A phase-controllable multi-electron injector cold-cathode electron gun with microwave modulation

A phase modulation and multi-electron injection technology, applied in the field of electron guns, can solve the problems of easy breakage or short circuit of the filament, difficult phase matching of radiation sources, complicated structure of hot cathode, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

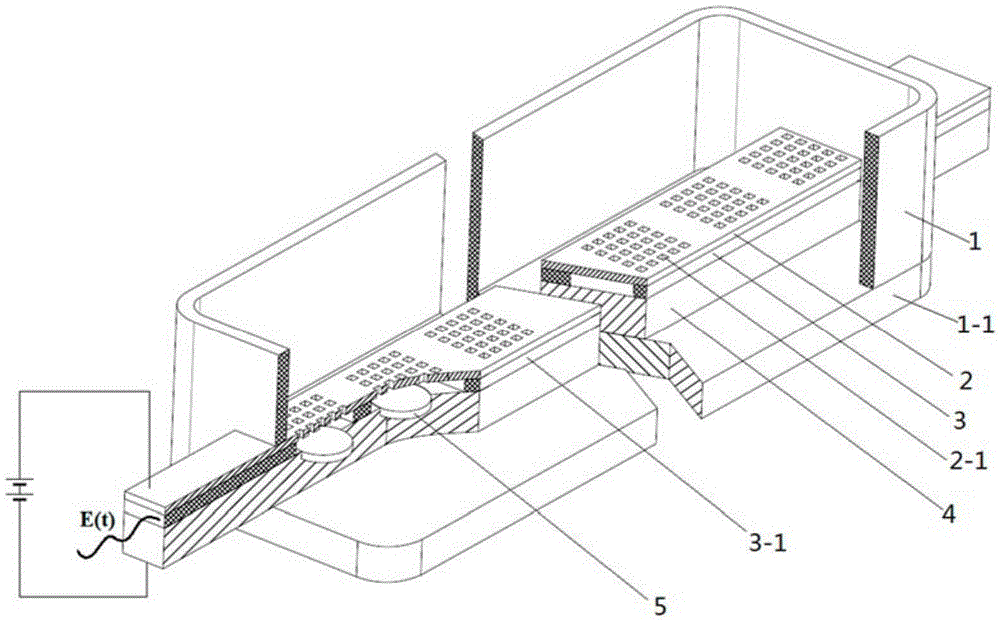

Embodiment 1

[0020] Take the multi-injection cold-cathode electron gun used for the miniature electric vacuum radiation source in the 3 mm frequency band as an example: the inner cavity width of the electron gun housing 1 is 5 mm, the long side is 10 mm, the height is 5 mm, the wall thickness is 2 mm, and the inner wall chamfers the arc curvature For radius 1mm, material is 99 # Ceramic, its lower end is sealed with the base 1-1, and its upper end is connected with the resonant system to form a sealed vacuum chamber when in use, and the vacuum degree can reach 10 -5 Pa; base 1-1 material is also 99 # Ceramic, (length x width x thickness) 14 x 7 x 4mm. The microwave input layer 3 (length×width×thickness) is 20×2×0.25mm. There are three through holes in the microwave input layer, and the (length×width×thickness) of each hole is 2×1.8×0.25mm. This implementation case According to the requirements, the phases of the microwaves in the microwave input layer are the same when they pass through ...

