Method for preparing cordierite ceramics by using serpentine tailings

A technology of serpentine tailings and cordierite, which is applied to the removal of solid waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

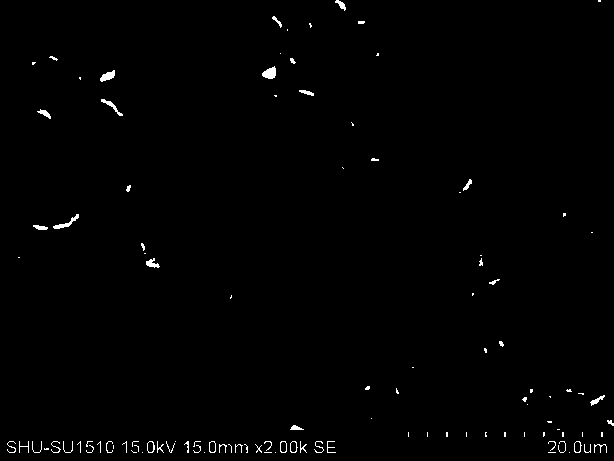

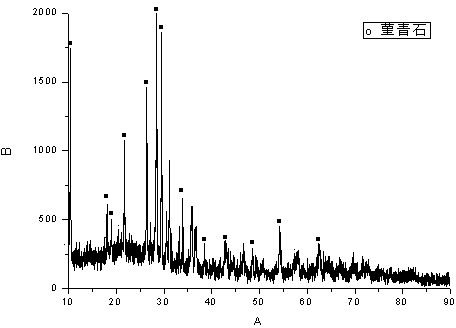

[0041] Example 1: The dried serpentine tailings and kaolin tailings are then turned in a ball mill at 300r / min for 1 hour according to the ratio of serpentine tailings 35% kaolin tailings 60% alumina 5%. Then take out the powder, grind it with a ball mill and a mortar and pass it through 100 mesh. Take the sieved powder, add 10% PVA solution (5% concentration), mix again, and pass through a 30-mesh sieve. Put the above-mentioned mixed powder into a stainless steel mold, and apply a pressure of 10MPa to shape the material. Then put it into a high-temperature furnace, and the heating rate is controlled at 60 oC / h; at 800 oC Keep warm for 0.5h, then control the heating rate at 200 oC / h, raised to 1300°C for 2h. Cool naturally to obtain cordierite ceramics. The SEM and XRD figures of the sample obtained in this embodiment are shown in figure 1 with figure 2 .

Embodiment 2

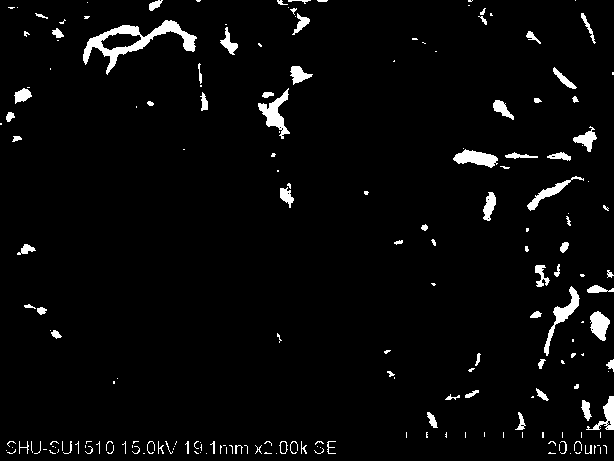

[0042] Example 2: The dried serpentine tailings and kaolin tailings are then turned in a ball mill at 200r / min for 2 hours according to the ratio of serpentine tailings 30% kaolin tailings 60% alumina 10%. Then take out the powder, grind it with a ball mill and a mortar and pass it through 100 mesh. Take the sieved powder, add 8% PVA solution (5% concentration), mix evenly again, and pass through a 30-mesh sieve. Put the above-mentioned mixed powder into a stainless steel mold, and apply a pressure of 8MPa to shape the material. Then put it into a high-temperature furnace, and the heating rate is controlled at 100 oC / h; at 800 oC Keep warm for 1h, then control the heating rate at 200 oC / h, raised to 1200°C for 2h. Cool naturally to obtain cordierite ceramics. The SEM and XRD figures of the sample obtained in this embodiment are shown in image 3 with Figure 4 .

Embodiment 3

[0043] Example 3:The dried serpentine tailings and kaolin tailings are then turned in a ball mill at 300r / min for 1 hour according to the ratio of serpentine tailings 25% kaolin tailings 70% alumina 5%. Then take out the powder, grind it with a ball mill and a mortar and pass it through 100 mesh. Take the sieved powder, add 9% PVA solution (5% concentration), mix evenly again, and pass through a 30-mesh sieve. Put the above-mentioned mixed powder into a stainless steel mold, and apply a pressure of 10MPa to shape the material. Then put it into a high-temperature furnace, and the heating rate is controlled at 80 oC / h; at 800 oC Keep warm for 1h, then control the heating rate at 250 oC / h, raised to 1300°C for 2h. Cool naturally to obtain cordierite ceramics. The SEM and XRD figures of the sample obtained in this embodiment are shown in Figure 5 with Image 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com