Article formed using nanostructured ferritic alloy

A nanostructure, ferrite technology, applied in magnetic objects, magnetic circuits characterized by magnetic materials, transportation and packaging, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

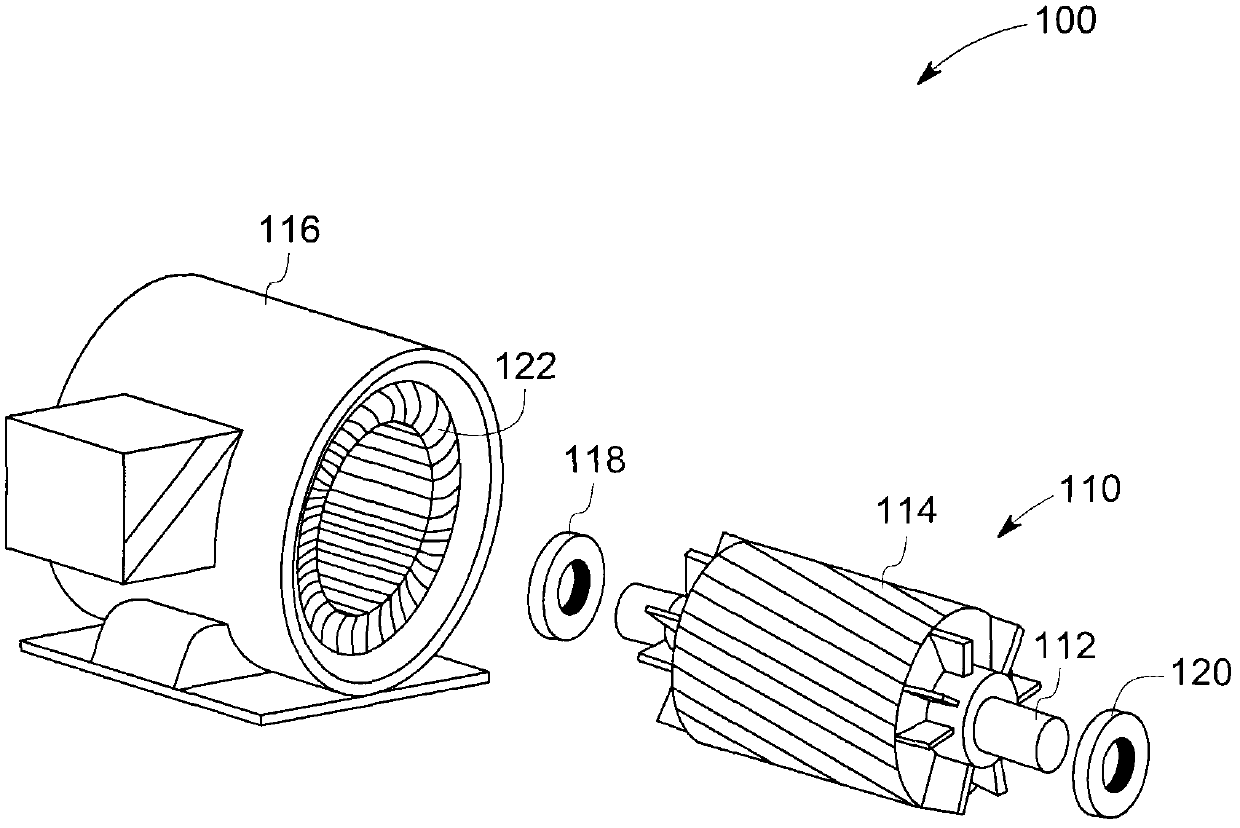

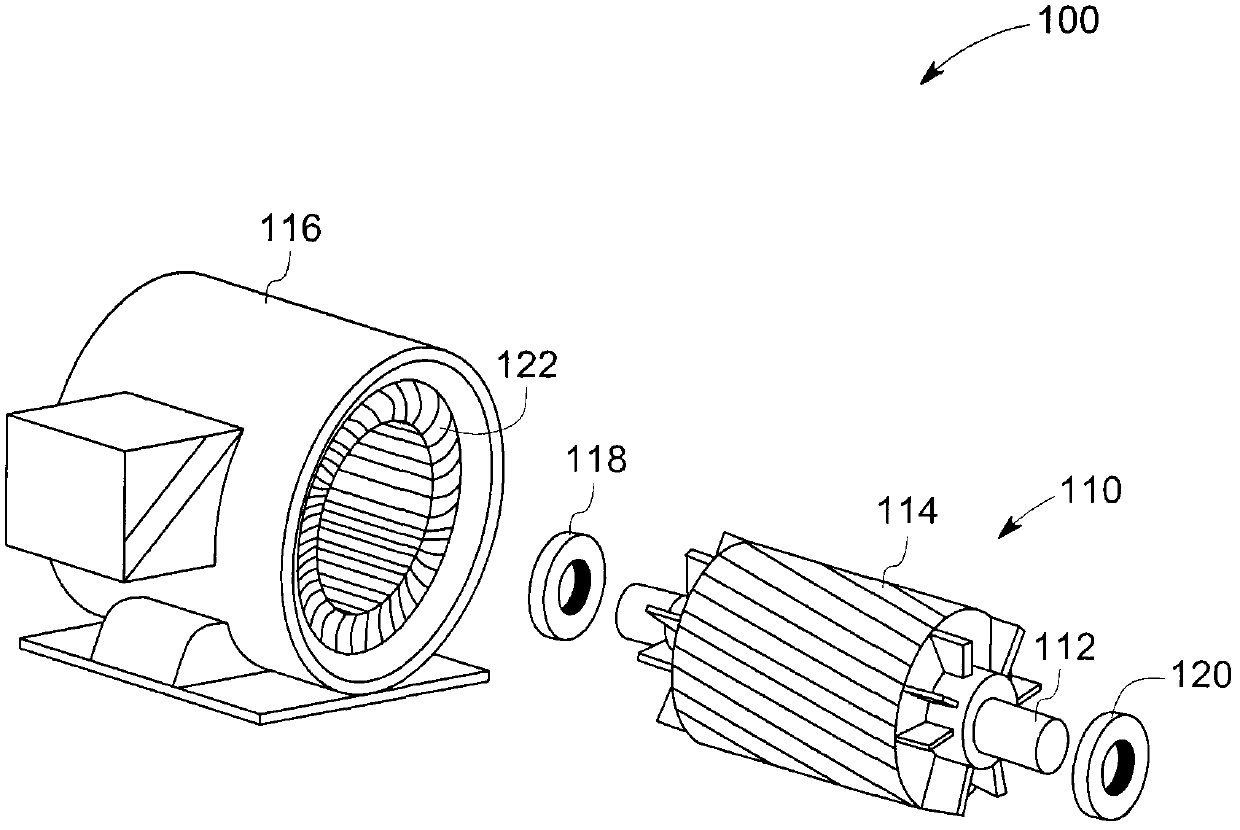

[0016] Magnetic materials with relatively high permeability, high saturation magnetization, low core loss, and high mechanical strength are required in many electrical devices and components used in many applications including aviation, wind power generation, and electric vehicles. There is a continuing need for soft magnetic components with improved magnetic properties and high mechanical strength. Embodiments of the invention described herein address significant shortcomings of the prior art. Products comprising soft magnetic elements are disclosed herein. Soft magnetic components contain nanostructured ferritic alloys. A nanostructured ferritic alloy includes a plurality of nanocomponents disposed within a ferrous alloy matrix, wherein the nanocomponents comprise an oxide. This product can be used in devices such as electric motors or generators that use magnetic materials in the rotating elements, where both mechanical integrity and magnetic properties can affect overall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com