Preparation method for high-performance metal organic framework film

A metal-organic framework, high-performance technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve uniform pore size distribution, easy operation, and increase the effect of heterogeneous nucleation points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

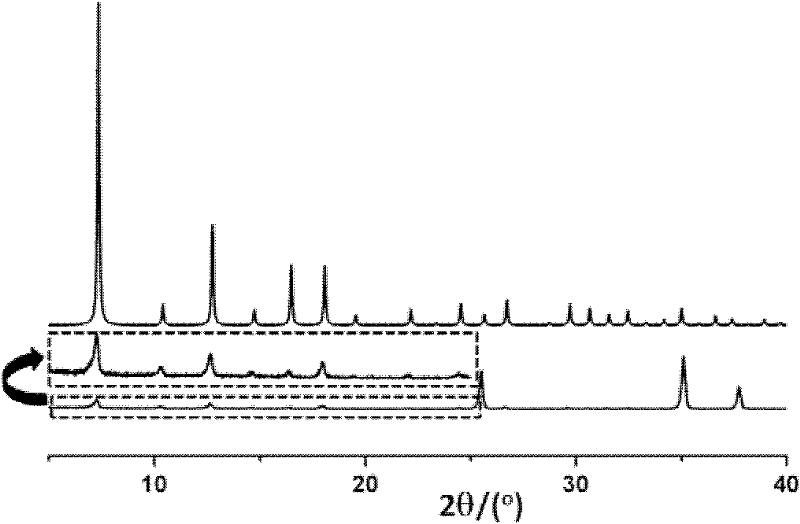

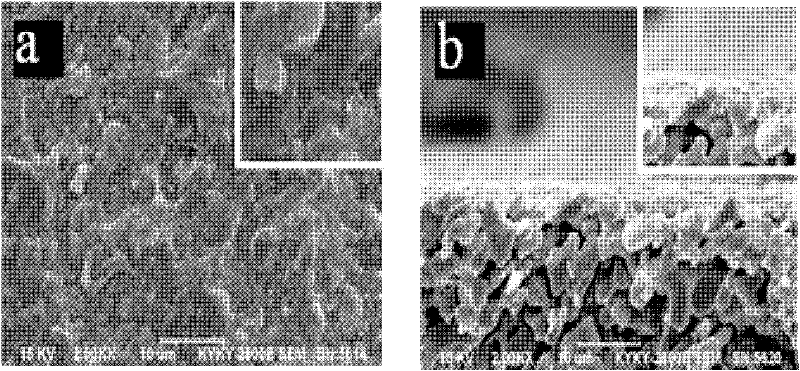

[0026] Example 1α-Al 2 o 3 Preparation of modified ZIF-8 membrane

[0027] Al with an average pore size of 2-3 μm 2 o 3 Polish the outer surface of the tubular carrier with 800# and 1200# sandpaper in turn until the surface of the carrier is smooth, soak in acid and alkali for 24 hours, then use ultrasonic vibration to wash away the residual alkali in the hole, then wash it with deionized water until it is neutral, and then dry it naturally , Finally, after calcining at a high temperature of 550°C for 6 hours, seal the two ends.

[0028] N 2 Under protection, weigh 5 g of α-Al with a pore size of 0.5-0.6 μm 2 o 3 Add 150ml of anhydrous toluene, heat to 120°C and add 4ml of APTES to react for 24 hours. After the reaction is completed, add 100ml of water to sonicate for 10 minutes and let it stand for 30 minutes. Remove the toluene in the upper layer and centrifuge at 8000 rpm for 5 minutes. After washing twice, put it in 50 °C drying in an oven to obtain silane coupling ...

Embodiment 2

[0033] The preparation of the ZIF-8 film of embodiment 2NaA modification

[0034] The average pore size is 2-3μm Al 2 o 3 Polish the outer surface of the tubular carrier with 800# and 1200# sandpaper in turn until the surface of the carrier is smooth, soak in acid and alkali for 24 hours, then use ultrasonic vibration to wash away the residual alkali in the hole, then wash it with deionized water until it is neutral, and then dry it naturally , Finally, after calcining at a high temperature of 550°C for 6 hours, seal the two ends.

[0035] N 2 Under protection, weigh 5g of NaA with a pore size of 2μm and add it to 150ml of anhydrous toluene. After heating to 120°C, add 4ml of APTES to react for 24h. After the reaction is completed, add 100ml of water and ultrasonic for 10min. Centrifuge for 5 minutes, wash twice with water, and then dry in an oven at 50°C to obtain silane coupling agent-formed inorganic particles I.

Embodiment 3

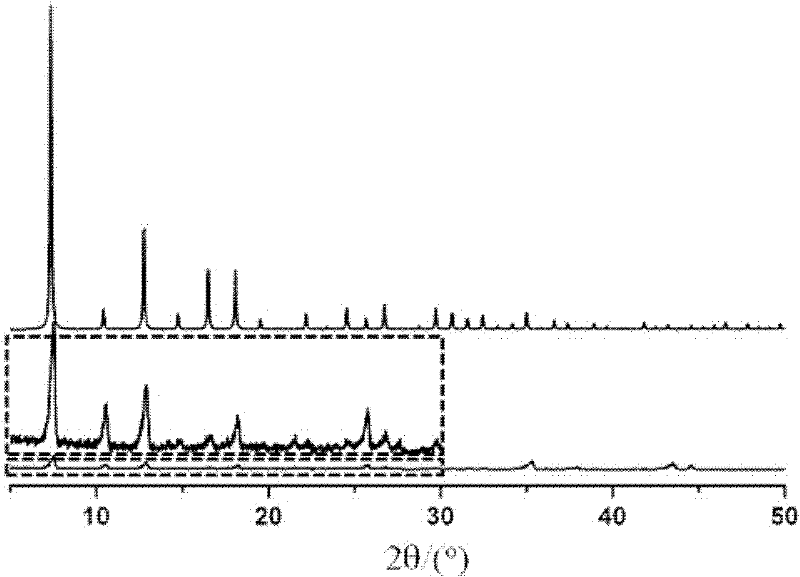

[0040] Example 3α-Al 2 o 3 Preparation of modified ZIF-7 membrane

[0041] Al with an average pore size of 2-3 μm 2 o 3 Polish the outer surface of the tubular carrier with 800# and 1200# sandpaper in turn until the surface of the carrier is smooth, soak in acid and alkali for 24 hours, then use ultrasonic vibration to wash away the residual alkali in the hole, then wash it with deionized water until it is neutral, and then dry it naturally , Finally, after calcining at a high temperature of 550°C for 6 hours, seal the two ends.

[0042] N 2 Under protection, weigh 5 g of α-Al with a pore size of 0.5-0.6 μm 2 o 3 Add 150ml of anhydrous toluene, heat to 120°C and add 4ml of APTES to react for 24 hours. After the reaction is completed, add 100ml of water to sonicate for 10 minutes and let it stand for 30 minutes. Remove the toluene in the upper layer and centrifuge at 8000 rpm for 5 minutes. Wash twice and place at 50°C Dry in an oven to obtain silane coupling agent-based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com