Wiredrawing automatic ending control system based on programmable logic controller and control method thereof

A technology of programming controller and control system, used in manufacturing tools, glass manufacturing equipment, etc., to reduce human judgment and workload, improve wire drawing work efficiency, and achieve the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

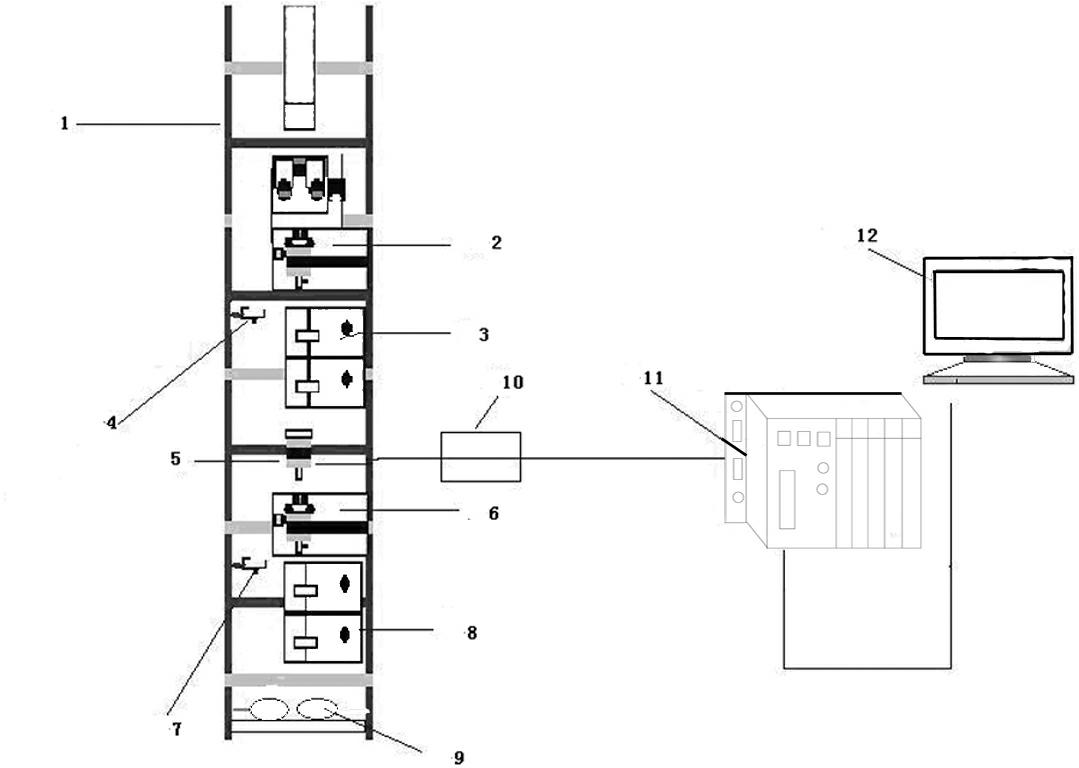

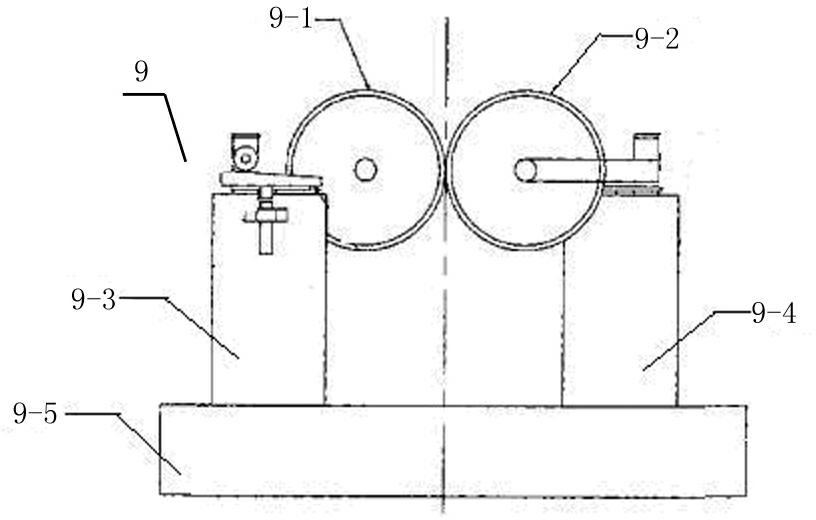

[0022] Refer to attached Figure 1~4 , The drawing automatic finishing control system based on programmable controller includes on-line detection of optical fiber defect device, automatic cutting of optical fiber and coating device, polarizing film dispersion (PMD) twisting automatic pop-up device, programmable logic controller (PLC), host computer .

[0023] The device for online detection of optical fiber defects includes an optical fiber measuring probe 5 and a signal processor 10. The optical fiber measuring probe 5 is installed on the drawing tower 1 at the lower part of the optical fiber coating and curing furnace 3. The optical fiber passes through the detection hole of the optical fiber measuring probe, and the optical fiber measuring probe 5 passes the signal. The communication line is connected with the signal processor 10 .

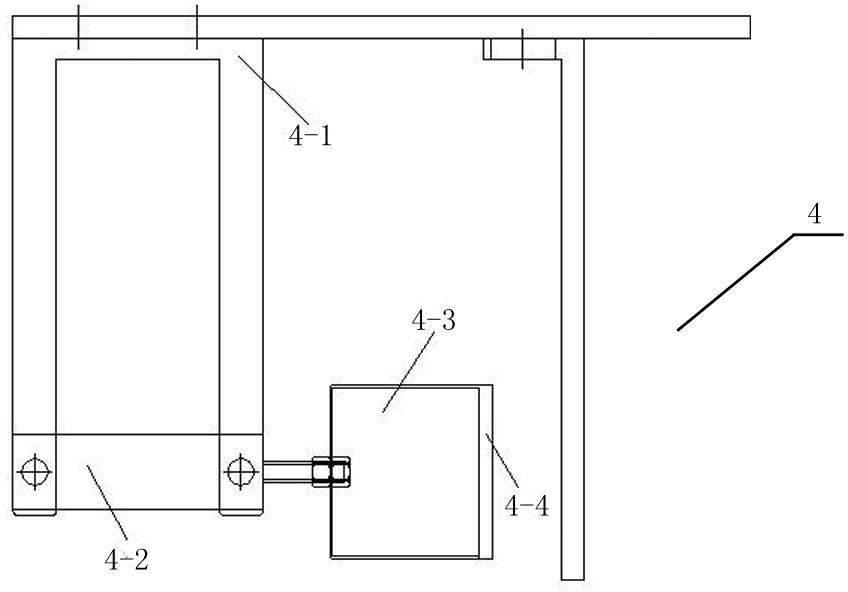

[0024] There are two sets of automatic fiber cutting and coating connection devices, respectively, the first automatic fiber cutting and coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com