Process for sectionally putting up ship berths or docks

A technology for ships and slipways, applied in slipways, dry docks, ship parts, etc., can solve problems such as reducing construction efficiency, increasing safety hazards, affecting slipway cycles, etc., to reduce construction difficulty, reduce safety hazards, and improve loading efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

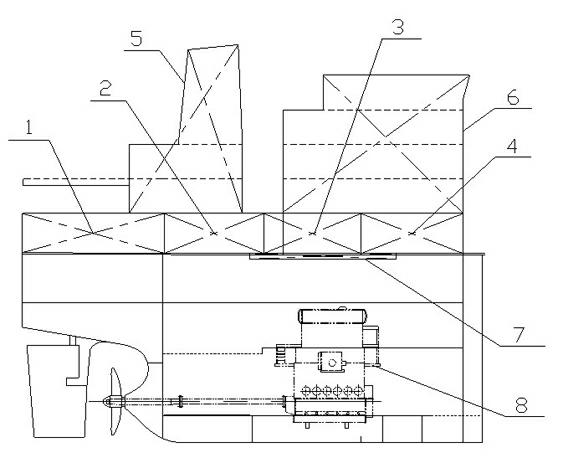

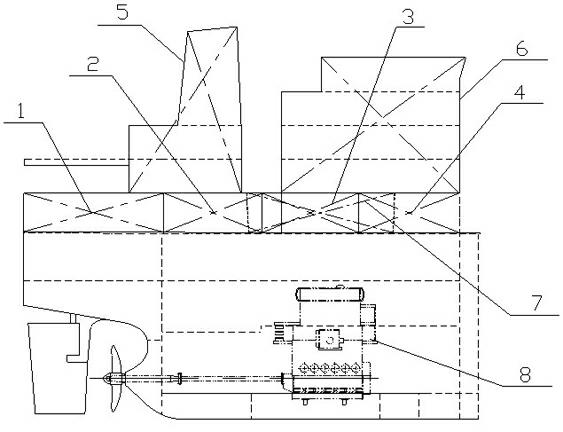

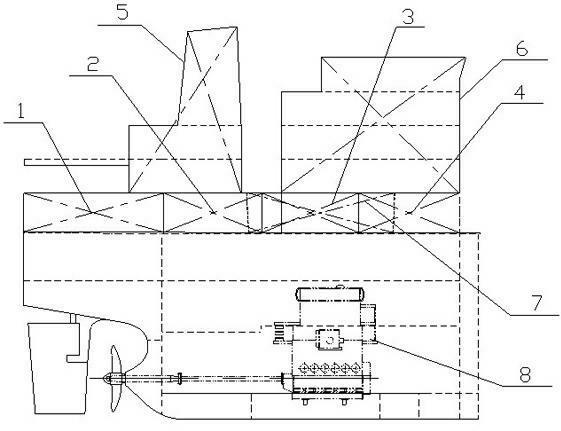

[0019] Such as figure 2 It shows a specific embodiment of the process of loading a ship's berth or dock section in the present invention, including the following steps:

[0020] A. On the berth or dock, the ship’s engine room area, that is, the structure below the main deck, is carried out;

[0021] B. Carry the first general section 1, the second general section 2, the third general section 3, the fourth general section 4, the first general section 1, the second general section 2, the third general section 3 and the fourth general section on the main deck The upper plane formed after the fourth general section 4 is installed is the poop deck, and the fifth general section 5 is installed on the top of the first general section 1 and the second general section 2, and the first general section 1 and the second general section 2. The third general section 3, the fourth general section 4 and the fifth general section 5 are structurally assembled and welded, and at the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com