Processing device and method for removing fine particulate matter in automobile tail gas by electrostatic spraying

A technology of electrostatic spraying and treatment device, which is applied to exhaust devices, mufflers, engine components, etc., can solve the problems of low removal efficiency, large water consumption, large device volume, etc., and achieves enhanced Coulomb force effect and small water consumption. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

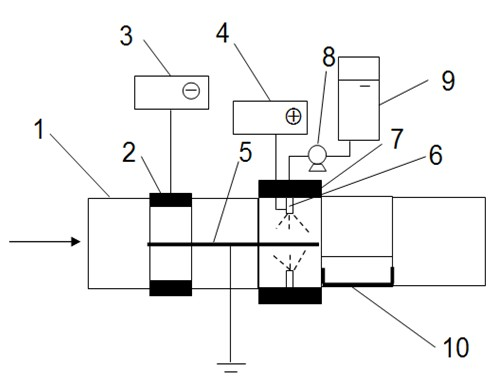

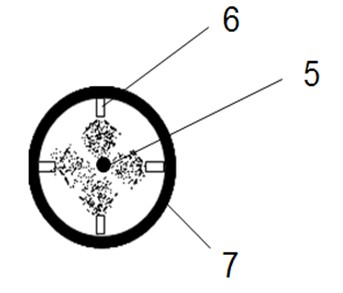

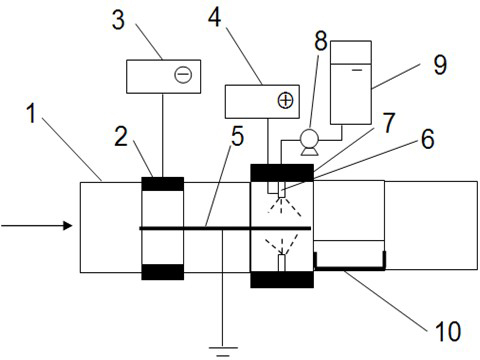

[0015] Such as figure 1 The shown device has an exhaust gas connecting pipe 1, which can be directly connected with the exhaust pipe of the automobile, and can also be appropriately lengthened to replace the exhaust pipe of the automobile. The ring-shaped inductive charging electrode 2 is tightly socketed on the inner wall of the front section of the exhaust gas connecting pipe 1, and an insulator is arranged between the inductive charging electrode 2 and the exhaust gas connecting pipe 1, and the inductive charging electrode 2 is fixedly connected to the exhaust gas connection through the insulator. On the inner wall of the pipe 1, it is insulated from the exhaust gas connection pipe 1. Also fixedly connect the electrostatic spray device 6 on the inner wall of the tail gas connecting pipe 1 rear section, an annular insulator 7 is set between the electrostatic spray device 6 and the tail gas connecting pipe 1, so that the electrostatic spray device 6 and the tail gas connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com