Reciprocating rolling generator and application method thereof

A generator and reciprocating technology, applied in the direction of machines/engines, mechanical equipment, mechanisms for generating mechanical power, etc., can solve the problems of low energy conversion rate and poor continuity of energy conversion, so as to improve power generation efficiency, increase service life, The effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

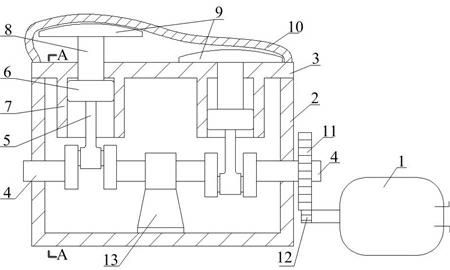

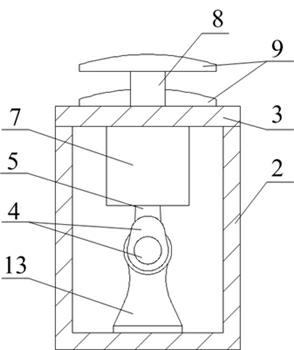

[0037] Such as figure 1 with image 3 As shown, the reciprocating rolling generator includes a generator 1 and an energy transfer device connected to the generator; the energy transfer device includes a box body composed of a box-shaped base 2 and a box cover 3, which is connected to the generator 1 The crankshaft 4 is placed in the box and penetrates both sides thereof, and a transmission device that passes through the cover 3 and is connected to the crankshaft 4; the transmission is mainly composed of a slide 7 connected to the lower part of the cover 3 and a slide 7 The inner slider 6, the connecting rod 5 connecting the slider 6 and the crankshaft 4, the support rod 8 passing through the box cover 3 and connected with the slider 6, and the pressure plate 9 arranged above the box cover 3 and connected with the support rod 8 There are two sets of transmission devices. In order to ensure the more efficient operation of the present invention, correspondingly, the connecting rod...

Embodiment 2

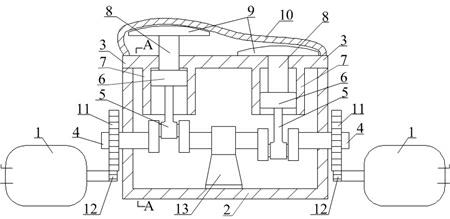

[0049] Such as figure 2 with 3 As shown, the difference between this embodiment and Embodiment 1 is that both ends of the crankshaft 4 are provided with driving gears 11, and two generators 1 are connected by meshing with corresponding driven gears 12. Such a setting can drive the two generators 1 to generate electricity at the same time when the crankshaft 4 rotates, make full use of the energy transmitted by the rotation of the crankshaft 4, increase power output, greatly improve power generation efficiency and reduce resource occupancy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com