Device and method for producing runner-containing part of fusion reactor cladding by utilizing explosive cladding

A technology for flow channel components and fusion reactors, applied in non-electric welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of secondary deformation, complicated procedures, affecting the dimensional accuracy of the flow channel, and reduce the difference in wave impedance. , the effect of ensuring overall strength and integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

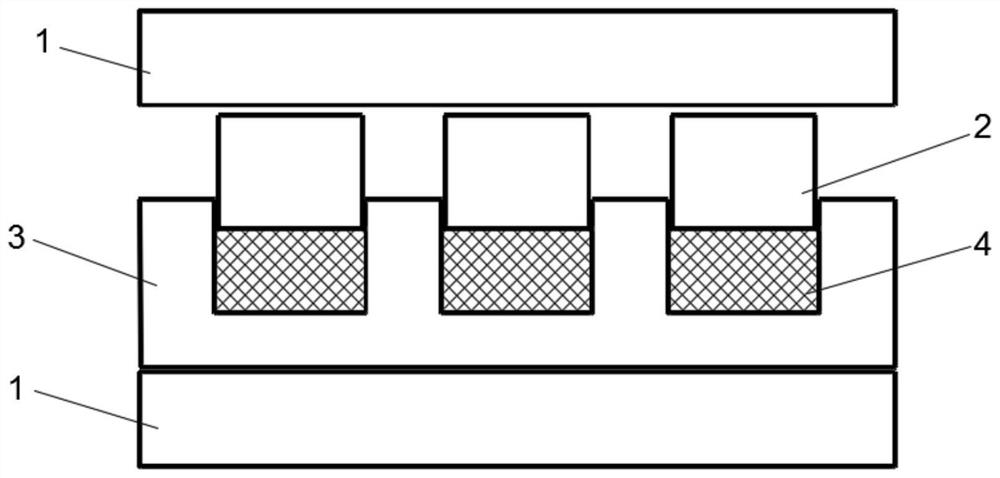

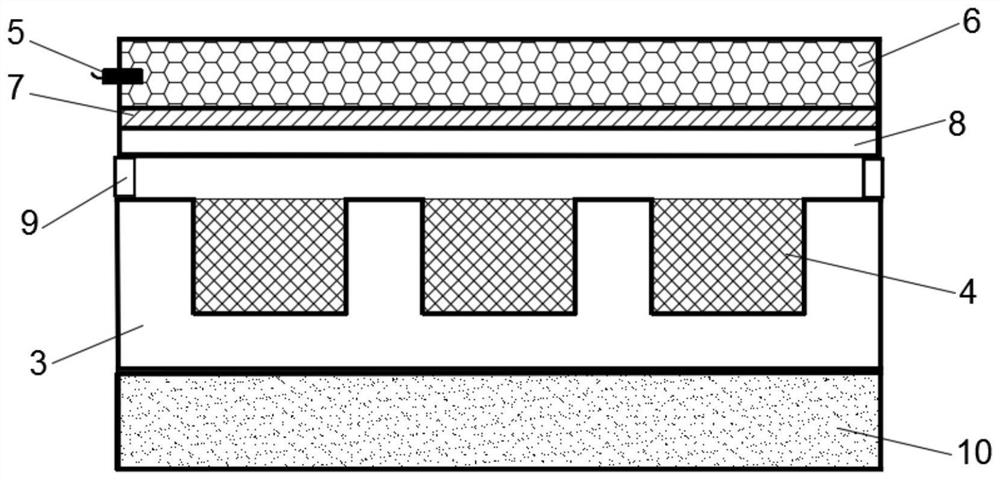

[0025] A device for explosive composite production of flow path components in the cladding of a fusion reactor, including: a jack 1, a metal bead 2, a launder 3, a mixed filler of weak acid and weak base salt powder and low melting point metal particles 4, a detonator 5, and an explosive layer 6. PVC foam board buffer layer 7, cover plate 8, support column 9 rolled by metal foil and sandy ground 10, wherein, the pressure head of jack 1 is located above the metal bead 2, and it is in contact with the upper surface of the metal bead 2 during work. Close fit, by applying pressure to the metal bead 2, the mixed filler 4 of weak acid and weak base salt powder and low melting point metal particles is fully compacted; the side wall of the metal bead 2 is closely tangent to the inner wall of the launder 3 After receiving the pressure of the jack 1, the mixed filling 4 of weak acid and weak base salt powder and low melting point metal particles is compressed; the detonator 5 is arranged...

Embodiment 2

[0027] A method for explosive recombination production of flow channel components in the cladding of a fusion reactor, comprising the following steps:

[0028] (1) Mechanically mill out the shape of a straight rectangular flow channel on the plate, and process the rectangular metal bead covering the plate and the same cross-section but higher than the flow channel;

[0029] (2) Use a grinder and sandpaper to smooth the surface of the launder and the doubler plate to be compounded, and wipe with alcohol to decontaminate;

[0030] (3) As attached figure 1 As shown, the launder 3 is placed in the jack 1, the launder 3 is a launder plate of any shape, the launder is filled with a mixed filler 4 of weak acid and weak alkali salt powder and low melting point metal particles, and the metal bead 2 is placed Right above the launder, control the pressure of the jack 1 to 5MPa, repeat the process of filling and compacting until the surface of the filler is flush with the upper surface o...

Embodiment 3

[0036] A method for explosive recombination production of flow channel components in the cladding of a fusion reactor, comprising the following steps:

[0037] (1) Mechanically mill out the U-shaped flow groove shape on the plate, and process the U-shaped metal bead covering the plate and the same cross-section but higher than the flow groove;

[0038] (2) Use a grinder and sandpaper to smooth the surface of the launder and the doubler board to be compounded, and wipe with alcohol to decontaminate;

[0039] (3) As attached figure 1 As shown, the launder 3 is placed in the jack 1. The launder 3 is a launder plate of any shape. The launder is filled with a mixed filler 3 of weak acid and weak alkali salt powder and low melting point metal particles, and the metal bead 2 is placed Directly above the launder, control the pressure of jack 1 to 5MPa, repeat the process of filling and compacting until the surface of the filling is flush with the upper surface of the launder, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com