Method for machining inner gear rings

A processing method and the technology of the inner ring gear, which are applied in the processing field of the inner ring gear, can solve the problems of backward heat treatment technology, high processing cost, and low surface hardness, and achieve the goal of ensuring the deformation of the ring gear, reducing the processing cost, and improving the surface hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

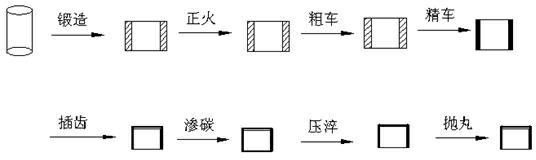

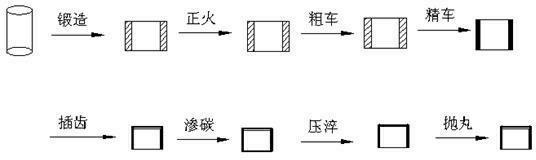

[0008] Such as figure 1 As shown, the present invention provides a processing method for an inner ring gear, which includes the following steps: Step 1, forging, select low-carbon alloy steel 20CrMnTiH material, reserve a margin according to the requirements of the drawings, and forge to form; Step 2, normalize , using isothermal normalizing technology, the normalizing temperature is 920-930°C, the isothermal temperature is 600-650°C, and the hardness after isothermal normalizing is 160-200HBW, which can eliminate the bad structure produced by forging and make the structure uniform; step 3, rough Turning, removing a large amount of allowance, and preliminarily forming the outer circle, hole, and end face; step 4, finishing turning, forming the outer circle, hole, end face, and seam according to the technical requirements; step 5, shaping the inner gear The tooth shape of the ring is processed and formed, and the tooth shape accuracy is guaranteed to be within 8 grades; Step 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com