Full-closed auxiliary frame for energy-saving building doors and windows

A building energy-saving and fully enclosed technology, applied in the direction of window/door frame, frame fixing, etc., can solve problems such as corrosion, leakage, cost, etc., and achieve the effects of shortening cold bridges, convenient installation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

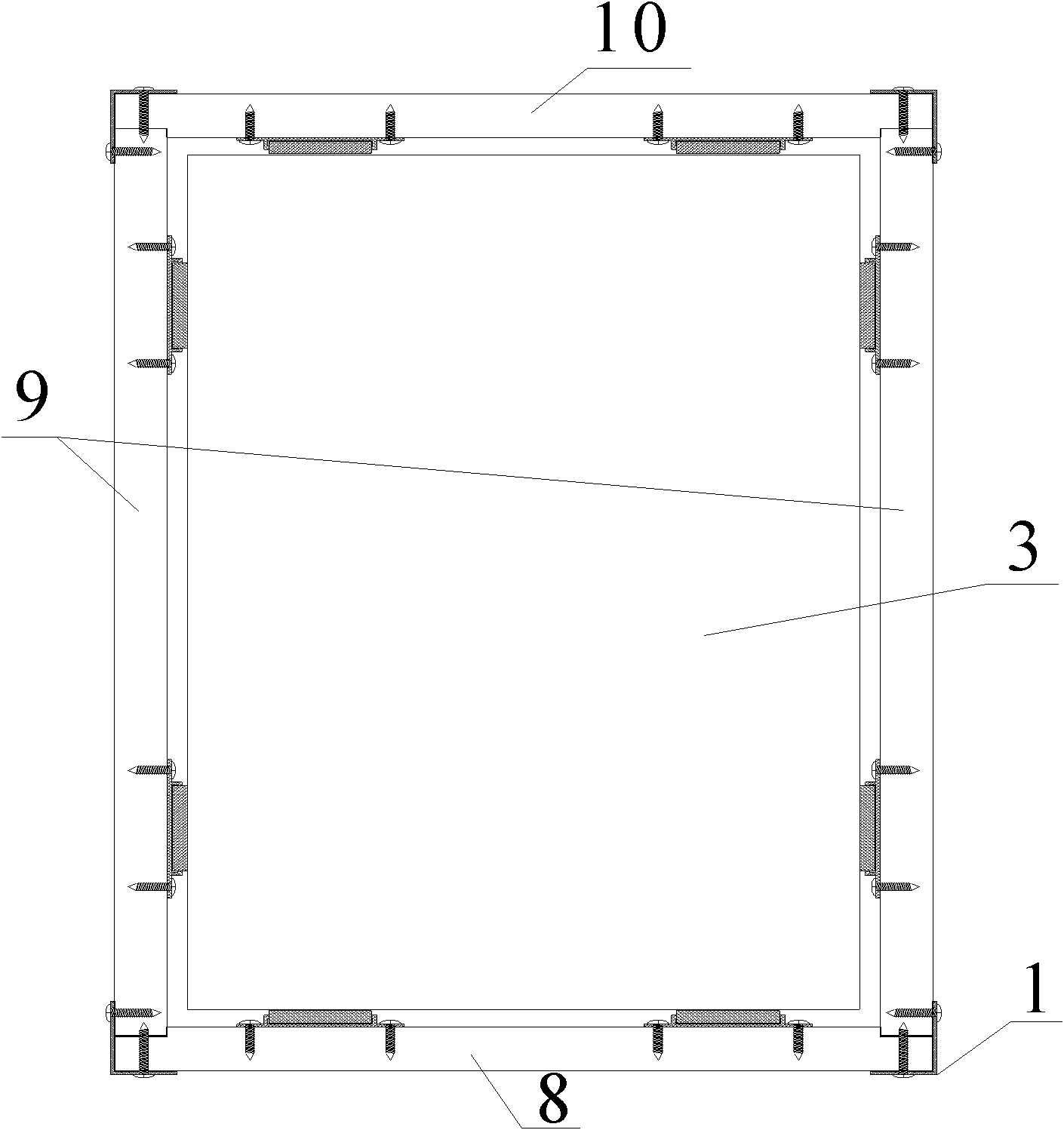

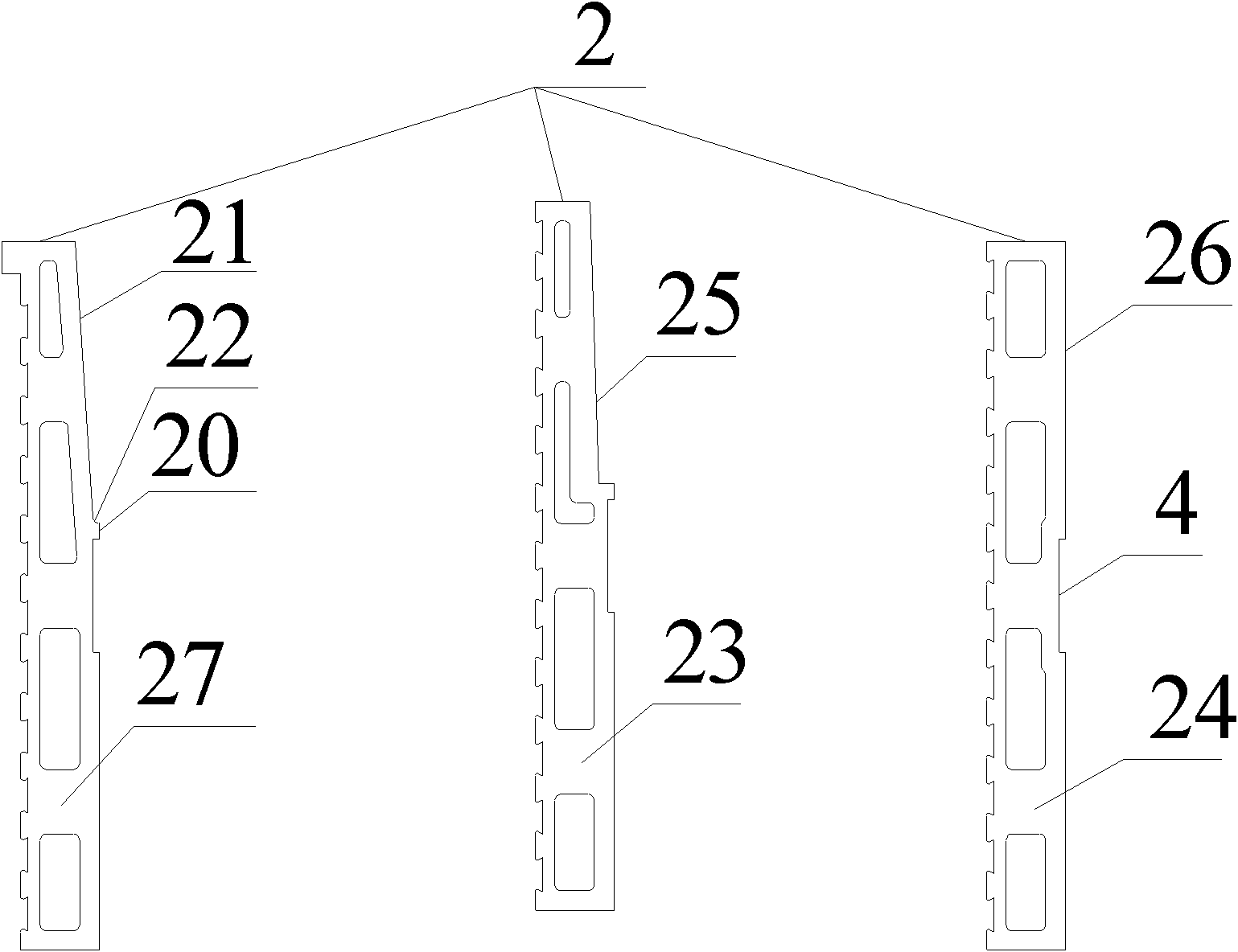

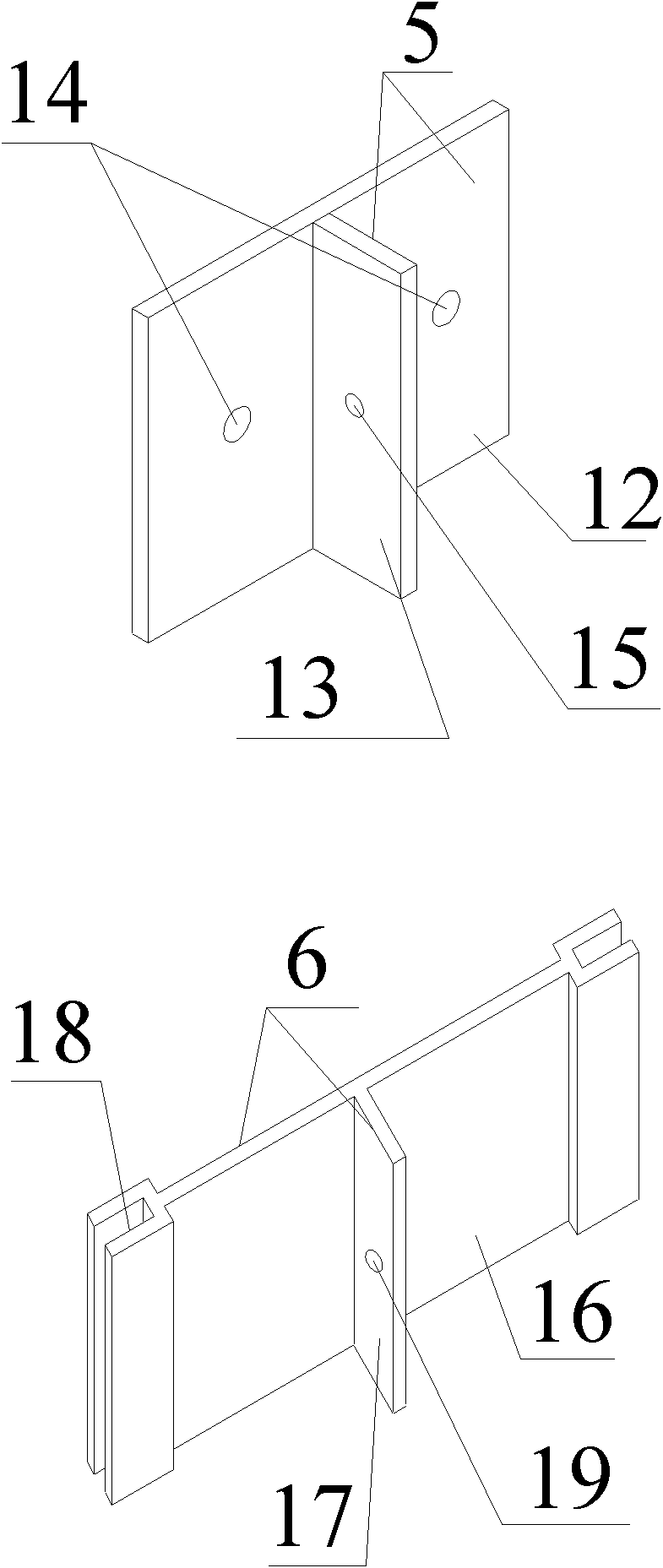

[0020] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 6 As shown, the sub-frames of energy-saving doors and windows in fully enclosed buildings are composed of ordinary veneer sub-frame plates 24 and blanking sub-frame plates 27, and the upper sub-frame plates 10 and side sub-frame plates 9 are the materials of ordinary veneer