Multi-directional split type irrigation water outlet

A water outlet, split-type technology, applied in the direction of branch pipelines, pipes, pipes/pipe joints/fittings, etc., can solve the problems of complex production structure, easy loss, and loss of cover, so as to reduce construction costs and ensure tight sealing , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

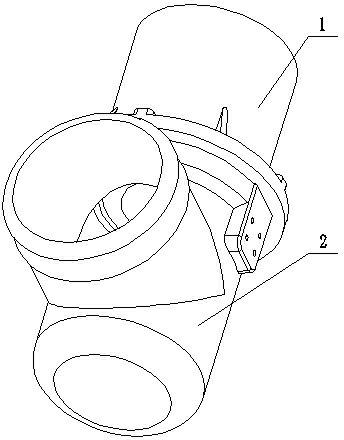

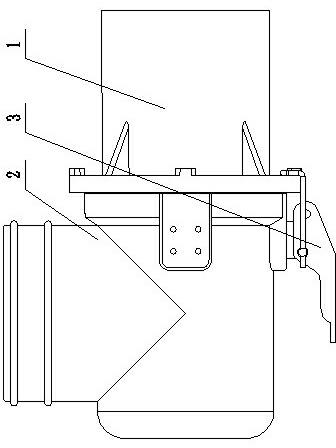

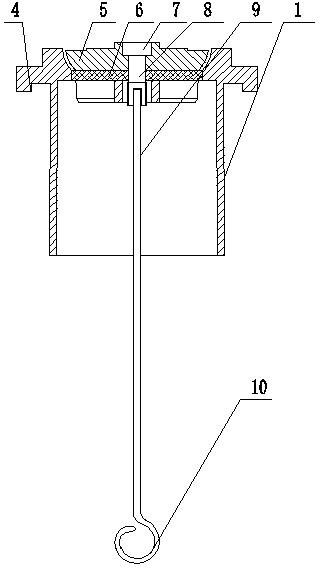

[0015] See attached Figure 1-2 , the water outlet disclosed in the present invention includes a water outlet elbow 2, and also includes a vertical branch pipe 1 arranged at the pipe mouth. 3 connections are fixed. The vertical branch pipe 1 and the water outlet elbow 2 are made of glass fiber reinforced plastic respectively. The vertical branch pipe 1 and the water outlet elbow 2 are of split structure. The vertical branch pipe 1 is directly connected with the pipeline buried in the field and placed in the field. Standby; the water outlet elbow 2 can be directly carried by the irrigation user. When in use, the user adjusts the water outlet direction of the water outlet elbow 2 according to needs, and after the two are docked, they can be connected with the pull buckle 3. The periphery of the end of the vertical branch pipe 1 is provided with a hook 4 used in conjunc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com