Sb2Tey-Si3N4 composite phase change material for phase change memory and preparation method thereof

A composite phase-change material and phase-change memory technology, applied in the direction of electrical components, etc., can solve problems such as poor crystallization speed, difficult application, and reliability of devices that affect the erasing and writing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

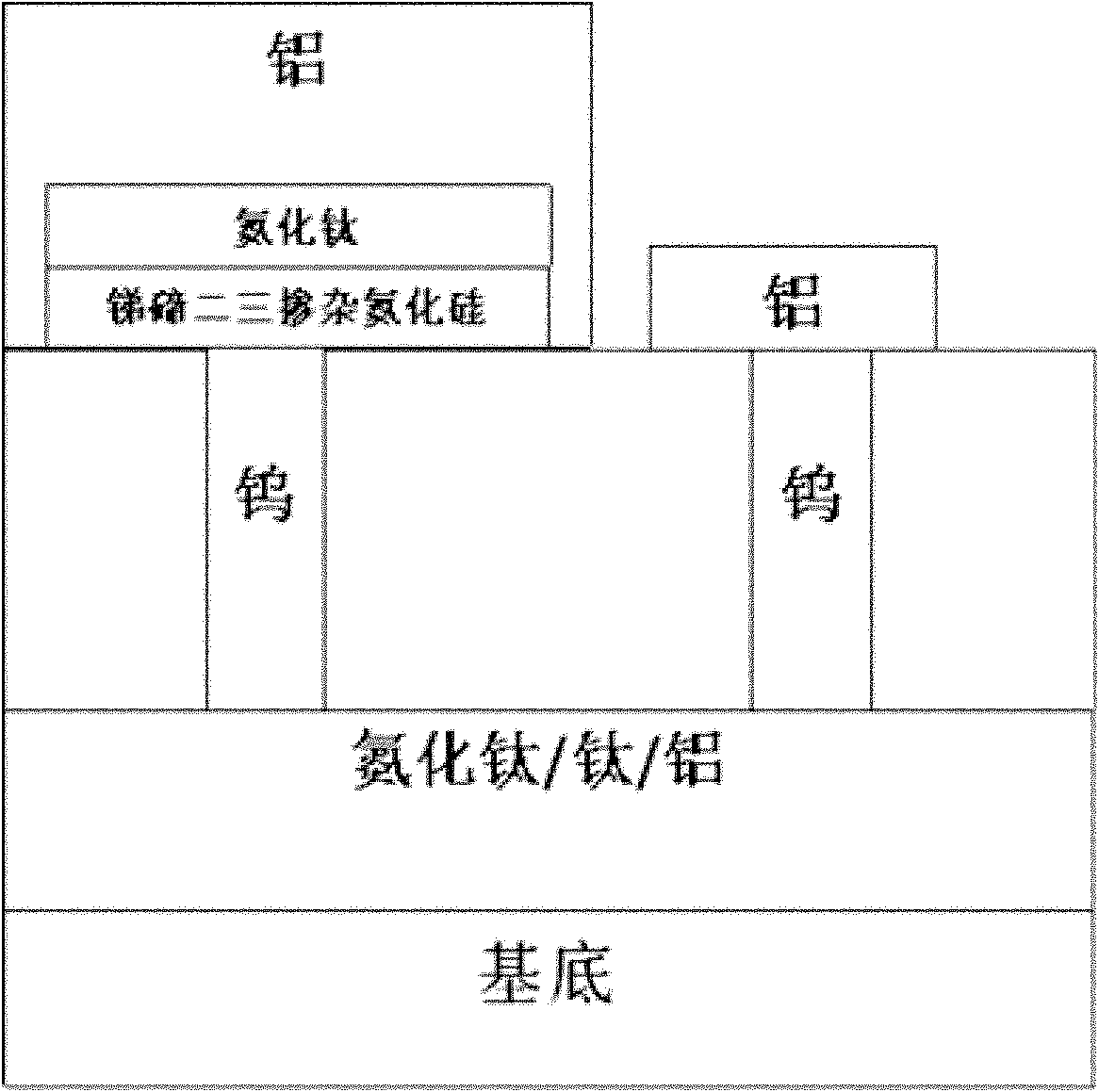

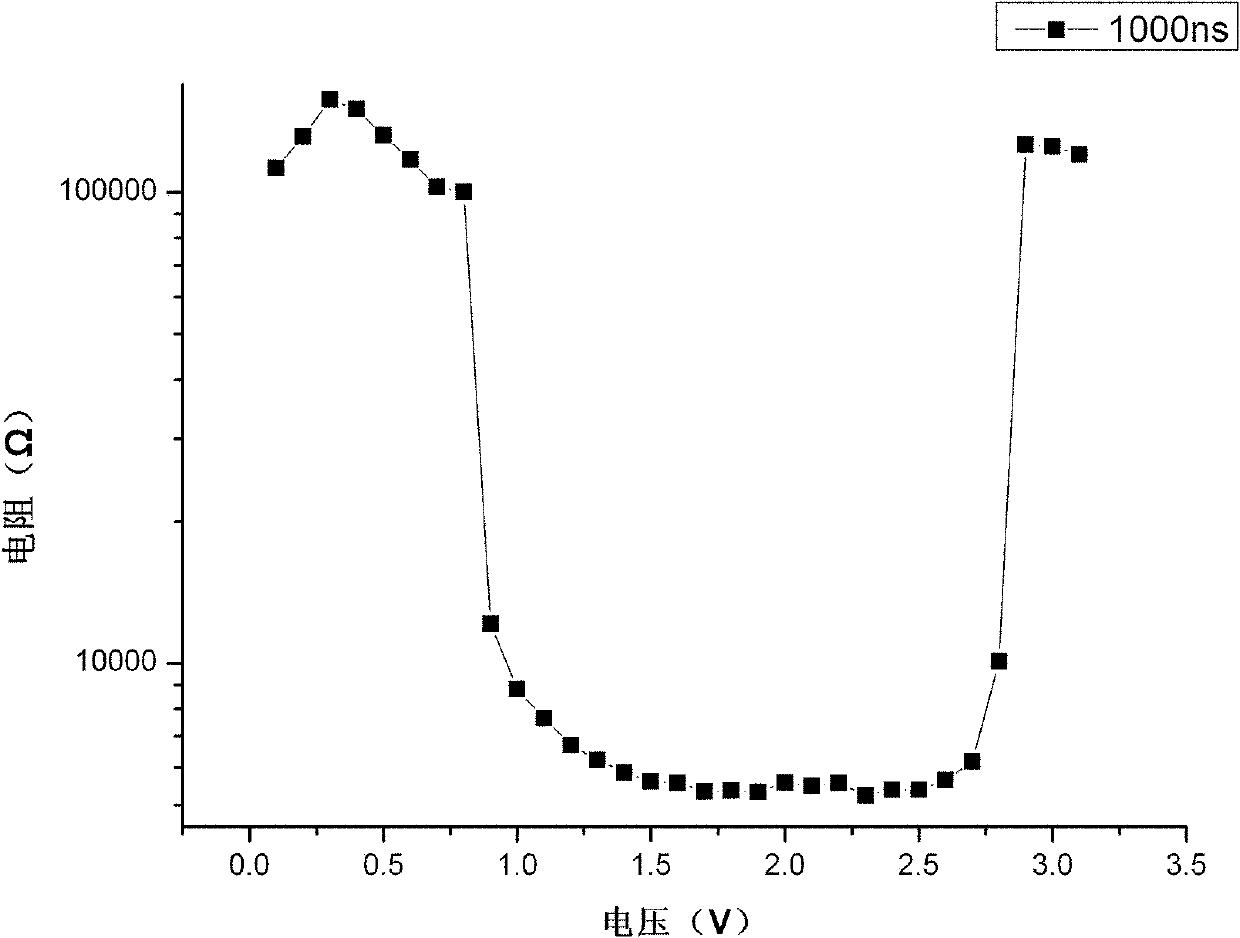

