Sapphire slice electric swing mechanism

A technology of swing mechanism and sapphire, applied in the field of swing mechanism and electric swing mechanism, can solve the problems of slow cutting, large contact area of cutting line, long cutting time, etc., and achieve the effect of ensuring angle and coordination and improving cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

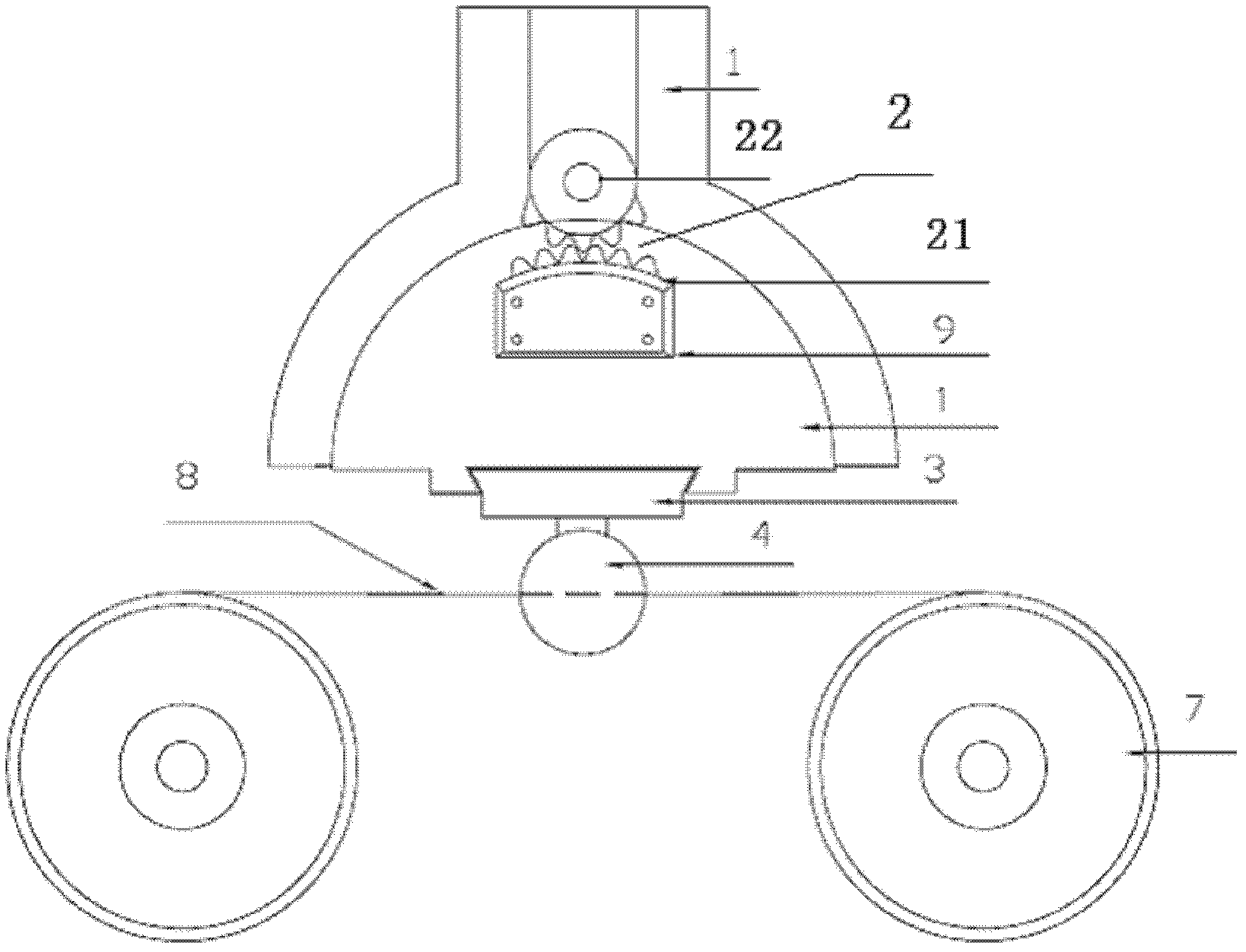

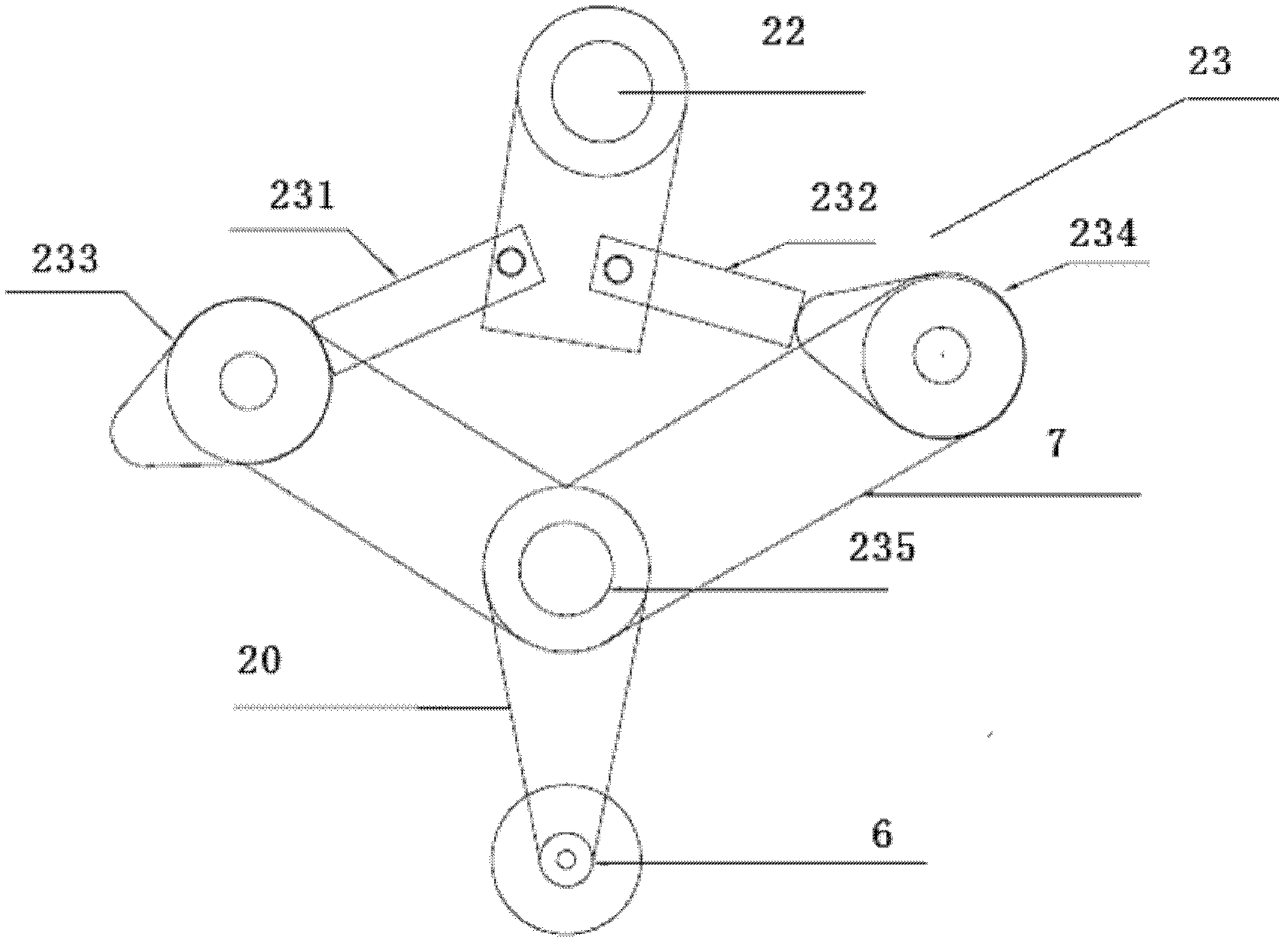

