Encapsulated stator assembly

A stator and component technology, which is applied to electric components, electrical components, magnetic circuit static parts, etc., can solve problems such as increasing the risk of thermal failure of motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

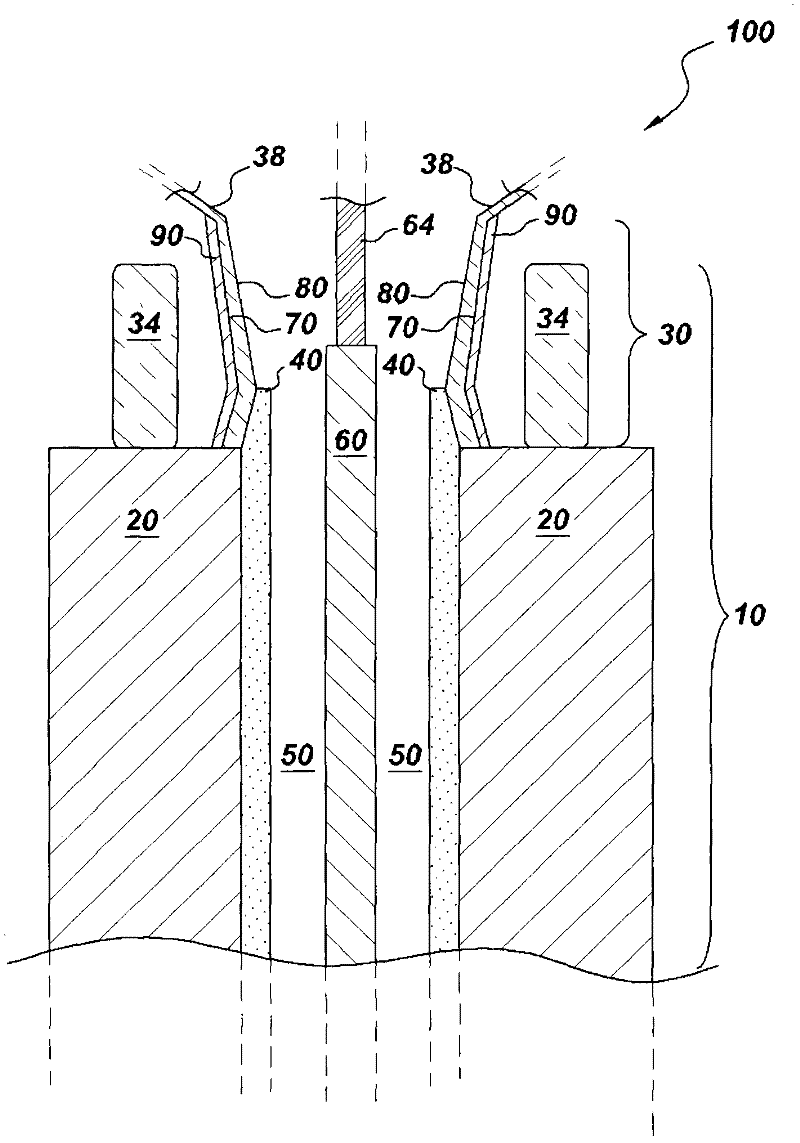

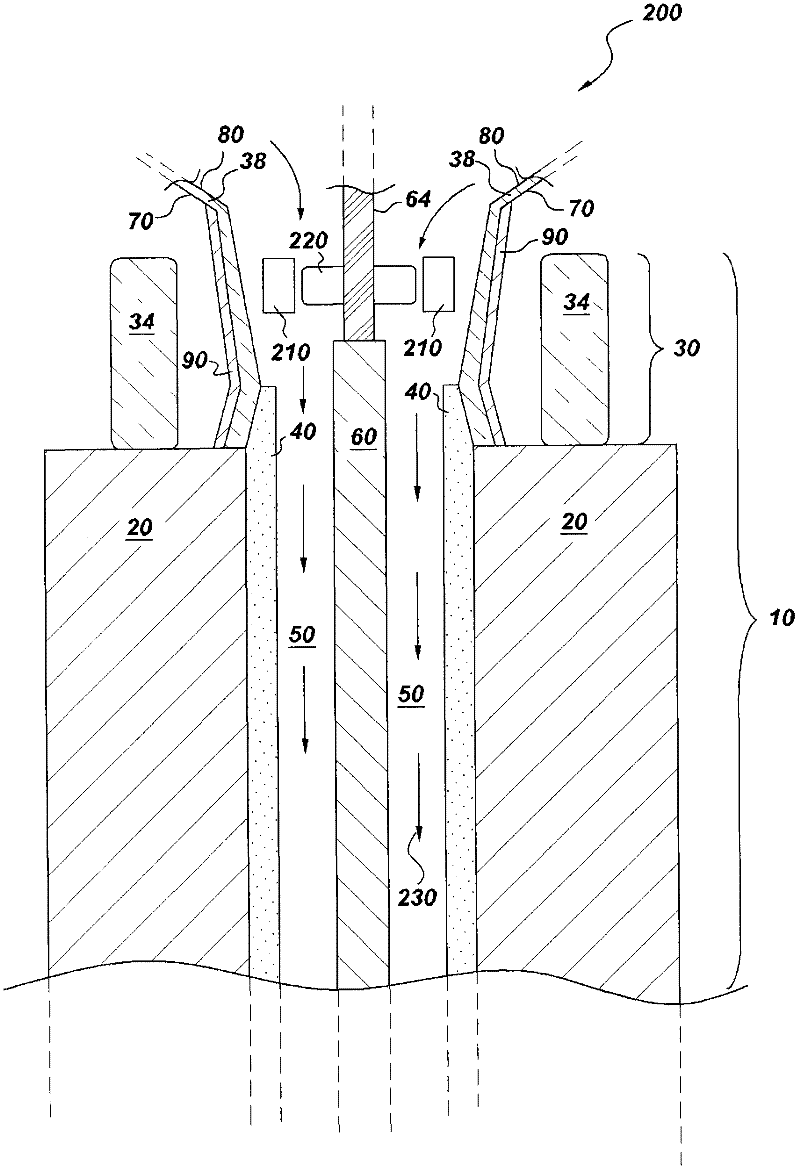

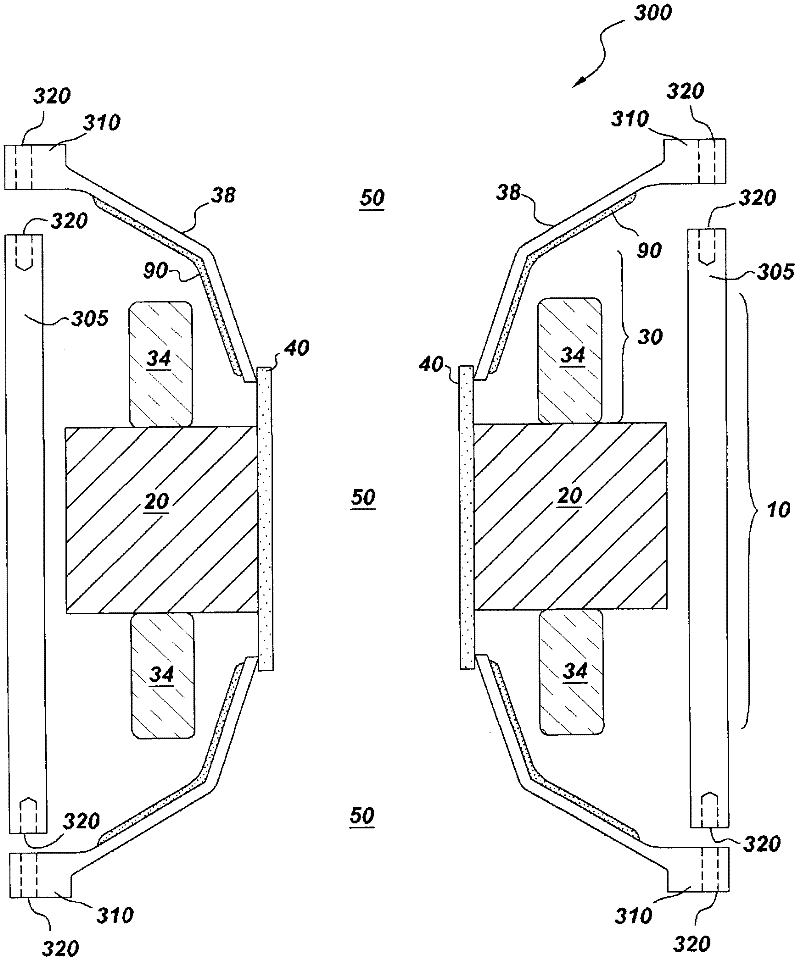

[0020] As noted, in one embodiment, the present invention provides an encapsulated stator assembly comprising: (a) a stator having a stator core and a stator end region; and (b) a ceramic bore tube, the ceramic bore tube defines a surface of the stator core; wherein the stator end region is disposed adjacent the stator core, and wherein the stator end region comprises a plurality of stator armature end windings, and wherein the stator end region comprises an inwardly facing stator wall, and wherein the ceramic bore tube and an inwardly facing stator wall define an interior volume configured to house the rotor, the inwardly facing stator wall having an inner surface and an outer surface, at least a portion of the inner surface comprising copper, silver and a barrier layer made of a conductive metal from the group consisting of aluminum, the inwardly facing stator wall contains a corrosion resistant metal.

[0021] The encapsulated stator assemblies provided by the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com