Embodiment 2

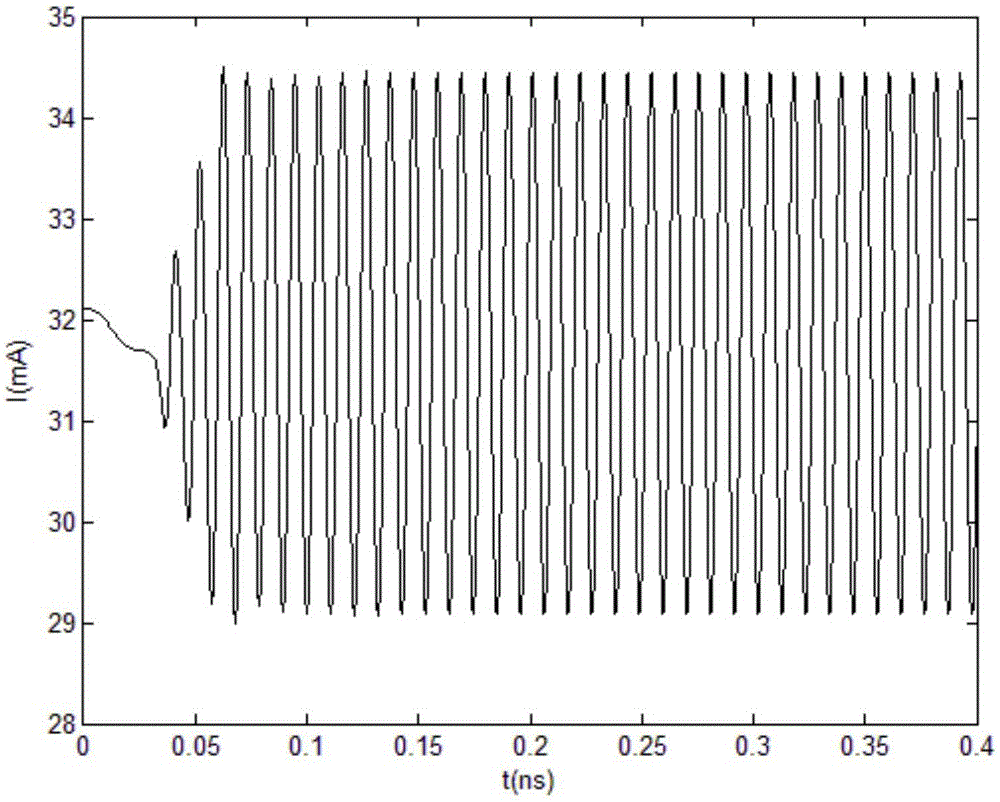

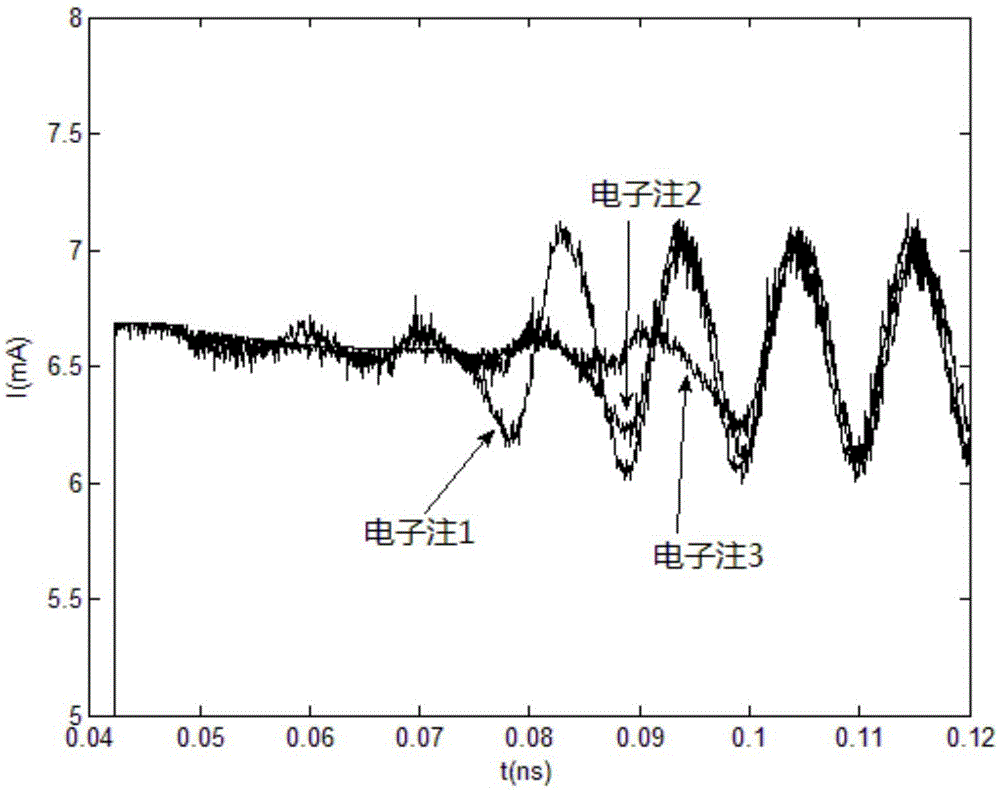

[0023] Still take the multi-injection cold-cathode electron gun for the miniature electric vacuum radiation source of the 3 mm frequency band as an example: wherein the electron gun housing 1, the base 1-1, the electron injection output hole 2-1, the interaction chamber 3-1, the cold cathode 5. Its structure and size are the same as those of Embodiment 1; this embodiment requires that the phases of microwaves passing through the first and third interaction cavities be the same, and that the phases of microwaves passing through the second interaction cavity are the same as those of the first and third interaction cavities. The phase of the interaction cavity is opposite. Through the simulation of the three-dimensional electromagnetic simulation software "CSTMICROWAVESTUDIO", it is obtained that the center distance between the holes in the microwave input layer 3 is 3.86mm, so the arrayed electron injection and output holes on the upper electrode plate 2- 1 The distance between t...

Embodiment 3

[0026] Take the multi-injection cold-cathode electron gun used for the miniature electric vacuum radiation source in the 3 mm frequency band as an example: the inner cavity width of the electron gun housing 1 is 5 mm, the long side is 24 mm, the height is 5 mm, the wall thickness is 2 mm, and the inner wall chamfering arc curvature For radius 1mm, material is 99 # Ceramic, its lower end is sealed with the base 1-1, and its upper end is connected with the resonant system to form a sealed vacuum chamber when in use, and the vacuum degree can reach 10 -5 Pa; base 1-1 material is also 99 # Ceramic, (length×width×thickness) 28×7×4mm; microwave input layer 3 (length×width×thickness) 34×2×0.25mm, made of polytetrafluoroethylene, six through holes are set in the microwave input layer , the (length×width×thickness) of each hole is 2×1.8×0.25mm. The requirement that the phase is the same and opposite to the first and third phases when acting on the cavity; therefore, through the three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com