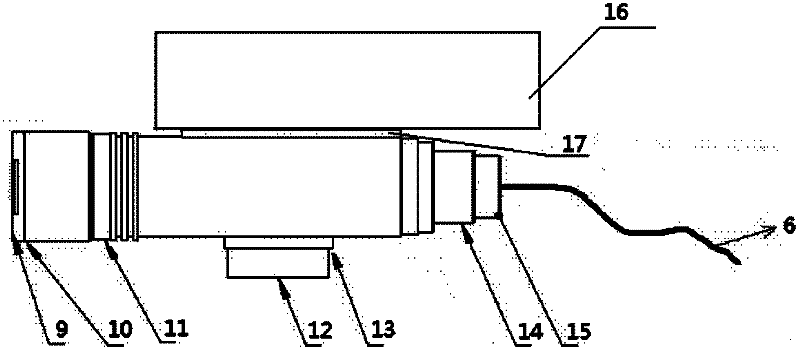

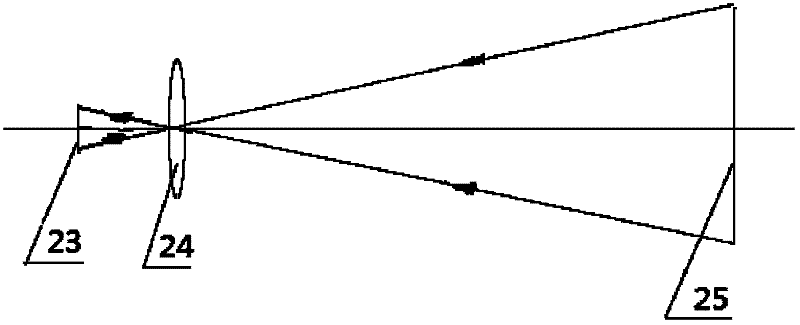

[0023] Such as figure 1 As shown, the device mainly includes a front optical system 2, a spectrometer assembly 4, a bracket 3, a computer 5, an optical fiber bundle 6, a USB data bus 8, a high-speed USB2 to network module 26, and a router 7. The connection relationship is: the front optical system 2 is installed on the bracket 3, the front optical system 2 and the spectrometer assembly 4 are connected through the optical fiber bundle 6, and the spectrometer assembly 4 is connected to the high-speed USB2 to network module 26 through the USB data bus 8. A network cable 27 is used to connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com