Extracting method and extracting device for high purity aluminum

An extraction method and high-purity technology, which is applied in the production of refined aluminum products with a purity above 3N, can solve the problems of complicated operation process and difficult control of pure aluminum crystallization, and achieve good separation effect, energy saving and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

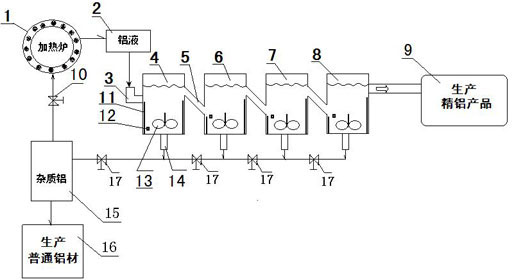

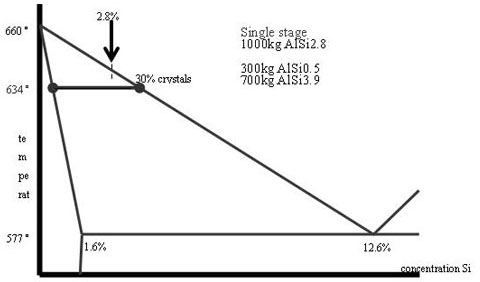

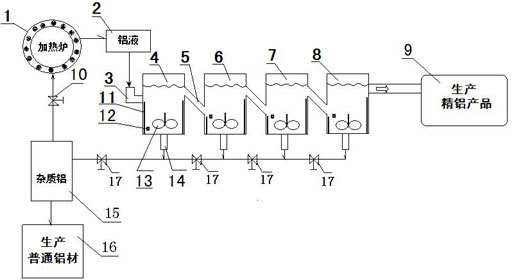

[0046] Put the molten aluminum ingot containing Si, Fe, Cu, Pb, Zn, Ca, Ti, Cd, Ag, In and other elements into the vacuum heater and heat it to 690-700°C to obtain aluminum liquid, which contains the injection level In the middle of the crystallizer, crystallization occurs at a temperature of 670°C-680°C. After crystallization, the pure aluminum settles in the lower part of the primary crystallizer due to its high density. The temperature of the molten aluminum with impurities above the crystallizer is still above the melting point, floating above the primary crystallizer, and sent to the secondary crystallizer to continue crystallization, the same crystallized pure aluminum settles in the lower part of the secondary crystallizer, and the aluminum liquid containing impurities floats above the secondary crystallizer, and Sent to the three-stage crystallizer, through the three-stage or four-stage crystallizer, the aluminum liquid containing more impurities is sent to the impurity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com