sub-frame plates , the lower sub-frame plate 8 is the material of the blanking sub-frame plate 27; it includes a corner code 1, a sub-frame plate 2 made of an environmentally friendly recycled composite wood-plastic modified material, which is made of an environmentally friendly recycled composite wood-plastic modified material The sub-frame plates 2 are connected by corner codes 1 to form a fully enclosed sub-frame 3, and the inner side of the fully-enclosed sub-frame 3 formed by connecting the sub-frame plates 2 made of the environmentally friendly recycled composite plastic wood modified material is provided with a connectin...

Embodiment 2

[0021] Embodiment 2: as figure 1 , figure 2 , image 3 , Figure 5 , Figure 6 As shown, the sub-frame of the energy-saving door and window of a fully enclosed building is composed of a brick veneer sub-frame plate 23 and a blanking sub-frame plate 27, and the upper sub-frame plate 10 and the side sub-frame plate 9 are materials for the face brick veneer sub-frame plate 23 , the lower sub-frame plate 8 is the material of the blanking sub-frame plate 27; it includes a corner code 1, a sub-frame plate 2 made of an environmentally friendly recycled composite wood-plastic modified material, which is made of an environmentally friendly recycled composite wood-plastic modified material The sub-frame plates 2 are connected by corner codes 1 to form a fully enclosed sub-frame 3, and the inner side of the fully-enclosed sub-frame 3 formed by connecting the sub-frame plates 2 made of the environmentally friendly recycled composite plastic wood modified material is provided with a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com