Desulfurization and denitrification device based on adjusting type active particle exciters

An active particle, desulfurization and denitrification technology, which is applied in the field of desulfurization and denitrification devices based on adjustable active particle exciters, can solve the problems of accelerated flue corrosion, inaccurate ionization objects, and easy discharge of active particles, so as to reduce the heat transfer of flue gas Loss of capacity, improving efficiency and economy, and ensuring the effect of maximizing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

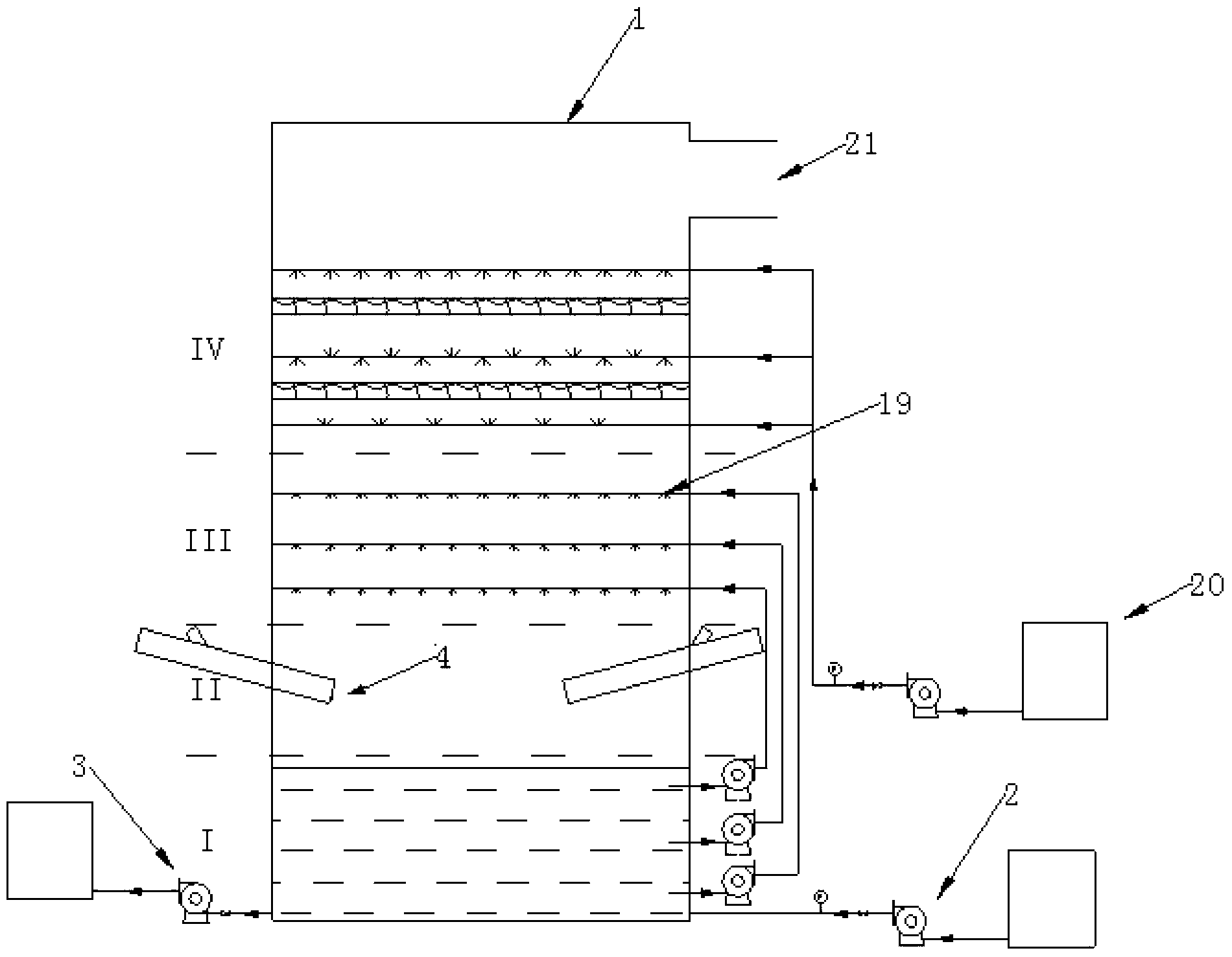

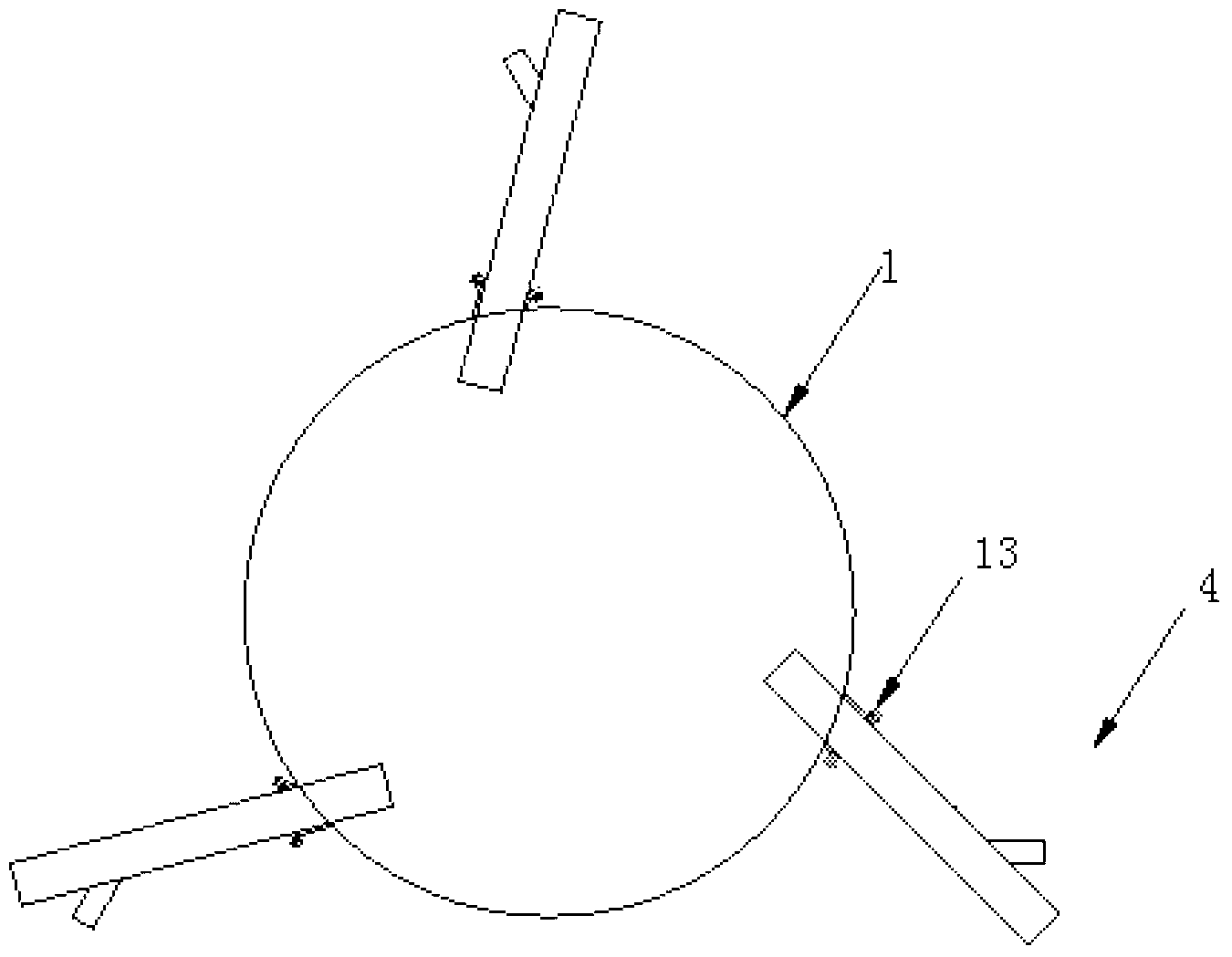

[0026] Such as figure 1 shown. The desulfurization and denitrification device based on the adjustable active particle exciter disclosed by the present invention includes an absorption tower 1, which is divided into absorption liquid pool area I, flue gas oxidation injection area II, and spray area III in order from bottom to top in the absorption tower 1 . Demisting zone IV, the flue gas oxidation injection zone II is composed of a plurality of active particle exciters 4 horizontally arranged tangentially along the wall of the absorption tower 1;

