Construction method of pouring sand-aerated heat-insulating material into steel-structure box type column-beam

A technology of thermal insulation materials and box-shaped column beams, applied in thermal insulation, processing of building materials, building components, etc., can solve problems such as no good solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

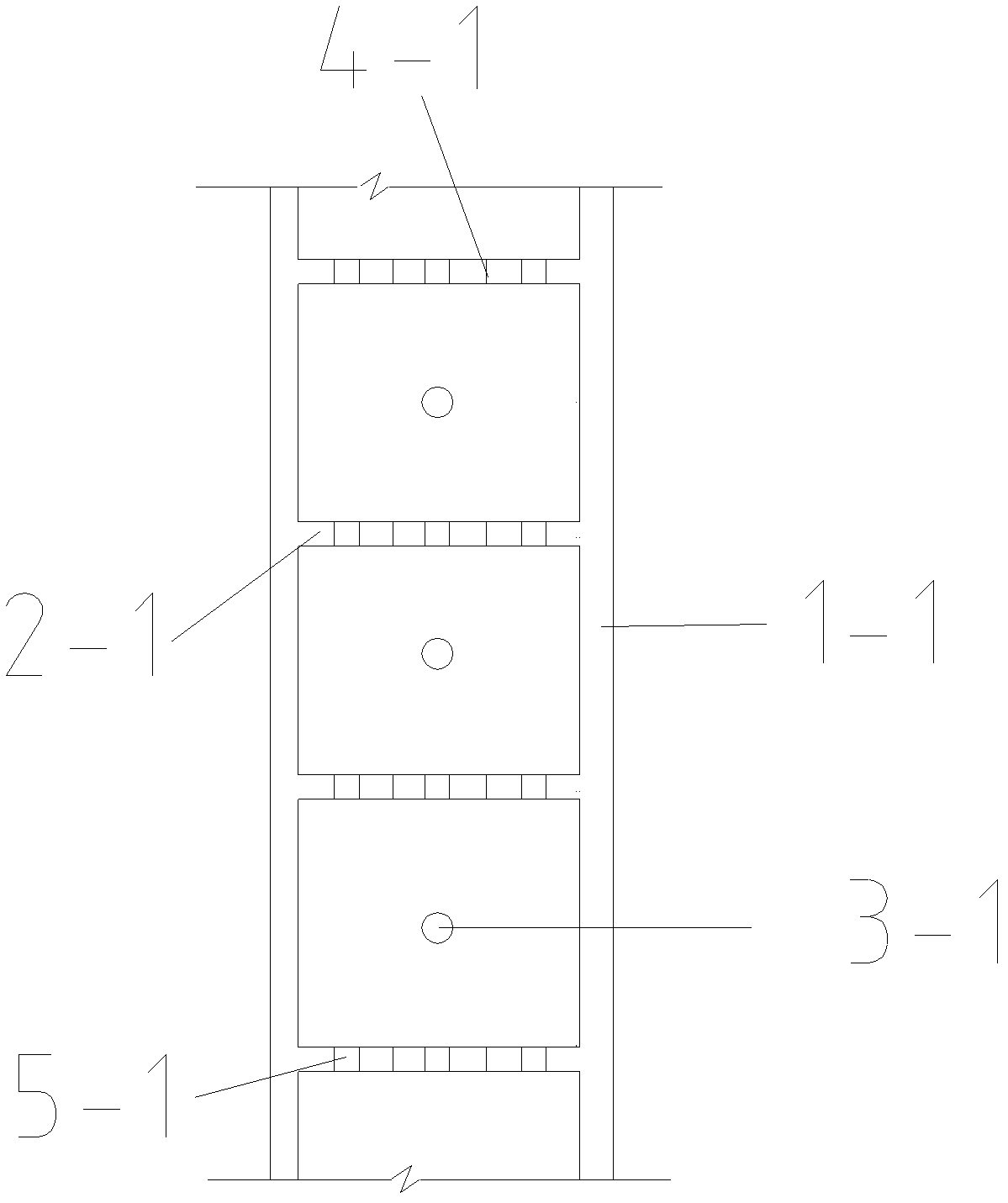

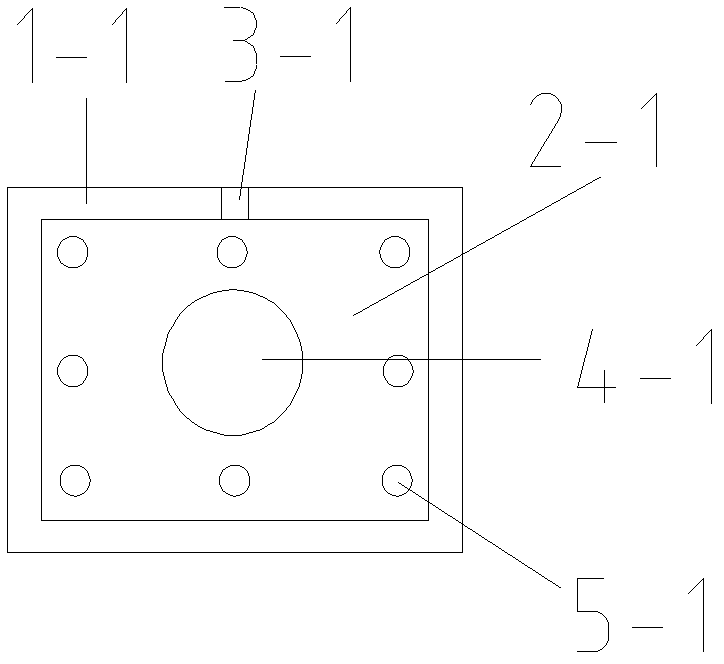

[0019] (1) A plurality of spaced diaphragms 2-1 are installed in the steel column 1-1 to form a plurality of compartments, and flow holes 4-1 are opened on each of the diaphragms; (2) through each A pouring hole 3-1 with a diameter of 4 cm on the side wall of the compartment pours the sand aerated thermal insulation material into the steel column, and the sand aerated thermal insulation material poured into the steel column passes through the middle flow hole on the diaphragm 2-1 4-1 and 8 side flow holes for reflow; the hole diameter of the middle flow hole is 18 cm, and the hole diameter of each side flow hole is 4 cm; The insulation material is used until the insulation material expands to fill each compartment of the steel column beam. After the strength and volume of the poured insulation material reach the specified level, it is hoisted for steel column installation in the steel structure.

[0020] After use: there is no cold bridge problem in the box-shaped steel column...

