Multifunctional flocculation and oscillation experiment device

An experimental device and multi-functional technology, applied in the field of water treatment, can solve the problems of limiting water purification effect, occupying a large space, fixed internal structure, etc., to achieve the effect of improving water purification effect, reducing occupied space, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

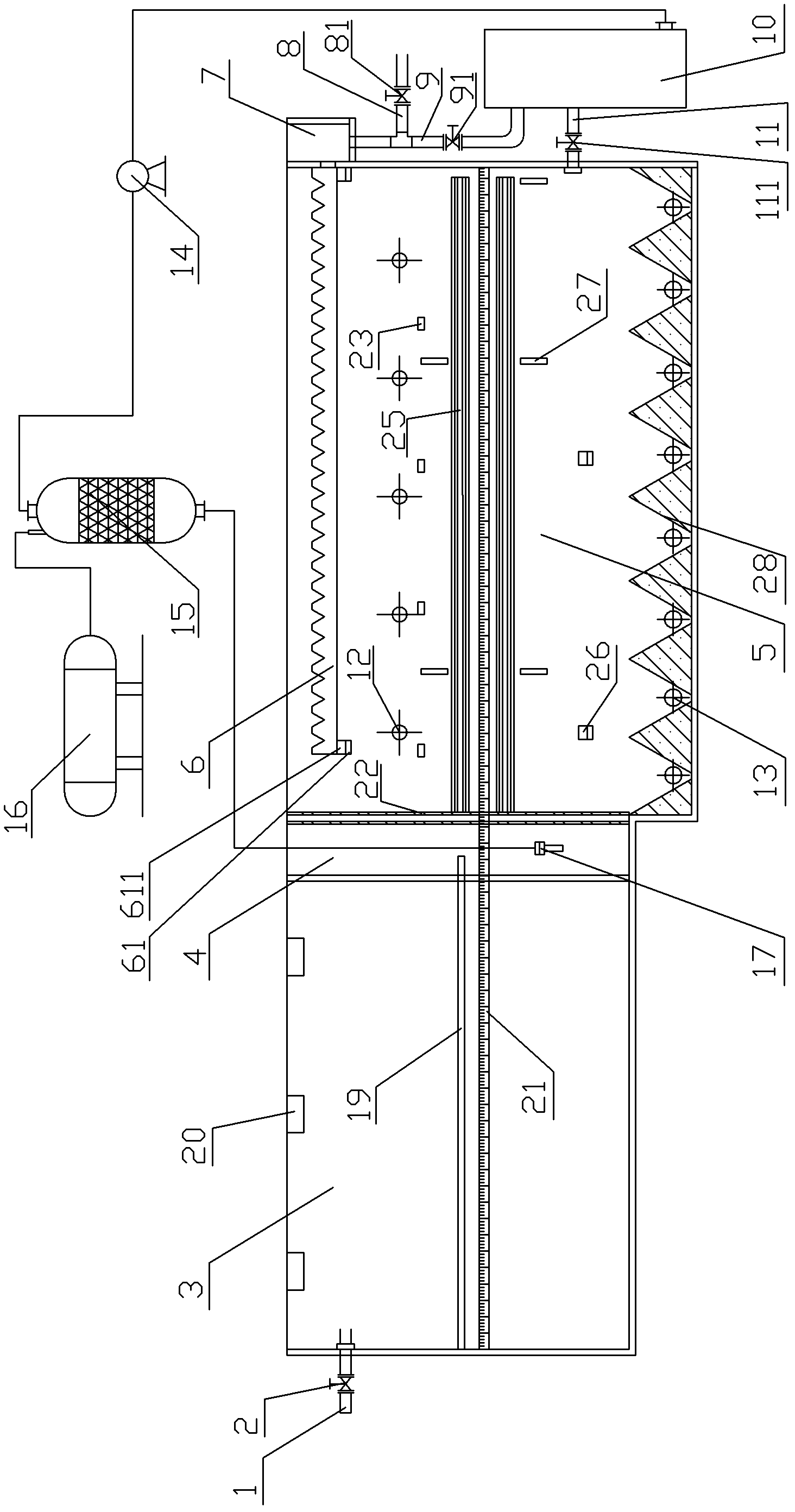

[0049] Example 1: The flocculation and sinking experimental device composed of the reciprocating partition flocculation tank and the upward flow inclined plate floating and sinking tank, see Figure 1-6 :

