Method for packaging dye sensitized solar cell by low glass powder

A solar cell and dye sensitization technology, which is applied in the field of dye sensitized solar cell technology, can solve the problems of increasing production cost, easy aging, and affecting production efficiency, and achieve the effects of reducing production cost, simplifying the production process, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

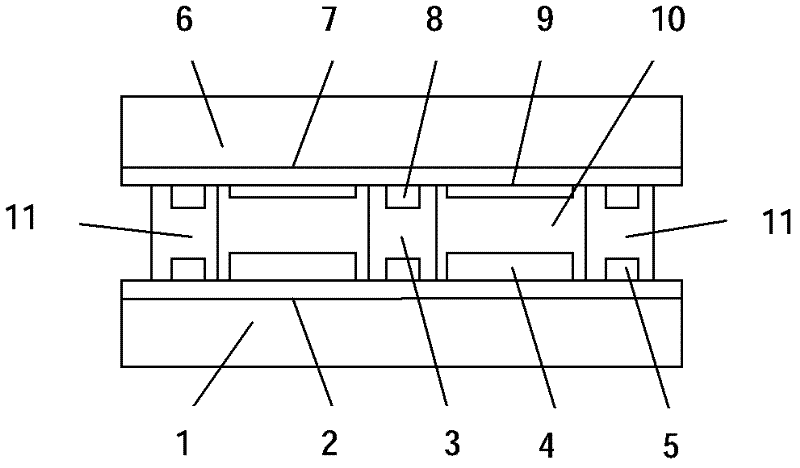

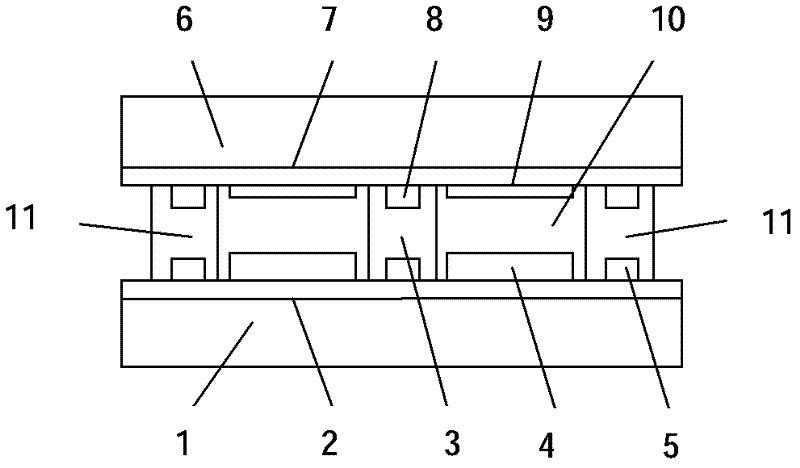

[0023] An optimized process for encapsulating dye-sensitized solar cells with low glass powder and protecting their silver grid electrodes, comprising the following steps:

[0024] 1) On the photoanode conductive glass substrate 1 and the counter electrode conductive glass substrate 6 with packaging holes punched, respectively print a layer of designed silver grid electrode 5 and silver grid electrode 8 patterns by the method of screen printing, and then sinter , the sintering temperature is 450°C, and the heat preservation time is 30min;

[0025] 2) Between the silver grid electrodes 5 on the photoanode conductive glass substrate 1, a titanium dioxide thin film 4 pattern is printed by screen, and then sintered at 450° C. for 25 minutes;

[0026] 3) On the silver grid electrode 5 pattern and the frame on the photoanode conductive glass substrate 1, screen-print the low glass powder paste, make the sealing frame 11 and the silver grid electrode protective layer 3 pattern, and d...

Embodiment 2

[0034] An optimized process for encapsulating dye-sensitized solar cells with low glass powder and protecting their silver grid electrodes, comprising the following steps:

[0035] 1) On the photoanode conductive glass substrate 1 and the counter electrode conductive glass substrate 6 with packaging holes punched, respectively print a layer of designed silver grid electrode 5 and silver grid electrode 8 patterns by the method of screen printing, and then sinter , the sintering temperature is 500°C, and the temperature is kept for 15 minutes;

[0036] 2) between the silver grid electrodes 5 on the photoanode conductive glass substrate 1, print the pattern of the titanium dioxide film 4 by screen printing, and then sinter, the sintering temperature is 500° C., and keep warm for 10 minutes;

[0037] 3) On the pattern of the silver grid electrode 5 and the frame on the photoanode conductive glass substrate 1, apply a low glass powder paste to make the sealing frame 11 and the patt...

Embodiment 3

[0045] An optimized process for encapsulating dye-sensitized solar cells with low glass powder and protecting their silver grid electrodes, comprising the following steps:

[0046] 1) On the photoanode conductive glass substrate 1 and the counter electrode conductive glass substrate 6 with packaging holes punched, respectively print a layer of designed silver grid electrode 5 and silver grid electrode 8 patterns by the method of screen printing, and then sinter , the sintering temperature is 450°C, and the heat preservation time is 20min;

[0047] 2) Between the silver grid electrodes 5 on the photoanode conductive glass substrate 1, a pattern of titanium dioxide film 4 is printed by screen, and then sintered at 480° C. for 20 minutes;

[0048]3) On the pattern of the silver grid electrode 5 and the frame on the photoanode conductive glass substrate 1, apply low glass powder paste, make the sealing frame 11 and the pattern of the silver grid electrode protective layer 3, and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com