Method and device for removing electromagnetic induction type metallic surface coating

A metal surface and coating removal technology, applied in the direction of induction heating, induction heating control, induction heating device, etc., can solve the problem of large waste, and achieve the effect of convenient maintenance, fast speed and small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

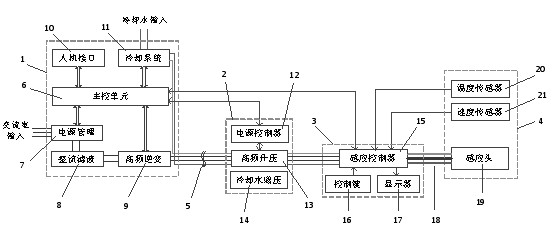

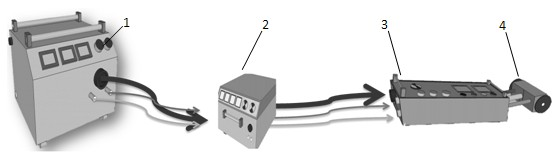

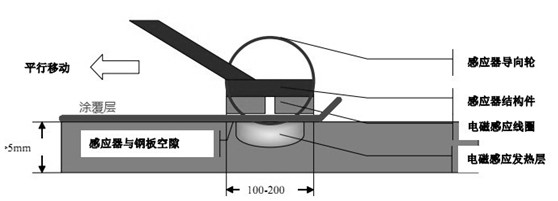

[0021] Such as figure 1 with figure 2 As shown, an electromagnetic induction type metal surface coating removal equipment provided by the present invention includes an induction power host 1, a relay power sub-machine 2, a hand-held sensor 3 and a replaceable induction head 4, and a connection with the induction power host 1 A dedicated high-frequency power cable with water cooling device and magnetic shielding device for the relay power sub-machine 2, and a dedicated high-frequency power cable with water cooling device and magnetic shielding device for connecting the relay power sub-machine 2 and the hand-held sensor 3 , connecting the relay power sub-machine 2 and the induction power host 1, the hand-held sensor 3 and the dedicated data cable of the induction power host 1.

[0022] Induction power host 1 is used to provide power for the entire device, cooling water circulation and purification, parameter setting, operation monitoring, and remote control of relay power sub-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com