Modelica language-based simulation modeling method of amplitude-changing mechanism of automobile crane

A technology of truck cranes and luffing mechanisms, applied in simulators, instruments, control/regulation systems, etc., can solve problems such as model duplication, non-reusability, and complex data transmission, and achieve avoidance of hydraulic shock and vibration and overall machine stability Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

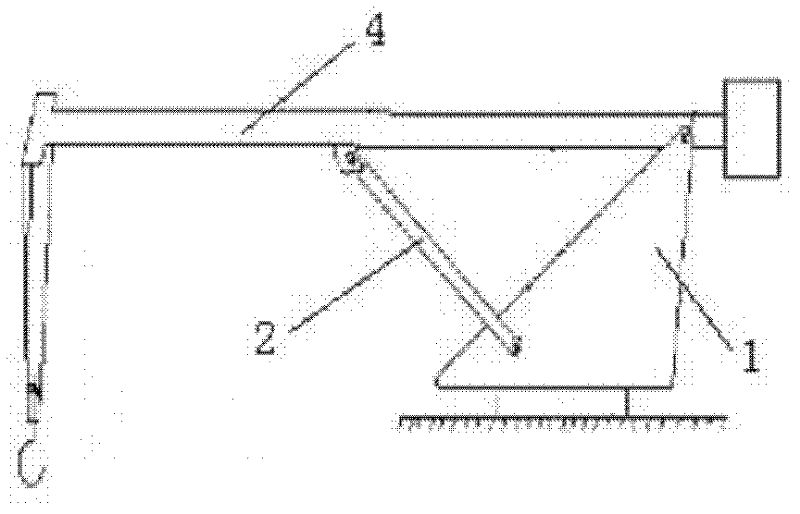

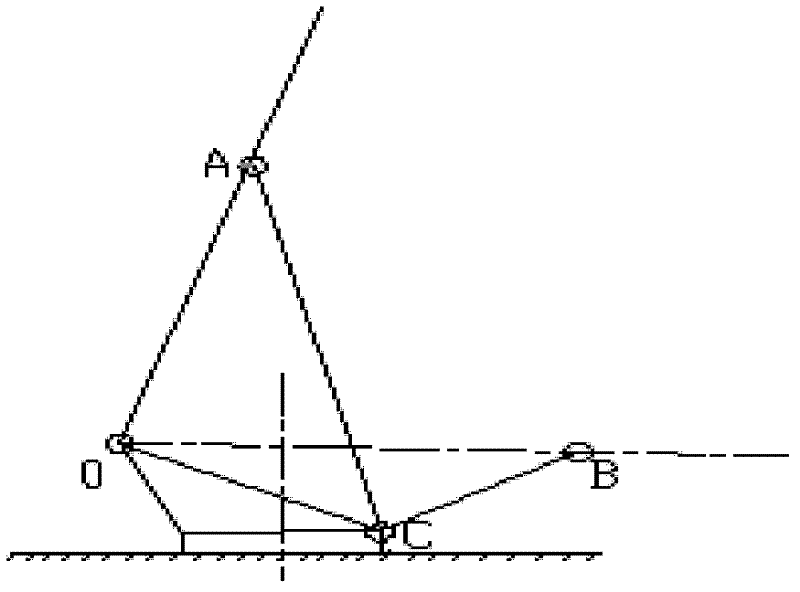

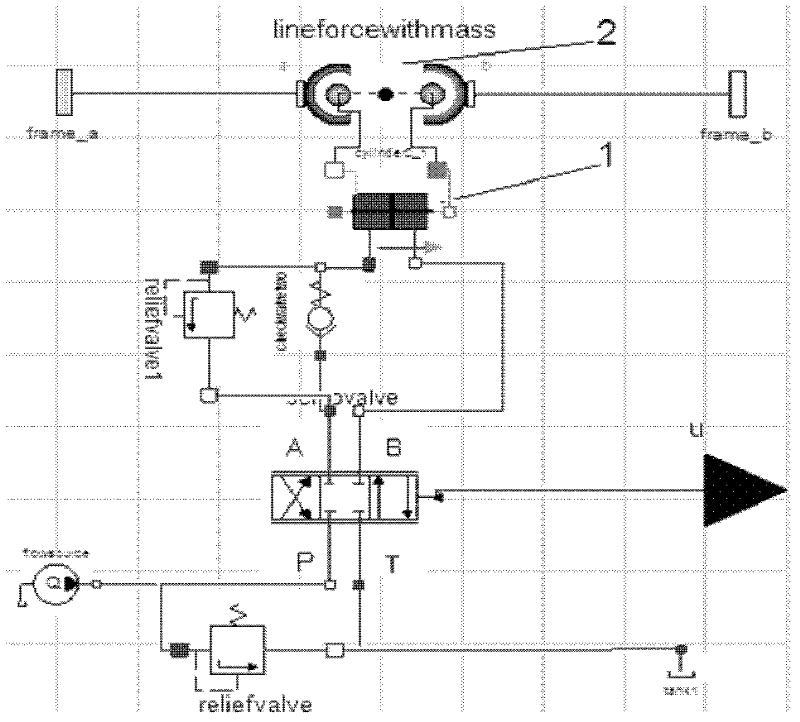

[0033] The simulation modeling steps of the truck crane luffing mechanism based on Modelica language in the present invention include: system dismantling, component level modeling, subsystem level modeling and system level modeling, namely including top-down system decomposition and bottom-down The above system builds. First, the designer disassembles the luffing mechanism of the real truck crane at the system level, builds a series of physical system models, including the mechanical system, hydraulic system and control system, and then decomposes the obtained subsystems to obtain components in different fields; Then, modeling analysis is carried out for the basic components obtained by decomposing, and the above basic components are used to build the various subsystems of the luffing mechanism, and then the completed subsystems are used to build a complete truc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com