[0027] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

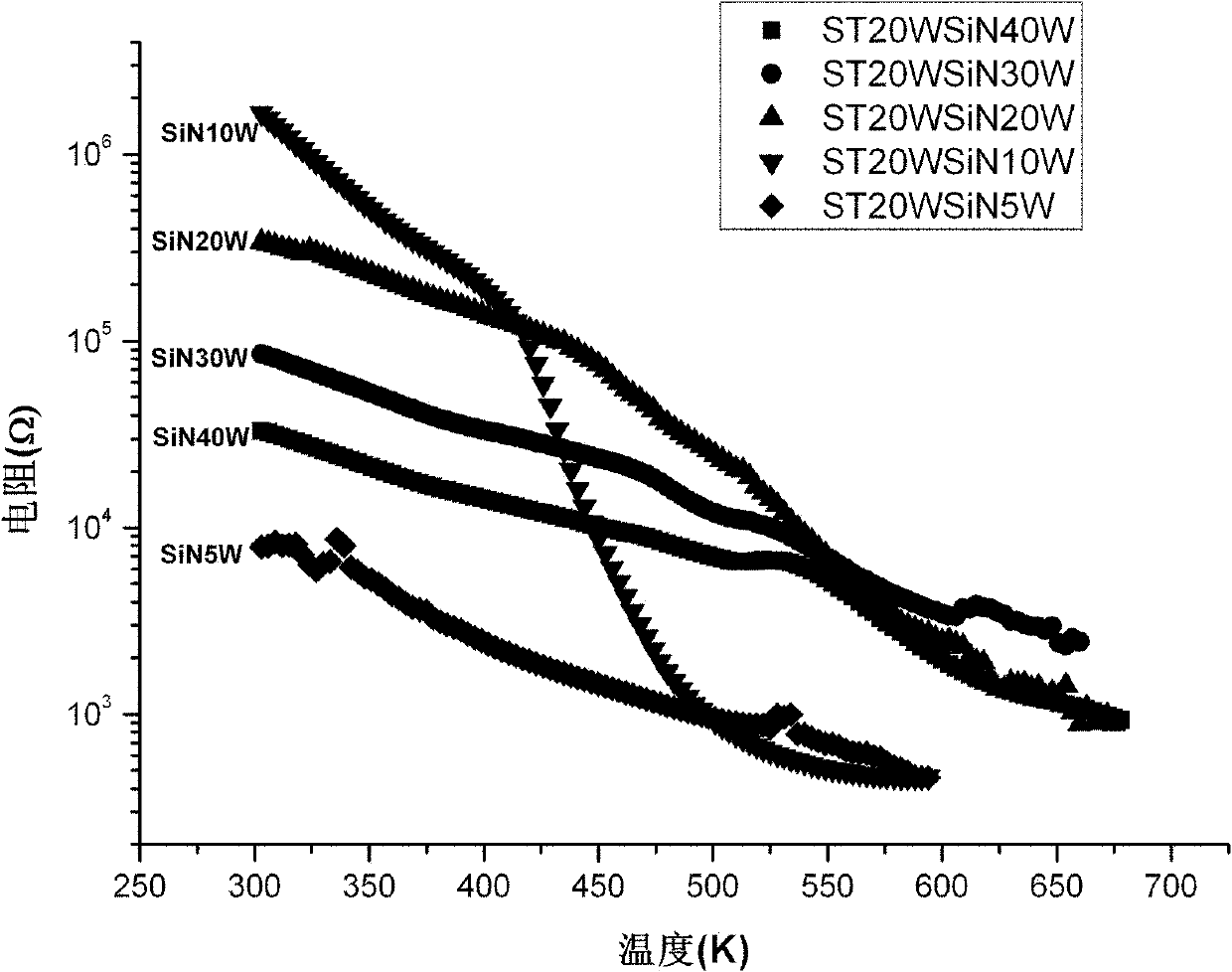

[0028] The present invention Sb 2 Te y -Si 3 N 4 Composite phase change materials can be prepared in various ways, such as magnetron sputtering and multi-target co-sputtering. For example, Sb 2 Te 3 、Si 3 N 4 Co-sputtering of two alloy targets, the composition can be adjusted by controlling the power of the two target positions, and Sb targets, Te targets and SiN targets can also be used 4 Alloy target for co-sputtering to prepare thin film, or use Sb target, Te target, Si target and N 2 Co-sputtering, these methods can be used to prepare phase change materials of various compositions. In this example, Sb 2 Te 3 target and Si 3 N 4 Target co-sputtering as an example to prepare thin film samples.

[0029] Using Sb 2 Te 3 target and Si 3 N 4 The method of target co-sputtering, in the process of co-sputtering, Ar gas with a puri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com