Storage bottle cover and packaging bottle

A bottle cap and material storage technology, which is applied in the field of material storage bottle caps and packaging bottles, can solve problems such as unreasonable packaging structure, inconvenient use, etc., which cannot meet the market and people's health requirements, and achieve freshness preservation effect, long shelf life, The effect of reducing the use of preservatives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

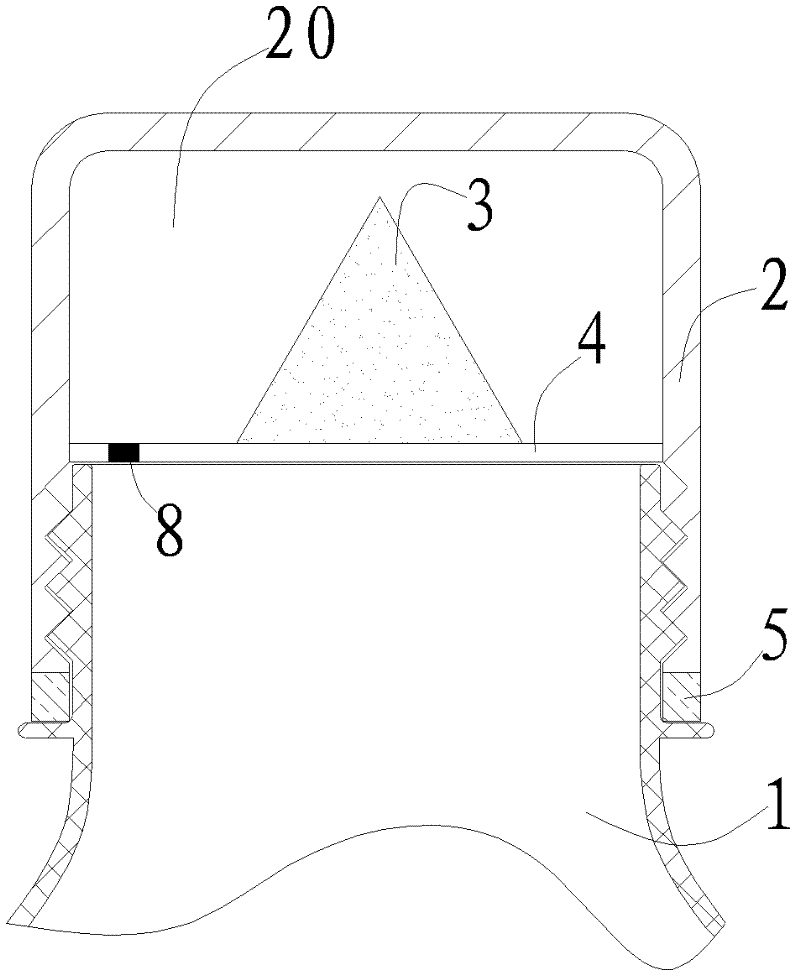

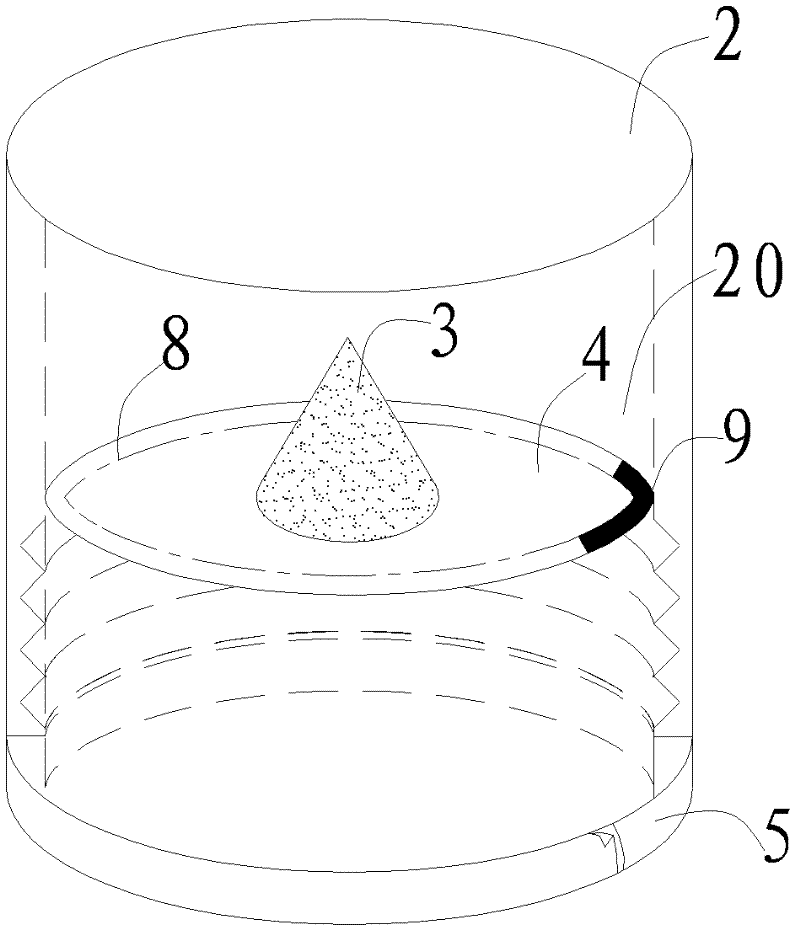

[0023] storage bottle caps, such as figure 1 and figure 2 As shown, a bottle cap body 2 is included, and a diaphragm 4 is arranged inside the bottle cap body 2 to form a sealed material storage space 20 . The storage space 20 is used to store the active ingredient 3 of the beverage concentrate or solid powder. Only when it is used, the diaphragm is pierced to release the active ingredient in the storage space, which can prolong the shelf life and reduce the use of preservatives. To be safer, a weakening line 8 may be provided on the diaphragm 4 to make it easier to release the active ingredient. The diaphragm 4 can be pasted on the inner wall of the bottle cap body 2 . When in use, the bottle cap body 2 can be turned to a certain degree in a tight direction, so that the mouth of the bottle breaks the diaphragm 4, and the active ingredients in the storage space 20 are released. The lower end of the bottle cap body 2 is provided with a safety ring 5 . The active ingredient ...

Embodiment 2

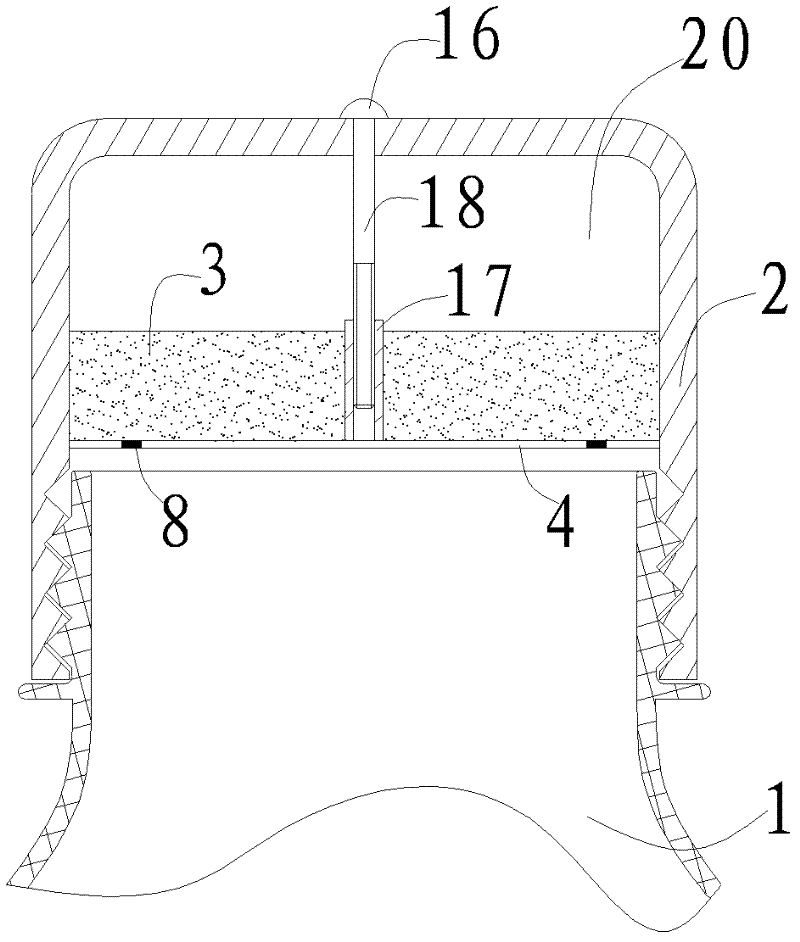