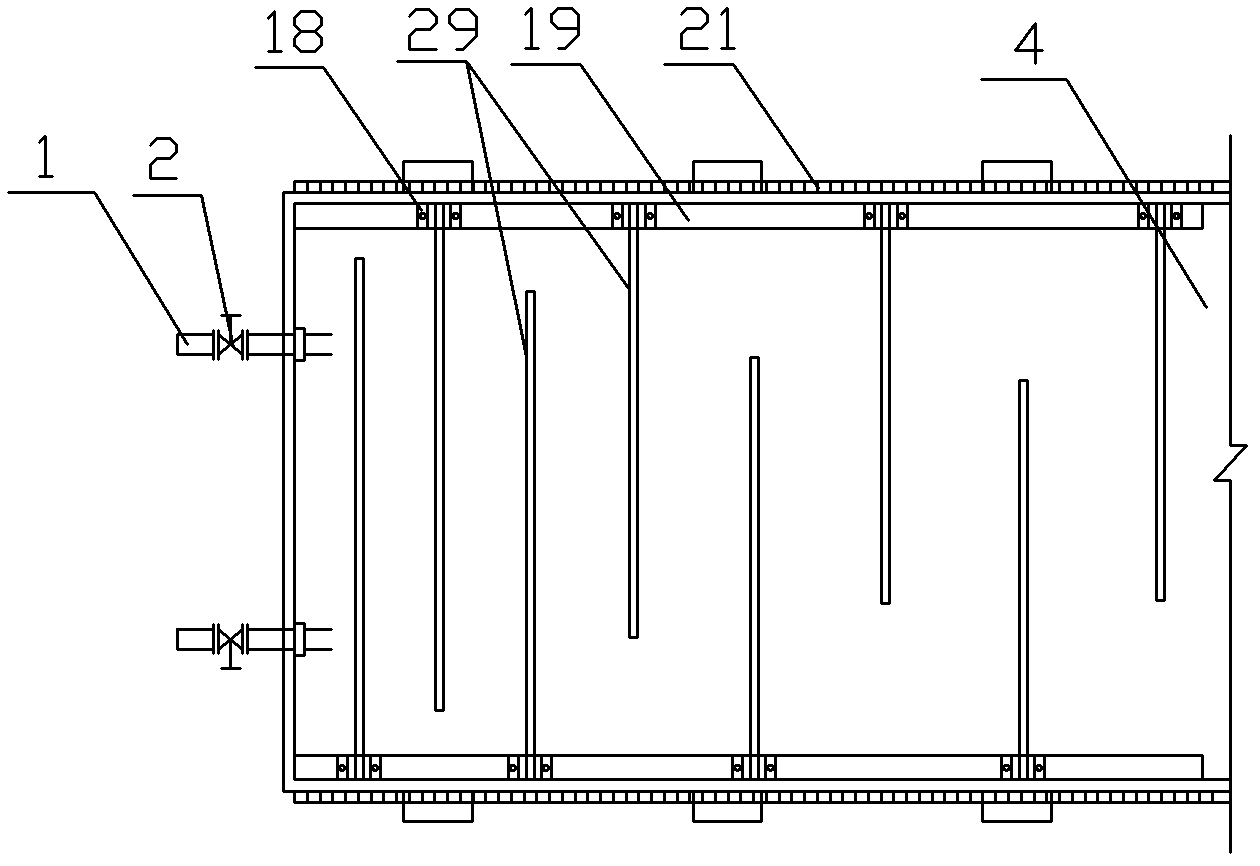

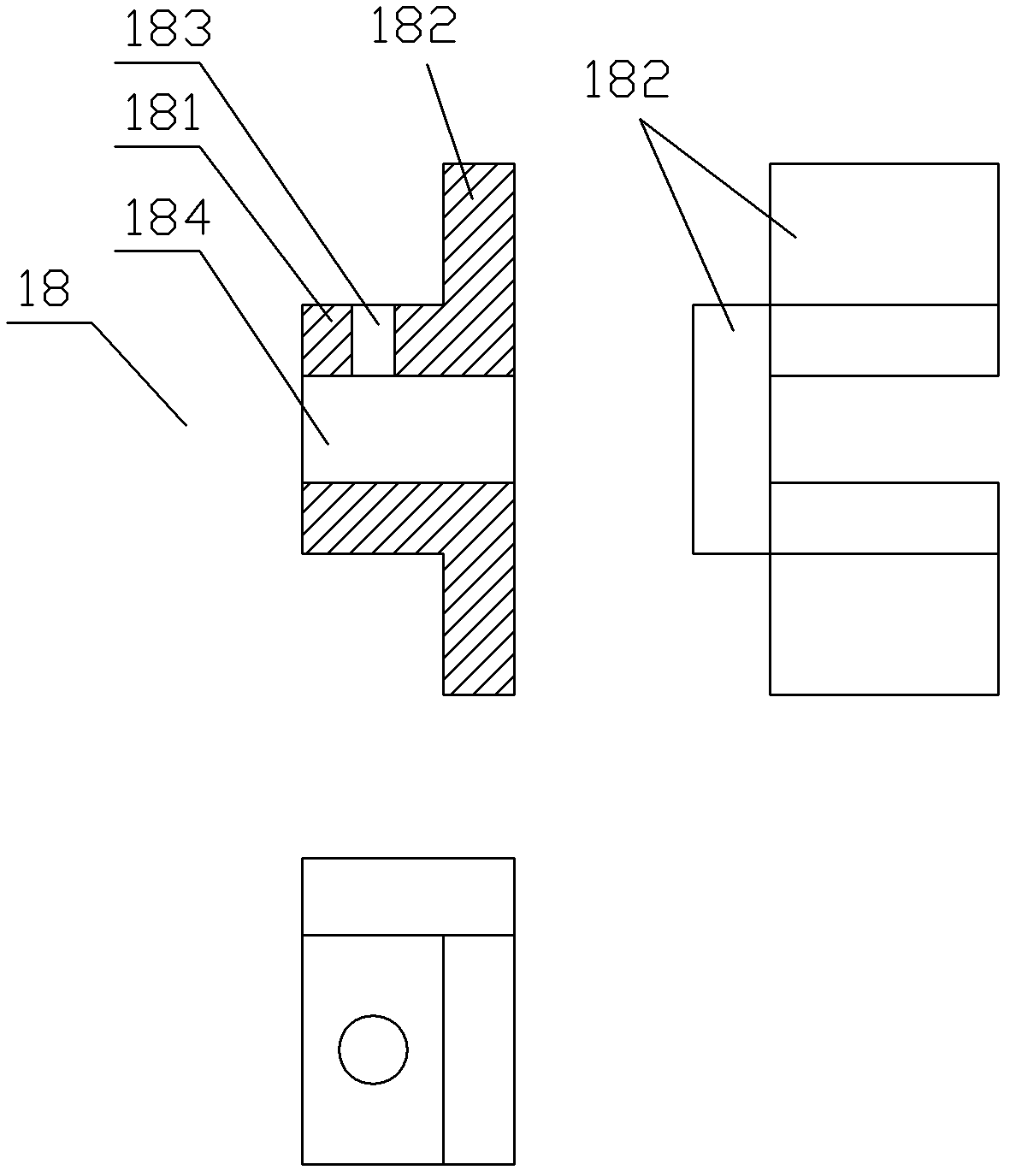

[0050] The reciprocating partition flocculation tank is selected as the flocculation tank. Several partitions 29 with grooves are arranged in the reciprocating partition flocculation tank. The distance between the partitions 29 is selected according to the requirements of the experimental design parameters, and the scale 21 is used to determine the distance between the partitions 29. At the position in the flocculation tank 3, the slide plate 19 is embedded in the groove of the partition plate 29, and each partition plate 29 is clamped by two baffle plate holders 18, and the screws in the screw holes 183 are tightened; Inclined plate floating sink, the floating sink is divided into mud accumulation section 38, water distribution section 39, inclined plate section 40, gas co...

example 2

[0052] Example 2: The flocculation and sinking experimental device composed of the combined flocculation tank of folded plate and flat plate and the upward flow inclined plate floating and sinking tank, see figure 1 , 3 -7:

[0053] The flocculation tank in Example 1 is changed to the combined flocculation tank of the folded plate and flat plate, and the others remain unchanged. The combined flocculation tank of the folded plate and flat plate is divided into different bands 31, 32 of the same band and flat plate 33 by several partitions 34, 31 of different bands and the same band. 32 are provided with a number of folded plates 30, the peaks of the folded plates 30 in different bands 31 are arranged oppositely, and the peaks of the folded plates 30 in the same band 32 are arranged in parallel to the troughs, and a number of flat plates 35 are arranged in the flat plate section 33, selected according to the requirements of the experimental design parameters. Decide the distanc...

example 3

[0055] Example 3: The flocculation-flotation-sinking experimental device composed of a mechanical flocculation tank and an upward-flowing inclined plate floating-sinking tank, see figure 1 , 3 -6, 8:

[0056] The flocculation tank in Example 1 is replaced by a mechanical flocculation tank, and the others remain unchanged. The mechanical flocculation tank is divided into 2 groups by a plurality of partitions 341, each group is divided into 3 grids, and a set of stirring equipment 36 is arranged in each grid, and the stirring equipment 36 is inserted into The support 37 in the clamping groove 20 is fixed, the distance between the partitions 341 is selected according to the requirements of the experimental design parameters, the position of each partition 341 in the flocculation tank 3 is determined by the scale 21, and the slide plate 19 is embedded in the recess of each partition. At the slot, each partition 341 is clamped by two holders 18, and the screws in the screw holes 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com