Amplifier and method for increasing multipass amplifying output power of bar-like Nd: YAG (yttrium aluminum garnet) laser

A technology of output power and amplifier, which is applied in the field of lasers, can solve problems such as the inability to reduce the thermal depolarization effect of laser amplifiers, affect the output power of solid-state lasers, and increase the thermal depolarization effect, so as to reduce the cost of lasers, facilitate engineering applications, and output The effect of power increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

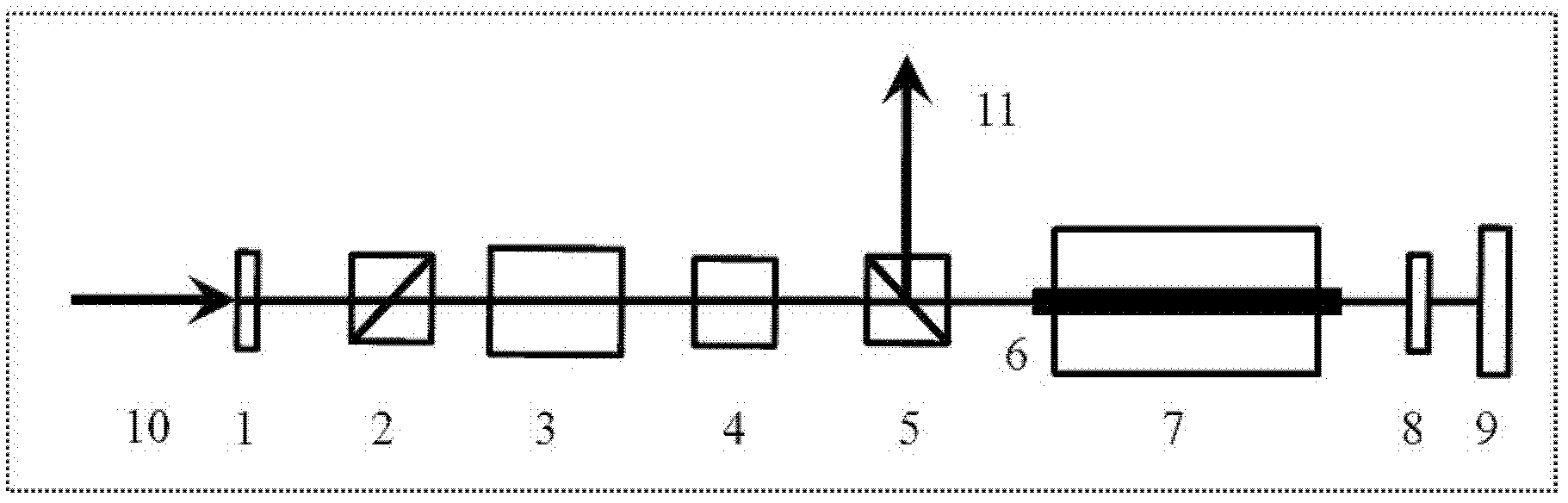

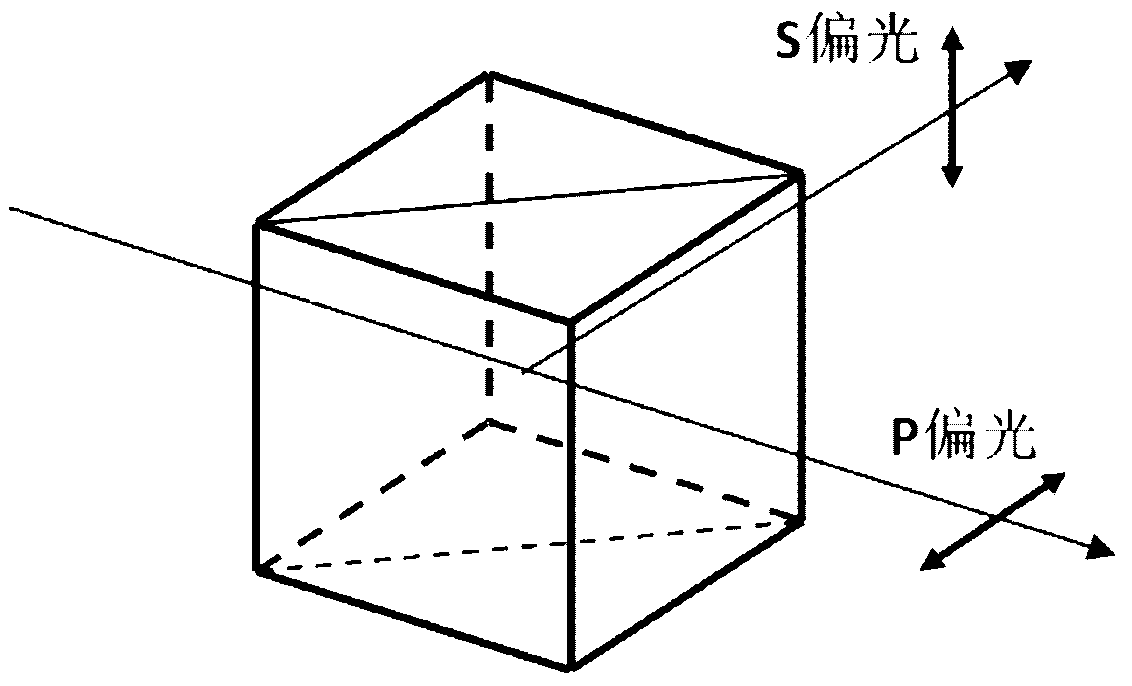

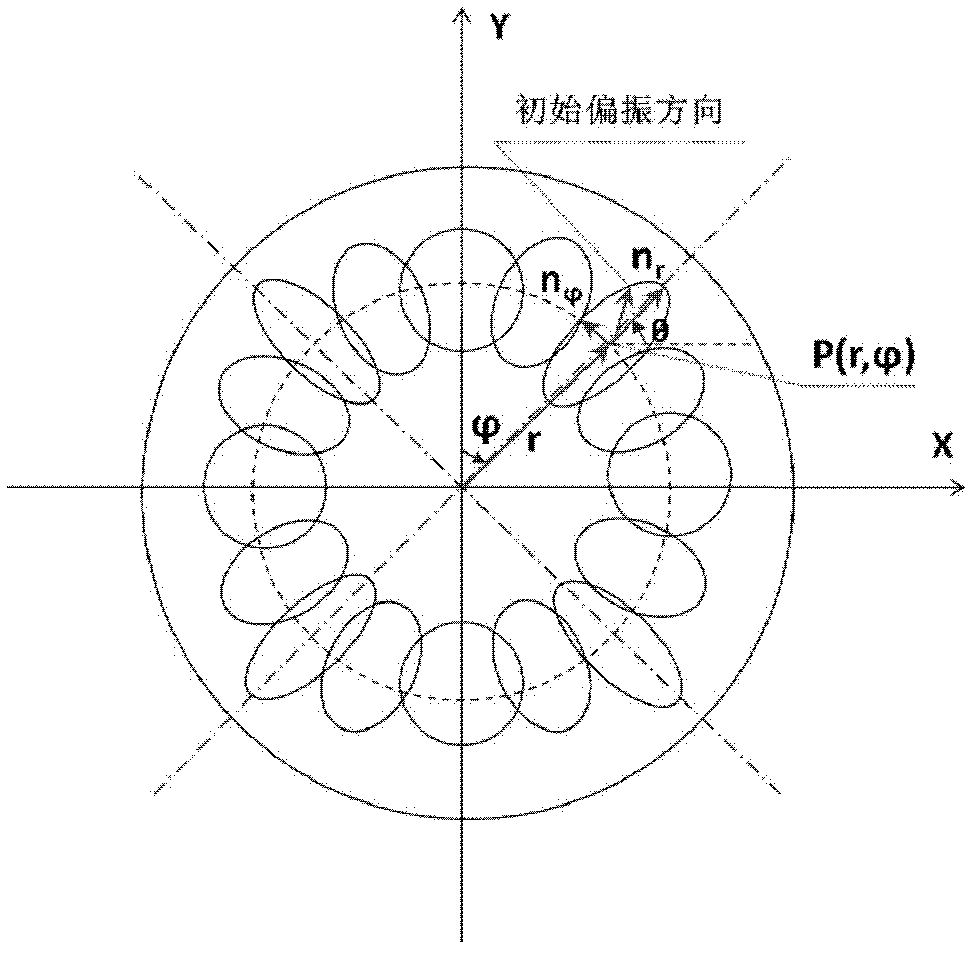

[0022] like figure 1 As shown, the present embodiment is composed of 1 / 2 wave plate (1), polarization beam splitter prism a (2), 45 degree Faraday rotator (3), 45 degree quartz rotator (4) and polarization beam splitter prism b (5) Sequential placement constitutes an optoisolator. The laser medium (6) is installed in the semiconductor laser module (7), and the laser medium (6) is a Nd:YAG crystal rod using the [100] cutting direction. After the seed light (10) is injected, it enters the laser medium through an optical isolator (6), plus 1 / 4 wave plate (8) and total reflection mirror (9) constitute the laser double-pass amplifier, below in conjunction with [111] and [100] direction cutting Nd: the thermal stress birefringence effect of YAG crystal, and The thermal depolarization effect generated by it will be further described in this embodiment.

[0023] The seed light (10) is a p-linearly polarized laser. After passing through the 1 / 2 wave plate (1), the phase is rotated by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com