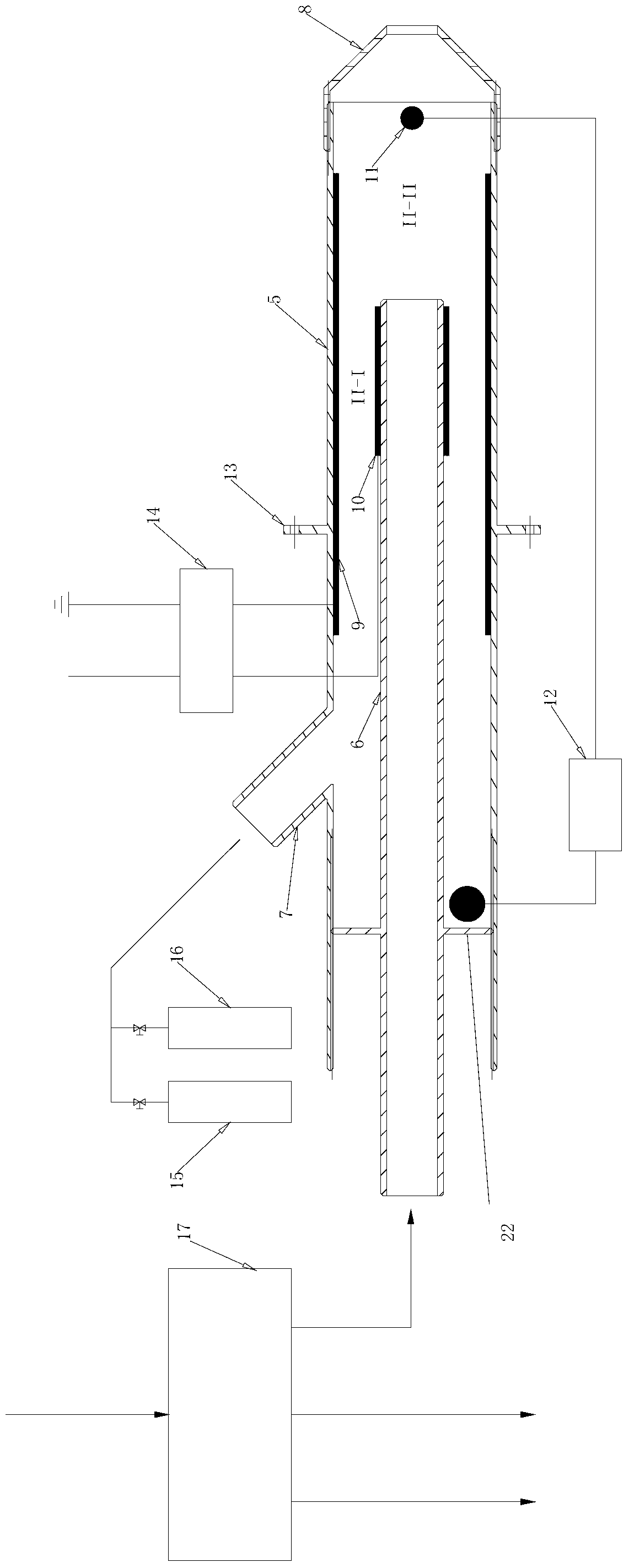

[0027] The active particle exciter 4 includes an outer tube 5, an inner tube 6 concentrically placed in the outer tube 5, the tail of the outer tube 5 is provided with an electrode gas bevel cut inlet pipe 7, the outer wall of the inner tube 6 and the inner wall of the outer tube 5 An annular channel is formed at intervals between each other; the end of the outer tube 5 is fitted with a nozzle 8; an embedded annular grounding elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com