A helical gas spring

A gas spring, helical technology, applied in the field of spring manufacturing, can solve the problems of insufficient gas spring deformation stroke, small softness and hardness adjustment range, and inability to ensure comfort, etc., to save transportation costs, good horizontal and vertical ventilation, The effect of large deformation stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

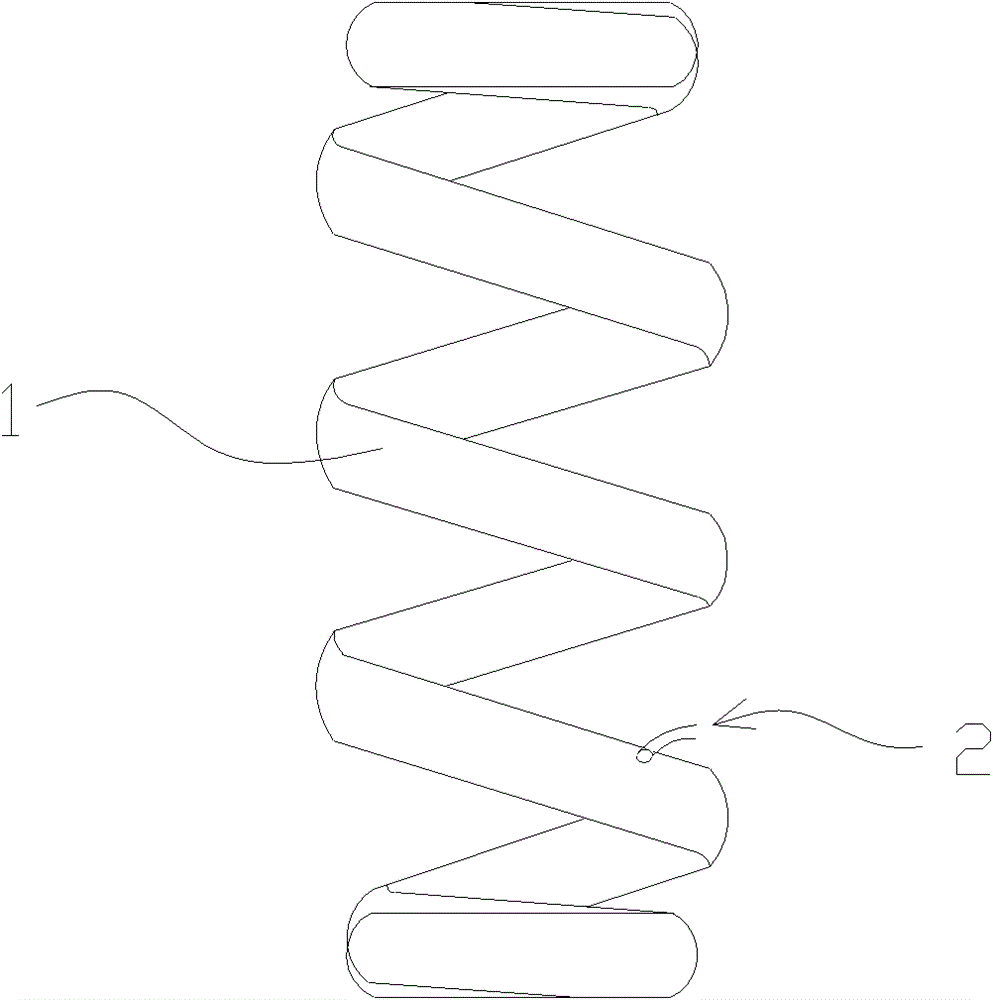

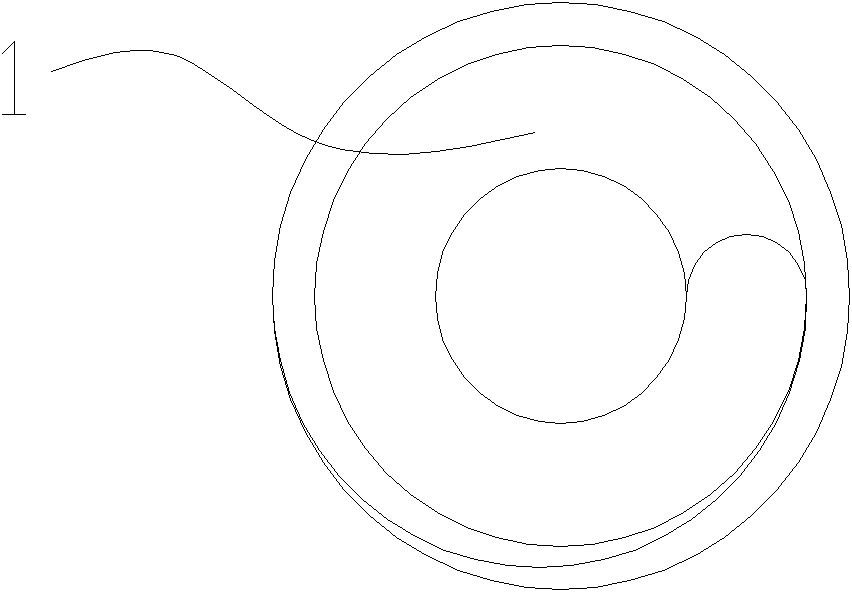

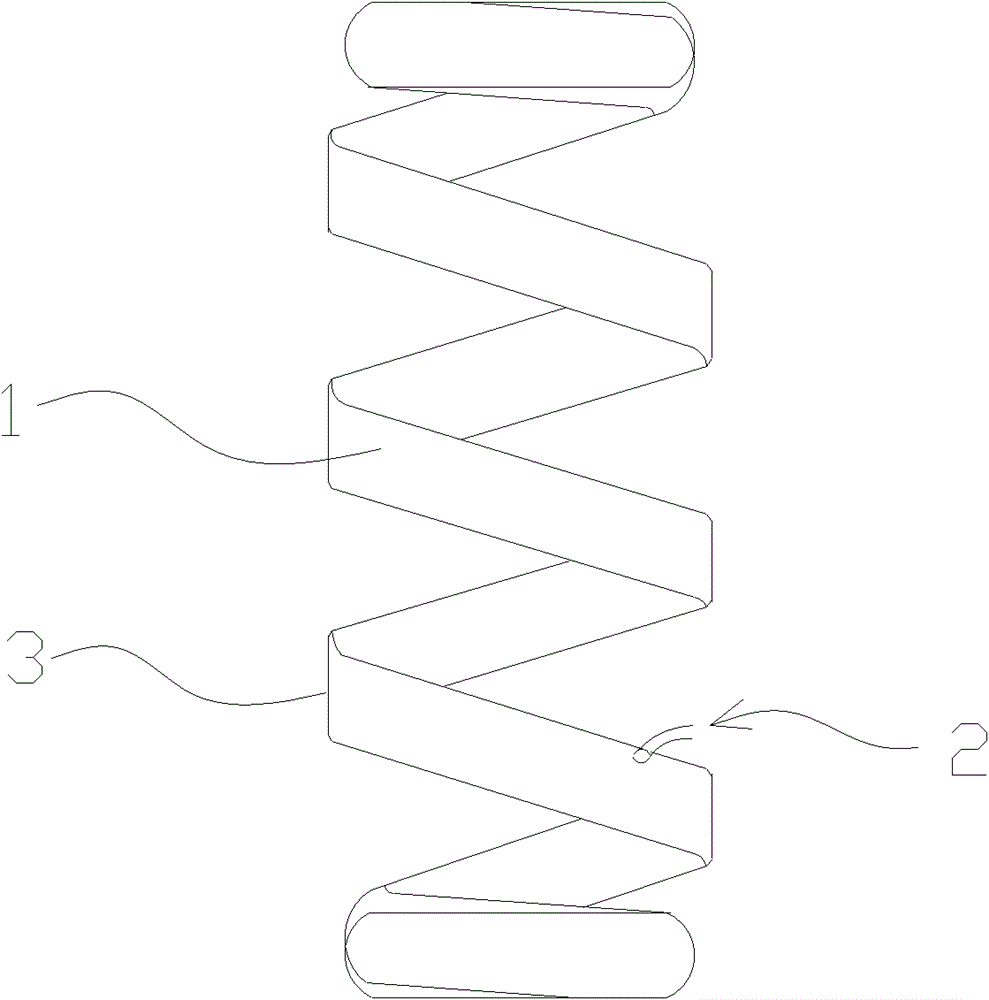

[0021] Such as figure 1 , figure 2 As shown, a helical gas spring described in the present invention includes a spring body, and the spring body is composed of an air column 1 with a pressure gas chamber, the air column 1 is helical, and the air column 1 is provided with a vent hole 2 communicating with the containing cavity, through which both inflation and exhaust are completed, or there may be two vent holes 2, one for inflation and one for exhaust. The air column 1 is helically formed by a cylindrical body, and the air column 1 is vertically arranged with horizontal and vertical ventilating passages. The diameter of the upper and lower openings of the air column 1 is smaller than the diameter of the spiral opening in the middle, and the diameter of the spiral openings in the middle is the same. The upper and lower openings of the air column 1 are lined with hard rings, and the spring body is covered with an outer cover, which are all shown in the figure. The at least o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com