Embodiment 2

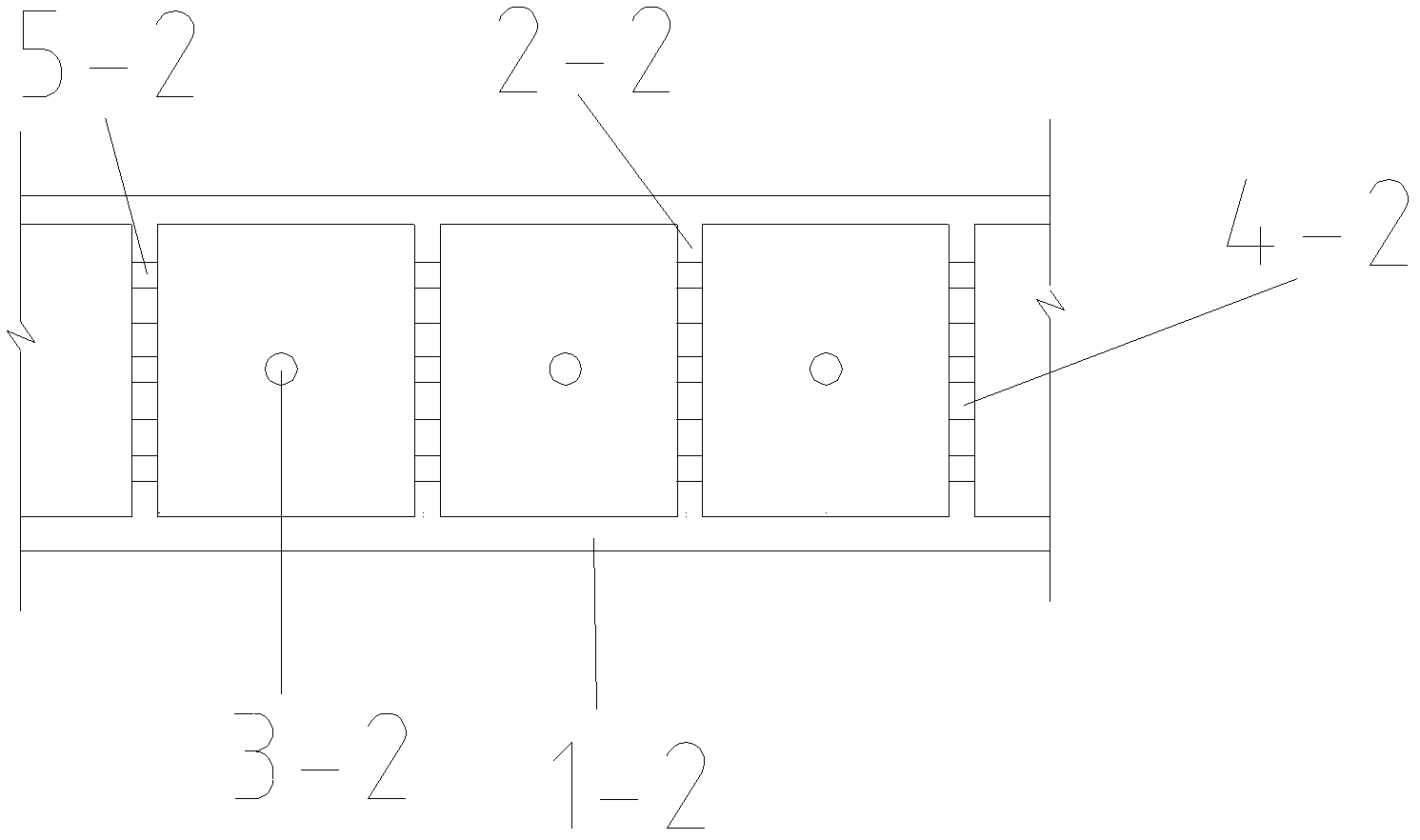

[0022] (1) install a plurality of transverse diaphragms 2-2 arranged at intervals in the steel beam 1-2 to form a plurality of compartments, and open flow holes 4-2 on each of the transverse diaphragms; (2) through each A filling hole 3-2 with a diameter of 8 cm on the side wall of a compartment (that is, the side wall of the steel column beam) pours the sand aerated thermal insulation material into the steel column beam, and the sand aerated thermal insulation material poured into the steel column beam passes through The middle flow hole 4-2 on the diaphragm 2-2 reflows; and the 6 side flow holes reflow; the hole diameter of the middle flow hole is 25 cm, and the hole diameter of each side flow hole is 6 cm; (3) After filling the sand-entrained thermal insulation material, maintain the thermal insulation material until the thermal insulation material expands to fill each compartment of the steel column beam. After the strength and volume of the perfused thermal insulation mate...

Embodiment 3

[0025] (1) install a plurality of transverse diaphragms 2-2 arranged at intervals in the steel beam 1-2 to form a plurality of compartments, and open flow holes 4-2 on each of the transverse diaphragms; (2) through each A pouring hole 3-2 with a diameter of 6 cm on the side wall of a compartment (that is, the side wall of the steel column beam) pours the sand aerated thermal insulation material into the steel column beam, and the sand aerated thermal insulation material poured into the steel column beam passes through The middle flow hole 4-2 on the diaphragm 2-2 reflows; and the 6 side flow holes reflow; the hole diameter of the middle flow hole is 22 cm, and the hole diameter of each side flow hole is 5 cm; (3) After filling the sand-entrained thermal insulation material, maintain the thermal insulation material until the thermal insulation material expands to fill each compartment of the steel column beam. After the strength and volume of the perfused thermal insulation mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com