Method for determining effect of strip shape execution mechanism of metal strips

An actuator and metal strip technology, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of difficult modeling, complicated calculation, and tedious analysis, so as to ensure calculation accuracy, simple calculation method, The effect of reducing development investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

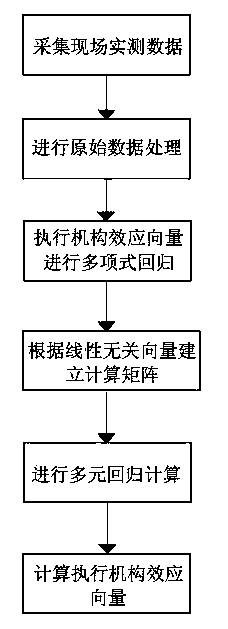

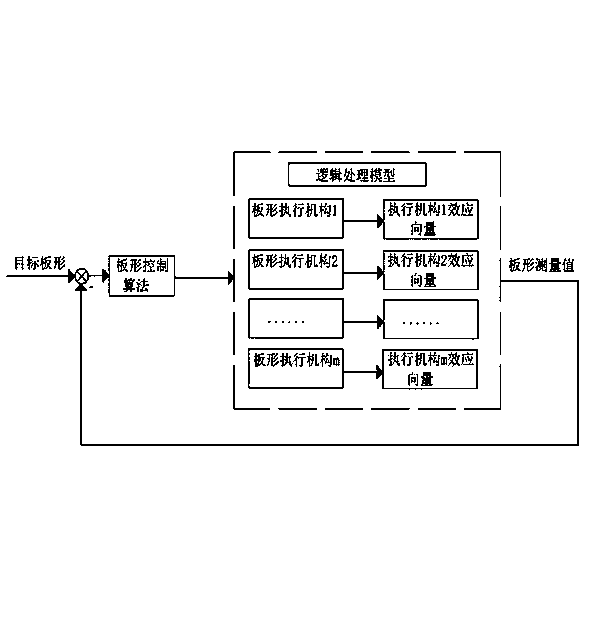

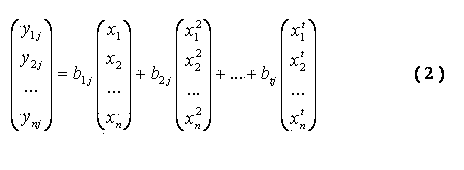

[0040] Such as figure 1 As shown, the method used to determine the effect of the metal strip shape actuator, firstly, the measurement of the actual rolling process on site, collect the field measured data, obtain the shape measurement value and the output value of the shape actuator; then, the original data processing , due to the noise and the characteristics of the actuator, the original collected data is filtered and normalized to obtain effective field data; furthermore, polynomial regression is performed on the effect vector of the actuator to determine the order of the polynomial; then, according to the effect The linear irrelevant vector in the vector establishes a calculation matrix; then, according to the calculation matrix, multiple regression analysis is performed to calculate the regression parameters; finally, the actuator effect vector is calculated according to the regression parameters.

[0041] The measurement of the actual rolling process on site is carried o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com