A cold cathode electron gun modulated by microwave

An electron gun and cold cathode technology, which is applied in the field of electron guns, can solve problems such as filament breakage or short circuit, high cost, and high cathode temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

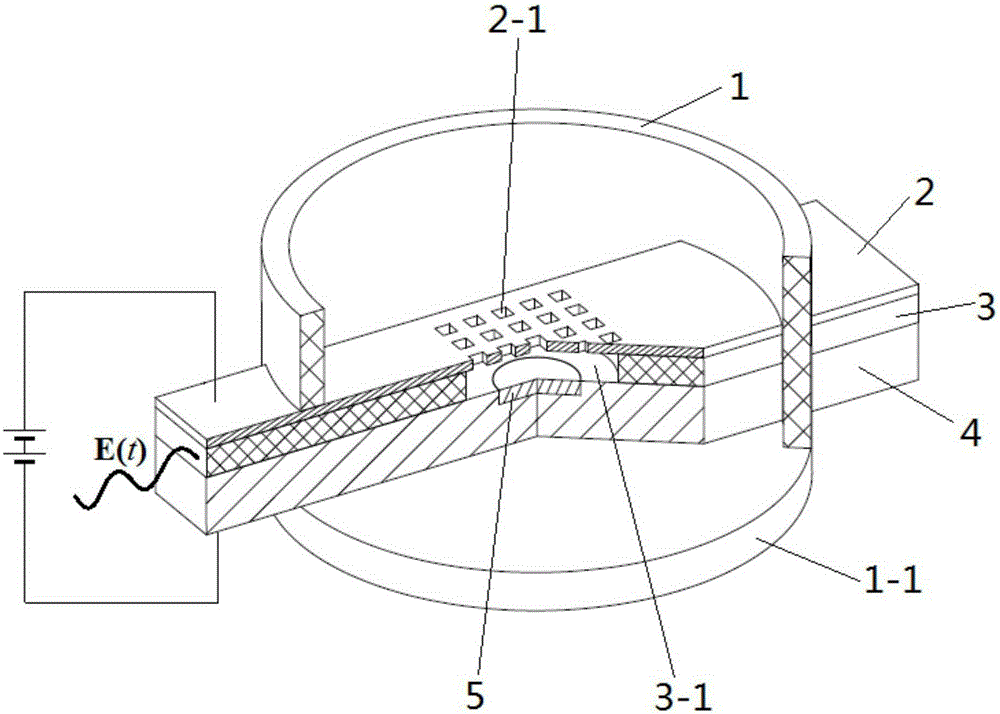

[0013] Take the cold-cathode electron gun used for the miniature electric vacuum radiation source in the 3mm frequency band as an example: the electron gun shell 1 has an inner diameter of φ5mm, an outer diameter of φ7mm, and a height of 5mm, and the material is 99 # Ceramic, its lower end is sealed with the base 1-1, and its upper end is connected with the resonant system to form a sealed vacuum chamber when in use, and the vacuum degree can reach 10 -5 Pa. The electron gun core composed of the microwave input layer 3, the lower electrode plate 4, its cold cathode 5, and the upper electrode plate 2 traverses the electron gun housing 1, and the electron injection and output holes 2-1 are placed at the axial position of the inner cavity of the housing, and the two ends are respectively Stretch out of the shell, seal and fix the base 1-1 and the electron gun shell 1 into one body through the lower electrode plate 4, both sides of the gun core and the top surface of the upper ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com