Novel plastic pipe fitting capable of preventing inner flanging

A technology of plastic pipe fittings and inner flanging, which is applied in the direction of pipes/pipe joints/pipes, pipe connection layout, mechanical equipment, etc., can solve the problems of increasing energy consumption, water head loss, increasing the cost of water supply enterprises, etc., to ensure welding quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with drawings and embodiments.

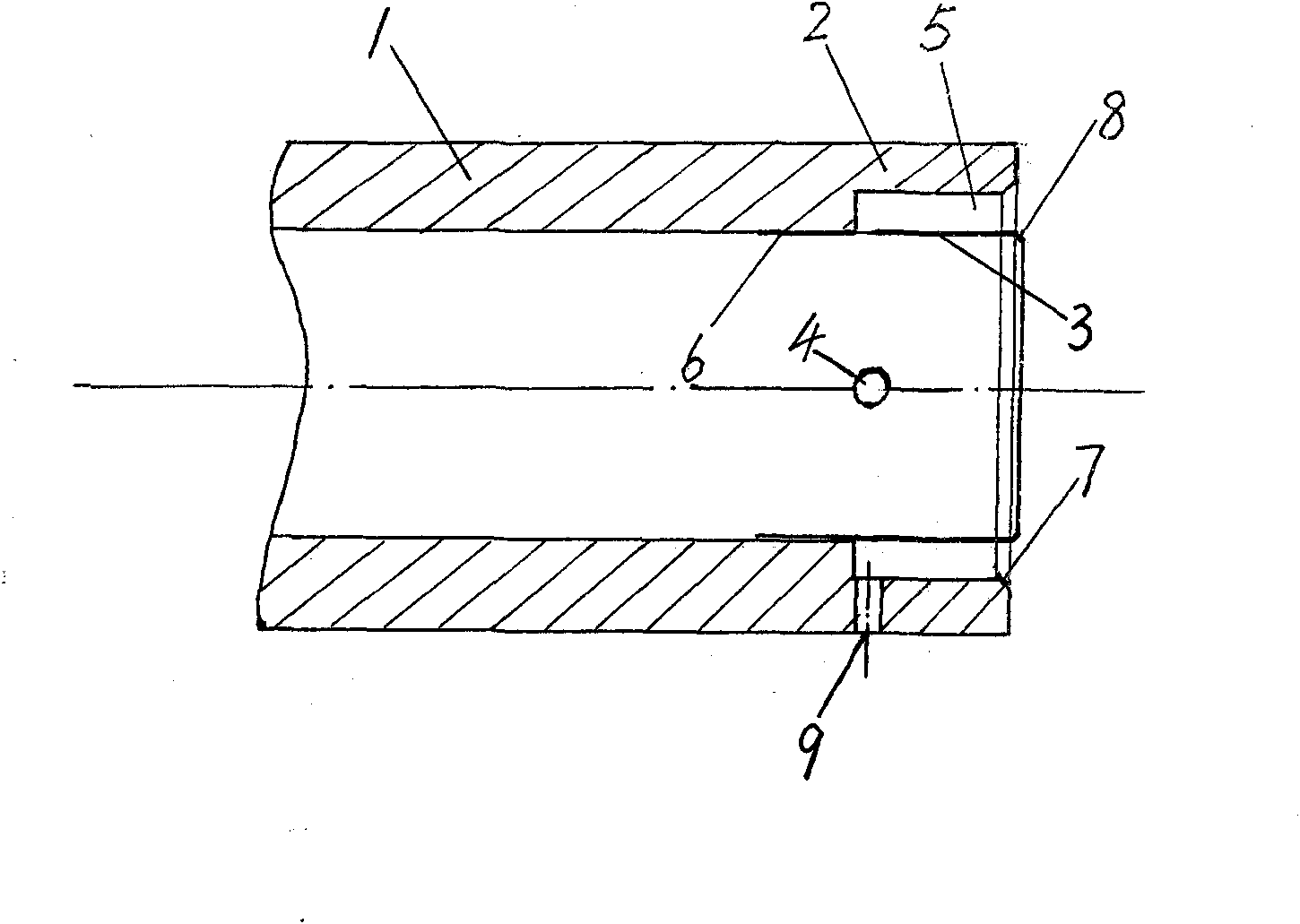

[0009] figure 1 Among them, at least one end of the small-diameter plastic pipe fittings (1) connected by hot melt socket has an annular socket (5), and the socket (5) is provided with an outer ring (2) and an inner ring. The outer ring (2) is a ring made of the same material as the pipe, and the inner diameter of the outer ring (2) is equal to the inner diameter of the socket of the plastic pipe fitting connected by hot-melt socket of the same specification. Angle (7); Inner ring is a thin-walled stainless steel ring, and its outer diameter is equal to the inner diameter of the plastic pipe of the same specification, and there is a chamfer (8) toward the inboard of the pipe fitting (1) on the outer side of the inner ring port. The axial length of the upper section of the inner ring (3) is 1-2 mm longer than the port of the outer ring, and the lower section of the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com