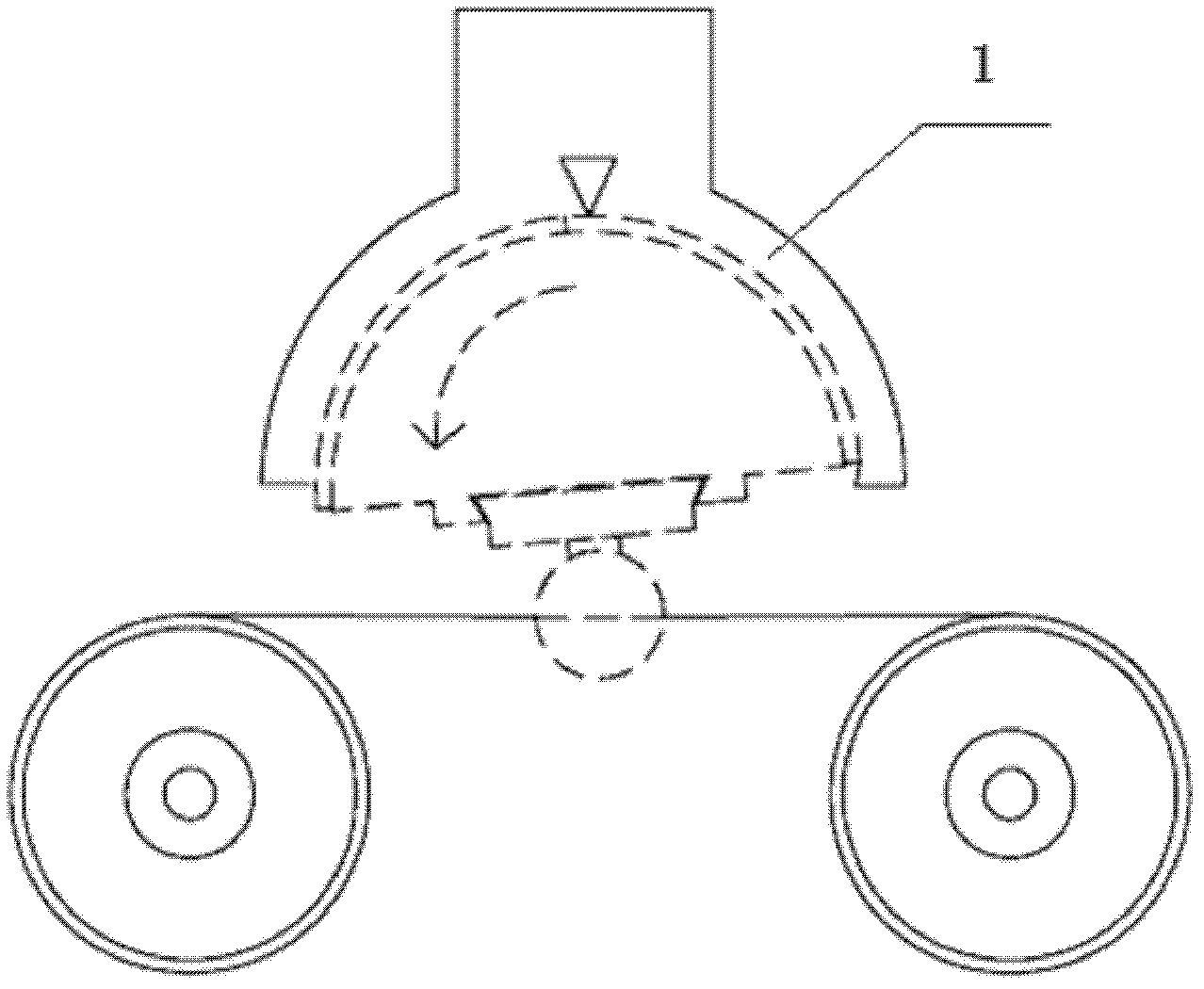

[0014] As shown in the figure, in order to solve the above-mentioned technical problems, an electric oscillating mechanism for sapphire slices of the present invention includes an oscillating head 1 and an oscillating device 2. Crystal bar 4; the swing device 2 is arranged in the swing head 1, and the swing device 2 includes arc-shaped teeth fixed on the swing head 1 by fasteners and rack holders 9 or other means Bar 21, swing member 22 and driving device 23, swing member 22 is a bar-shaped member, the upper end of swing member 22 is arranged on the upper end of swing head 1 through swing shaft 5, and the lower end of swing member 22 is provided with gear 221, and described gear 221 and The arc-shaped racks 21 are meshed. In order to ensure the accuracy of the meshing, the gear 221 can be designed as an arc-shaped gear. When working, the driving device 23 drives the swing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com