Process for producing needle-punched electrostatic net by using polypropylene electrostatic fiber and acrylonitrile fiber and application thereof

An acrylonitrile fiber and electrostatic fiber technology, which is applied in textiles and papermaking, chemical instruments and methods, dispersed particle filtration, etc. problems such as the mixing ratio of particles to achieve uniform and stable electrostatic charge distribution, low production cost, and the effect of enhancing Coulomb force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

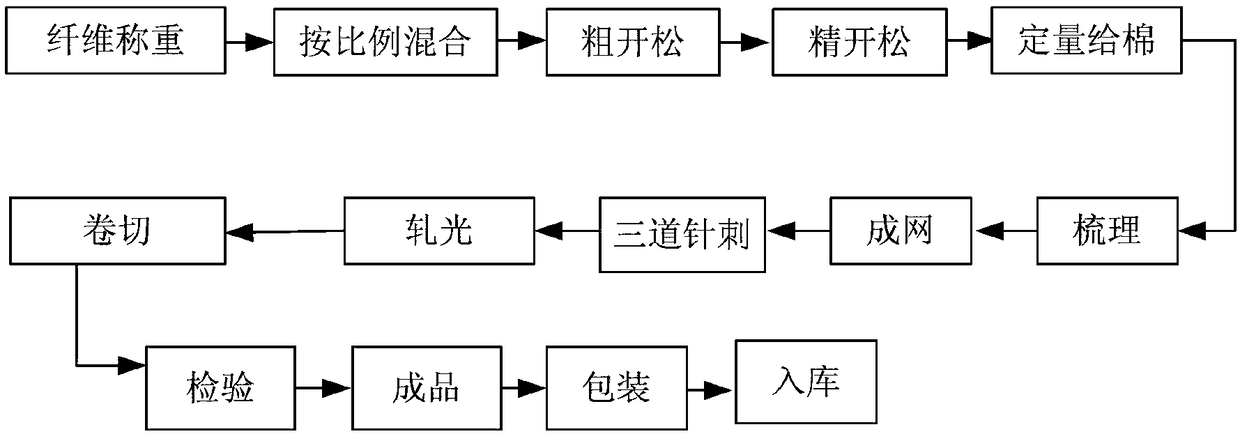

[0016] The present invention proposes a technique of utilizing polypropylene electrostatic fibers and acrylonitrile fibers to produce needle-punched electrostatic nets, such as figure 1 shown, including the following steps:

[0017] Step 1. Weighing the fiber raw material, the fiber raw material is composed of polypropylene electrostatic fiber and acrylonitrile fiber, wherein the weight percentage of polypropylene electrostatic fiber is 55% to 90%, and the weight percentage of acrylonitrile fiber is 10% to 45%. Under the condition that the relative humidity of the workshop reaches 80% to 100%, an antistatic agent is applied to the fiber raw material in advance, and the weight percentage of the antistatic agent to the fiber raw material is 0.05% to 0.10%. Mixing, coarse opening, fine opening, quantitative feeding, carding, and laying are carried out in sequence in order to form a uniform fiber web with a thickness of 8mm to 15mm;

[0018] Step 2, the fiber web obtained in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| wind resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com