Wall-mounted cantilever scaffold

A cantilevered scaffolding and wall-mounted technology, which is applied in the field of cantilevered beam scaffolding, can solve the problems of wall leakage, large process holes, and hidden dangers of wall leakage, etc., and achieves strong load-bearing capacity, less construction materials, and energy saving The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and examples.

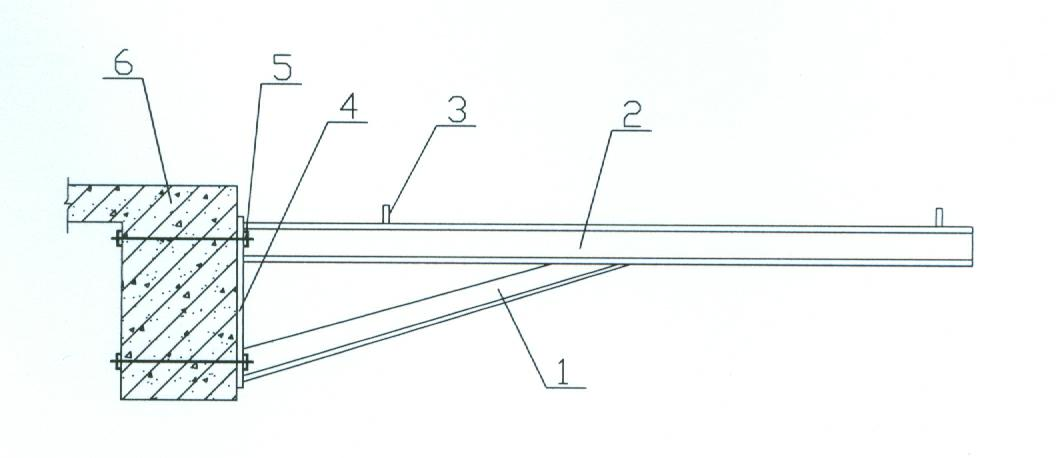

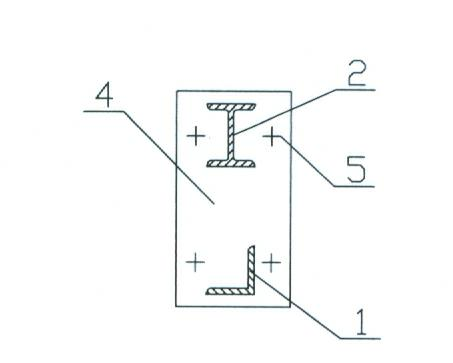

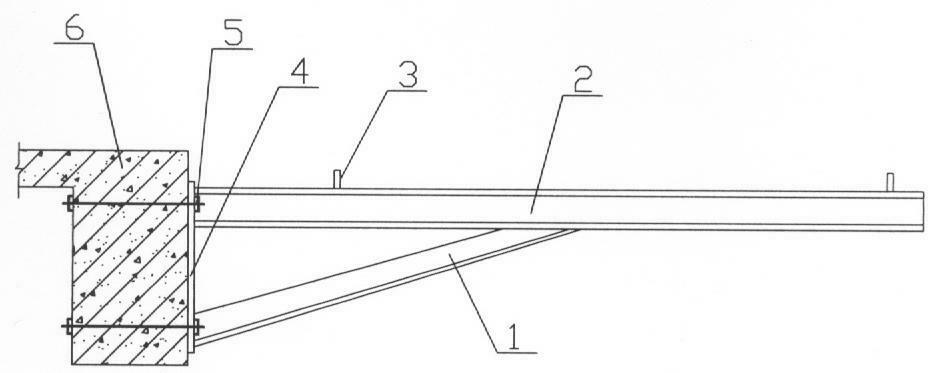

[0016] attached figure 1 The shown wall-mounted cantilevered scaffolding consists of bolts 5 passing through the beam body 6 and a frame body. The frame body is a right-angled triangle frame, and its right-angled side facing the outside of the beam body 6 is a rectangular connecting plate 4, and the four corners of the connecting plate 4 are provided with through holes for installing bolts 5. The upper end of the connecting plate 4 is fixedly connected with the crossbeam 2 at right angles, and one end of the inclined beam 1 which is inclined horizontally is fixedly connected with the middle section of the bottom surface of the crossbeam 2, and the other end is fixedly connected with the lower end of the connecting plate 4. The angle between inclined beam 1 and beam 2 is 15 0 ~25 0 . In the present invention, the crossbeam 2 adopts I-shaped steel, and the I-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com