[0025] Such as image 3 and Figure 4 As shown, the diaphragm 4 is fixed on one end of a central axis sleeve 17, the other end of the central axis sleeve 17 is provided with a threaded hole, and one end of a screw 16 is placed in the threaded hole and connected with the central axis sleeve 17 is threaded, and the other end stretches out from the top of the bottle cap body 2, and is threadedly connected with the bottle cap body 2. One end of the screw rod 16 exposed on the top of the bottle cap body is provided with an opening device such as a cross groove or a slot. By rotating the screw 16, the membrane 4 is pulled upwards to tear the membrane, thereby releasing the active ingredient 3 in the material storage space 20 .

Embodiment 3

[0027] Such as Figure 5 As shown, the bottle cap body 2 is provided with a pull-out mouth 6, and a connecting rod 11 is arranged in the pull-out mouth 6 to connect with the diaphragm 4, and the pull-out mouth 6 is pulled upward or rotated to tear the pull-out mouth 6. Cleave the membrane 4 to release the active ingredient 2. Two limiting grooves 13 are arranged inside the bottle cap body 2 . The mouthpiece 6 is placed in the bottle cap body 2, the bottom of which is an elastic limit ring 12, and the limit ring 12 can be stuck in the limit groove 13 in the bottle cap body 2 to prevent the mouthpiece 6 from breaking away from the bottle. Cover 2. When in use, the mouthpiece 6 is pulled out, the connecting rod 11 tears the diaphragm 4, and the active ingredient 3 enters the bottle from the rupture. In addition, this solution can open the mouth 10 on the mouthpiece 6 and avoid the problem of unscrewing the bottle cap to drink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com