Split mounting type heat-insulation and waterproof roof structure

A waterproof structure, assembled technology, applied in the direction of roof, roof covering, roof using tile/slate tile, etc., can solve the problems of low construction efficiency, high engineering cost, low strength, etc., to achieve long structural life, no environment. The effect of pollution and low engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

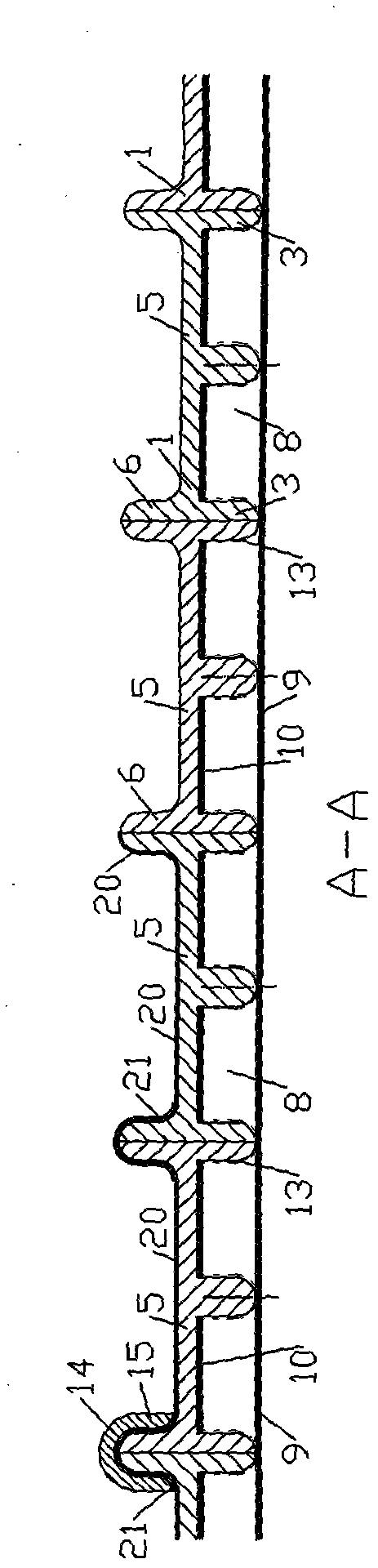

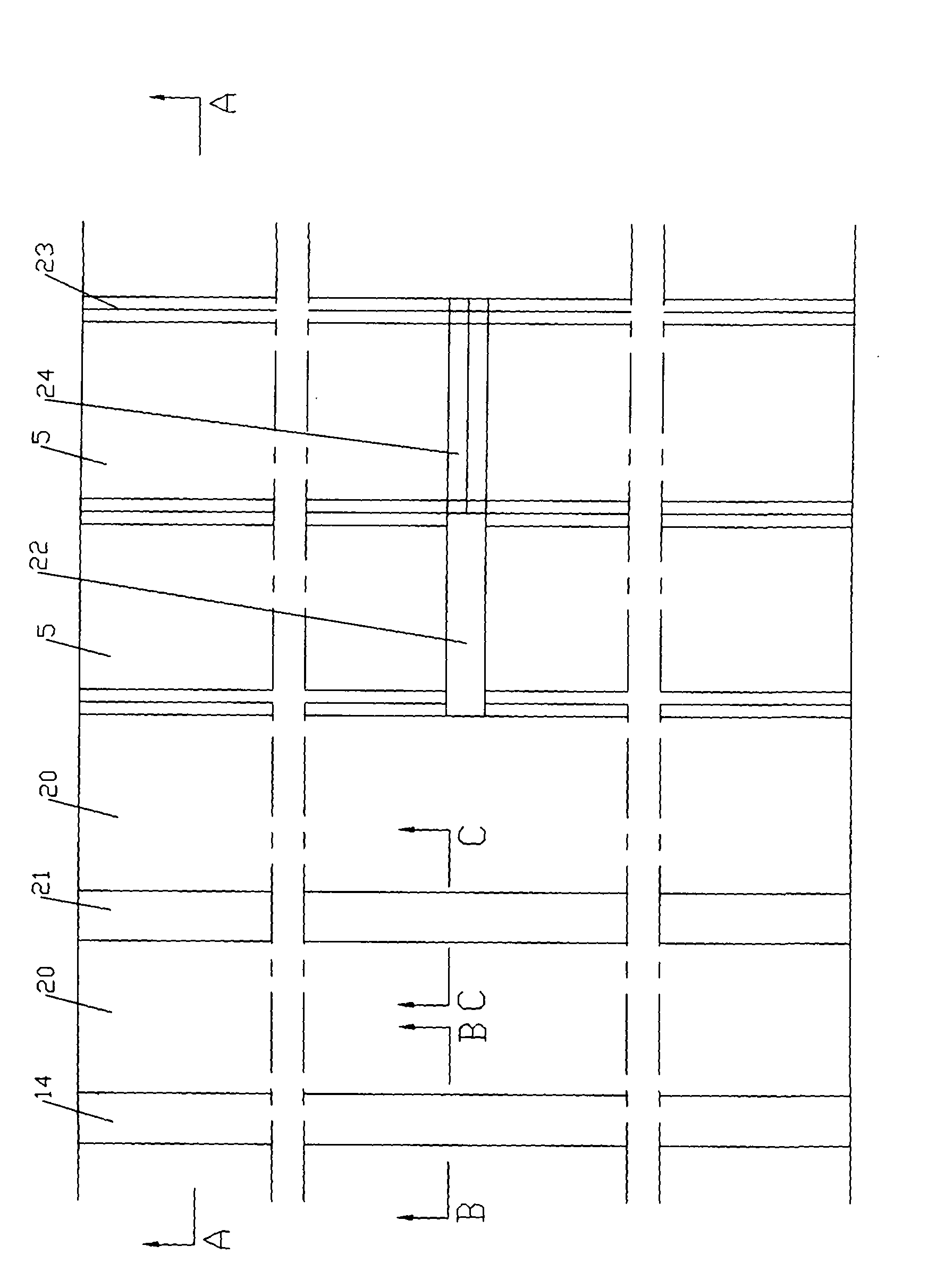

[0039] Such as figure 1 , figure 2 As shown, an assembled roof insulation and waterproof structure of the present invention includes a roof insulation hollow board 1 and a roof waterproof system, as well as on-site assembly of the roof insulation hollow board 1 and laying of waterproof materials.

