Rapid automatic control die plate locking system especially used for carton printing die cutting machine

A die-cutting machine, fast technology, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of low degree of automation and inconvenient operation, and achieve the effect of saving the number of workers, improving efficiency, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

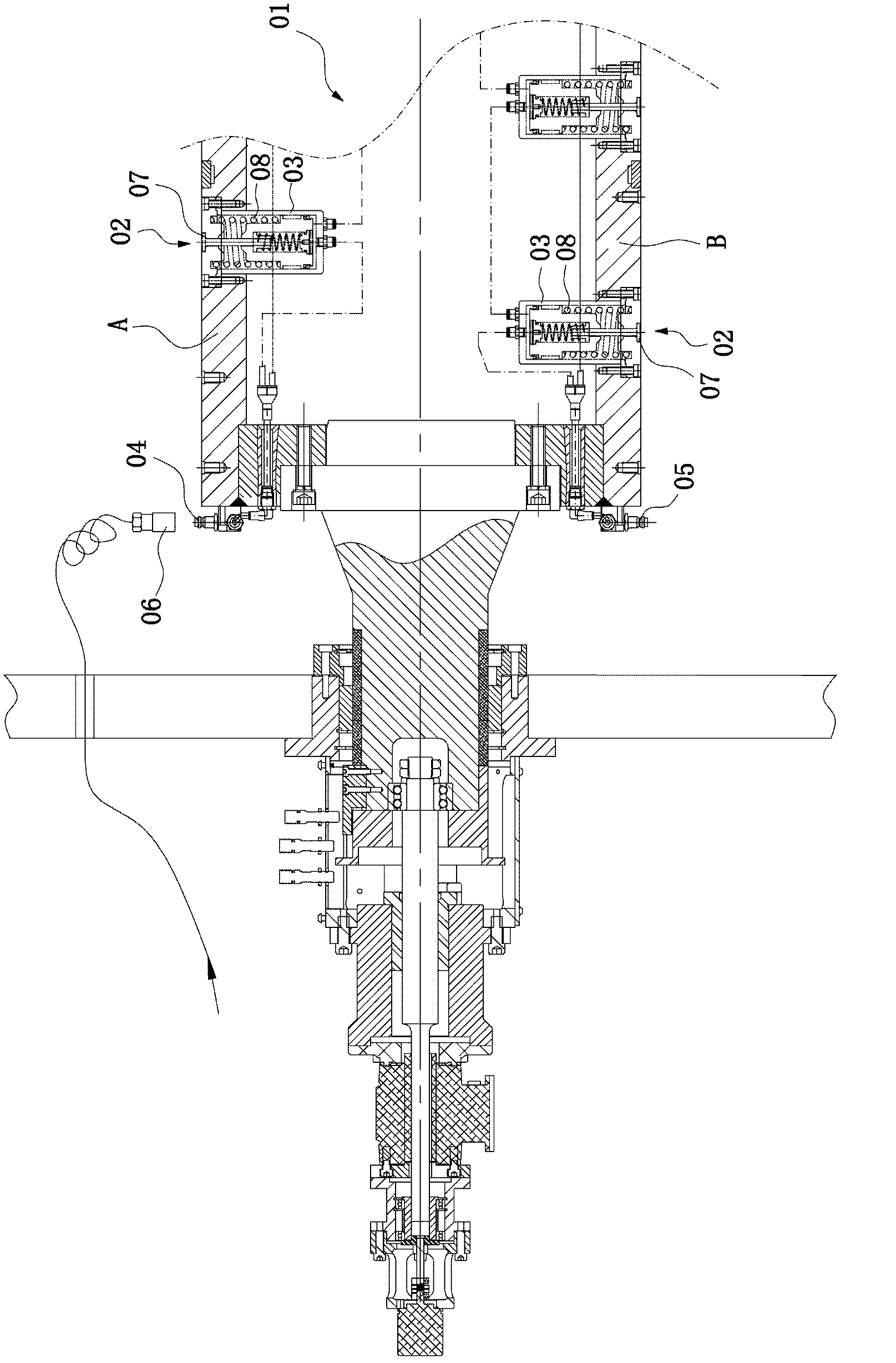

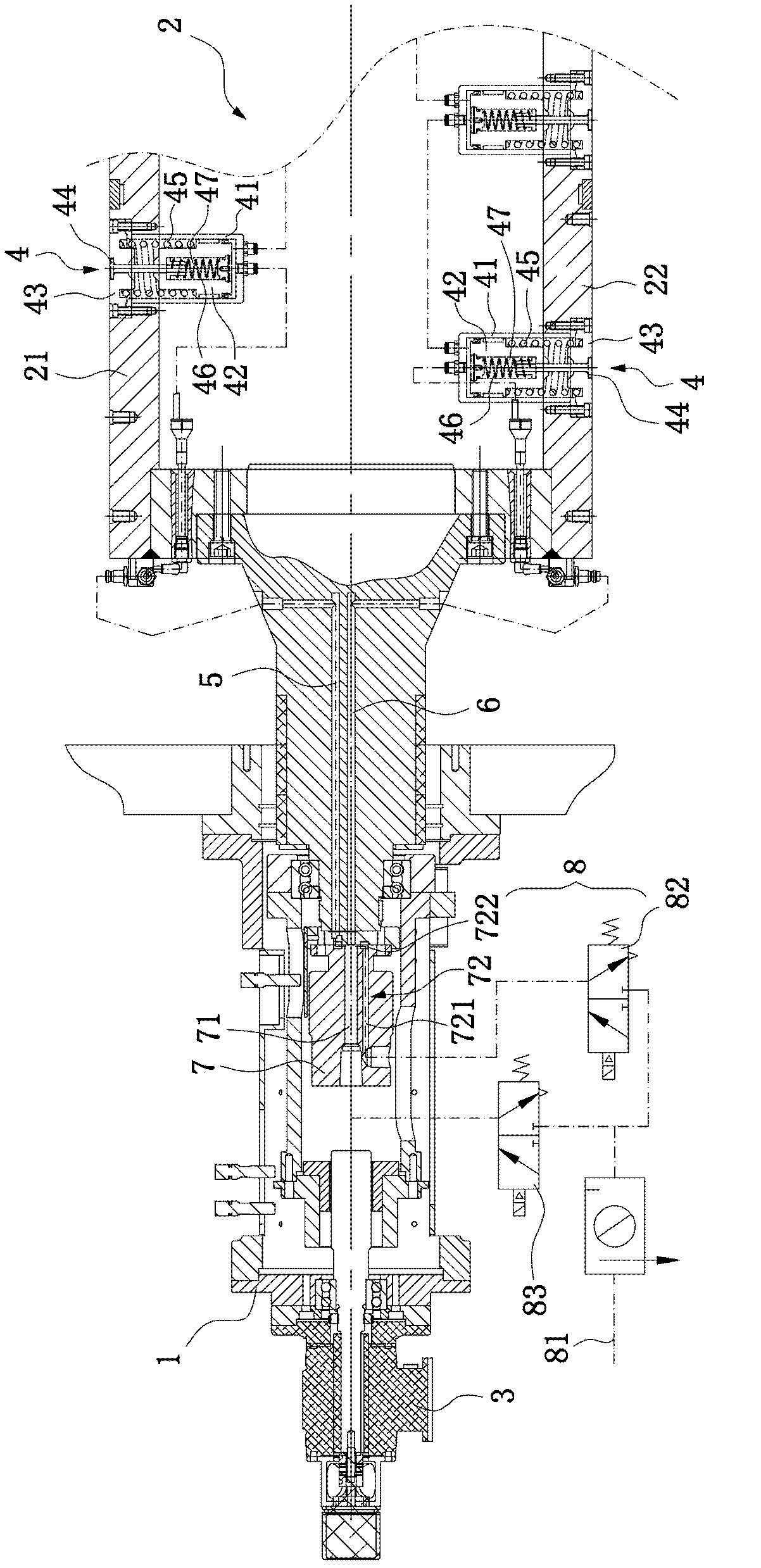

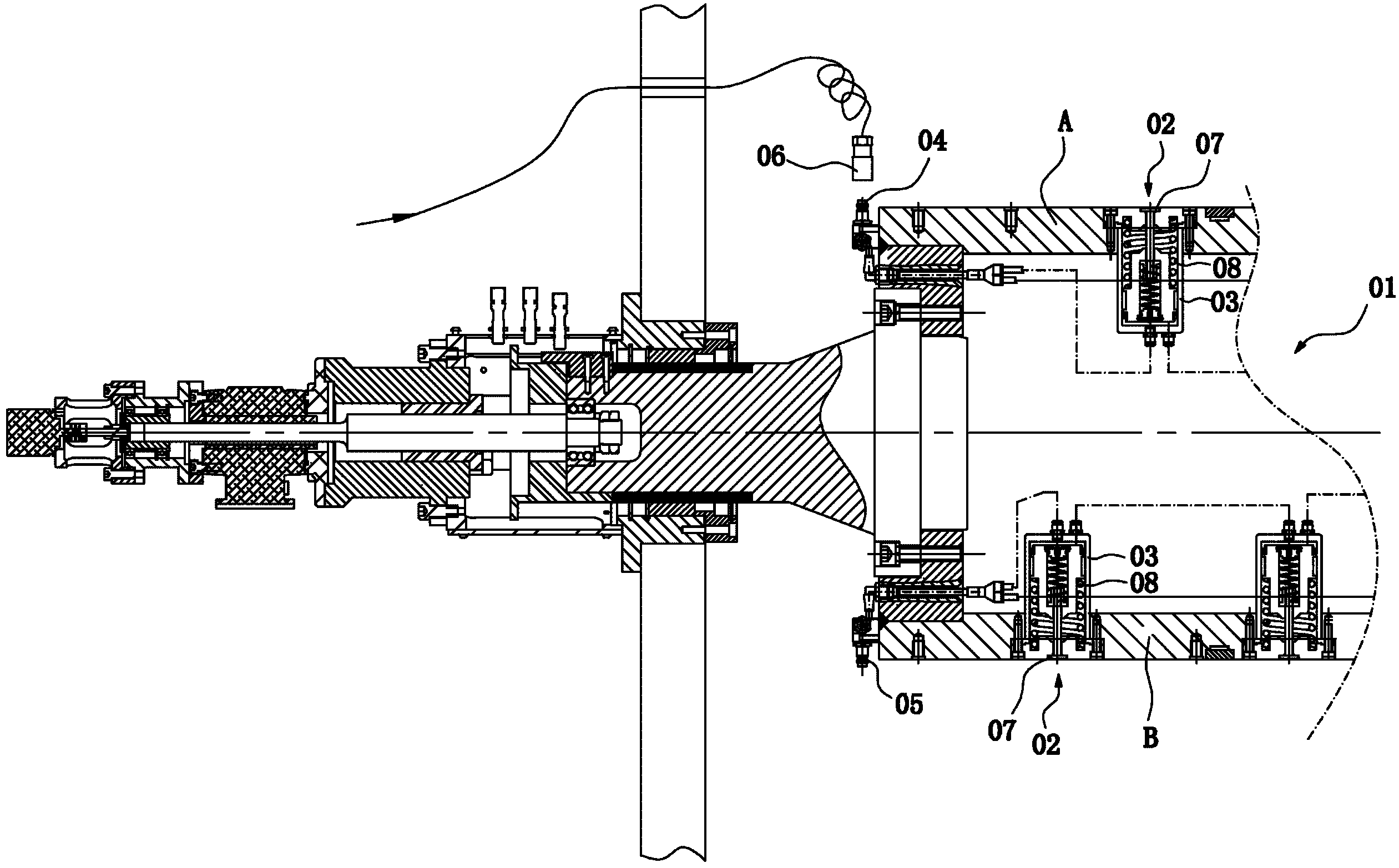

[0010] Below in conjunction with accompanying drawing, the utility patent is further described.

[0011] The die-cutting machine-specific rapid automatic control template locking system of this embodiment includes a wallboard (machine base 1), a template roller body 2, and a device 3 for axially moving the template roller body 2, and two parts of the template roller body 2 The end is installed on the wallboard (base 1) through bearings. The stencil roller body 2 is divided into a first semicircle area 21 and a second semicircle area 22. Each semicircle area is provided with a plurality of pistons for fastening the panel. The inlay unit 4 is provided with two channels at the end of the left shaft head of the stencil roller body 2, the first channel 6 communicates with the bottom of the piston cylinders of all the piston-type inlay units on the first semicircular area 22 of the stencil roller body, The second channel 5 communicates with the piston cylinders of all the piston-typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com