Wet efficient mote recycling and purifying method and device for ceramic industry

An industrial and wet technology, applied in the direction of chemical instruments and methods, separation methods, combined devices, etc., can solve the problems of unsustainable economic development and social unaffordability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples.

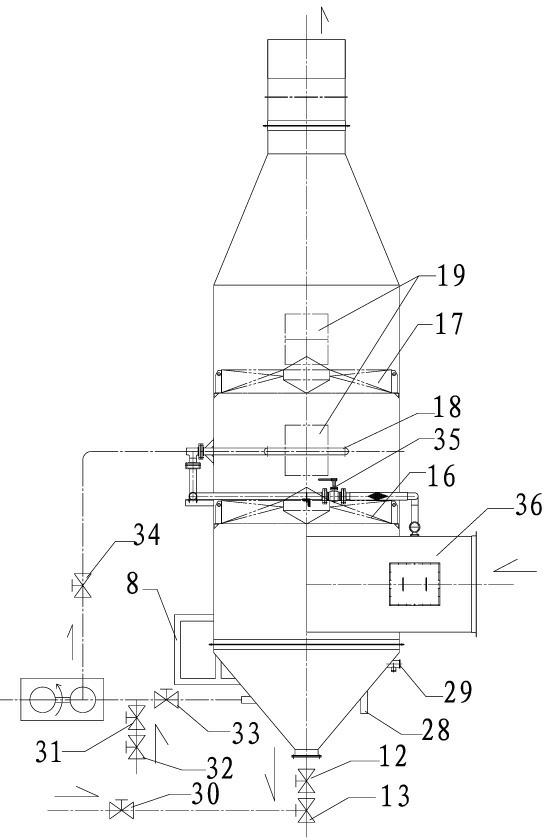

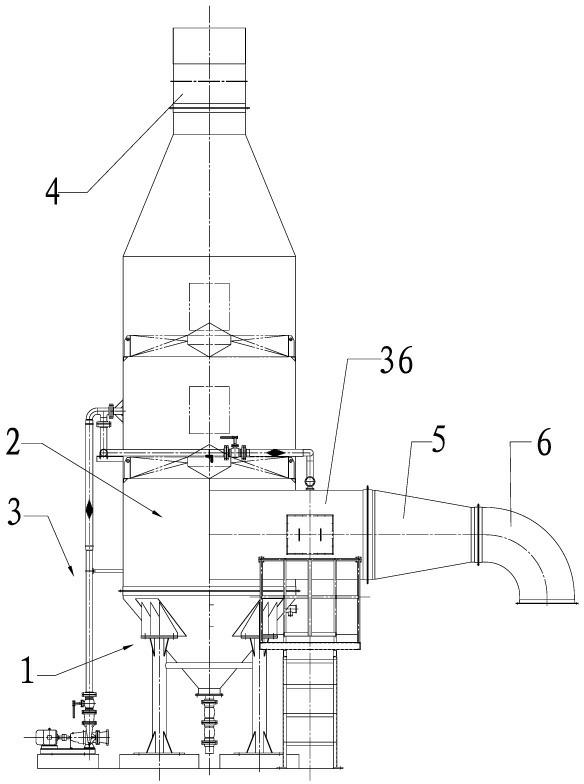

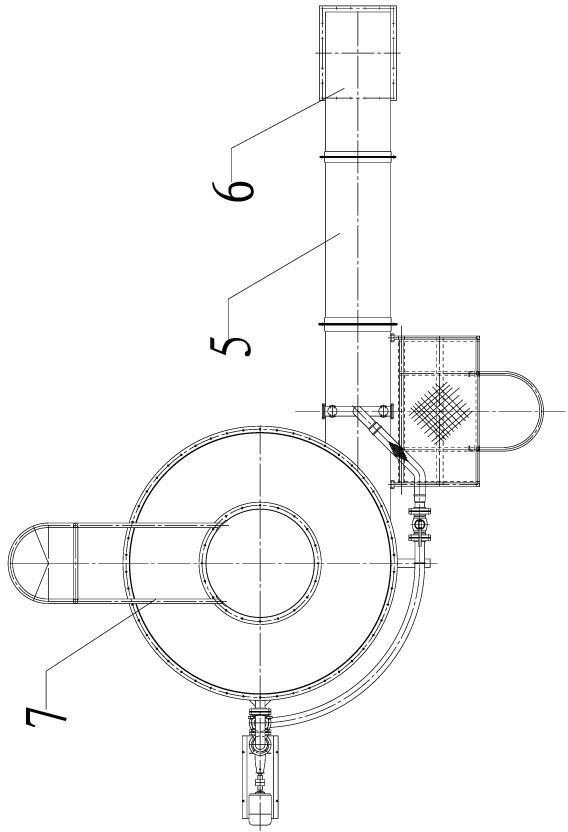

[0021] See attached figure 1 to attach Figure 9 As shown, the wet-type high-efficiency recovery and purification fine dust device for the ceramic industry described in this embodiment is mainly to recover and purify the fine powder and other impurities in the flue gas produced by the ceramic industry (mainly referring to SO 2 It is known in the industry that the exhaust hot air after rough dust removal still contains a small amount of fine dust and other impurities. These exhaust hot air containing a small amount of fine dust and impurities must be further dedusted and purified before they can be discharged up to the standard; The wet-type high-efficiency recovery and purification of fine dust device is designed to solve this problem. It includes a lower cone part 1, a dust removal system 2, a water circulation system 3, a chimney 4, a conical connection 5, a square elbow 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com