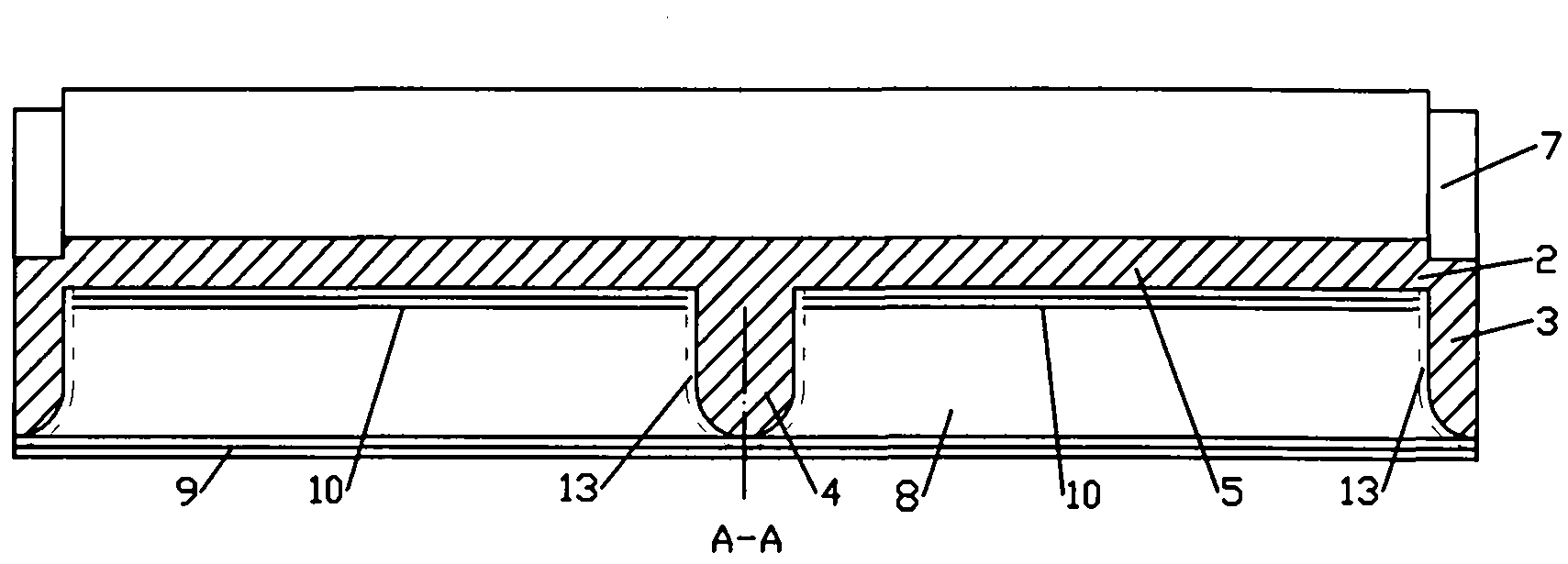

[0040] Such as image 3 , Figure 4 and Figure 5 As shown, the roof insulation hollow panel 1 of the present invention is composed of the roof insulation hollow panel skeleton 2 and the airtight air layer 8 of the roof insulation hollow panel.

[0041] Such as Figure 6 , Figure 7 and Figure 8 As shown, a roof insulation hollow slab skeleton 2 of the present invention is composed of the bottom frame 3 of the insulation hollow slab skeleton, the support rib 4 of the insulation hollow slab skeleton, the panel 5 of the insulation hollow slab skeleton, the half ridge boards 6 on both sides of the insulation hollow slab skeleton, and the insulation Hollow slab skeleton and hal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com