Oxygen-supplementing biomass combustion furnace

A biomass burning furnace and oxygen supplement technology, which is used in household furnaces/stoves, solid heating fuels, lighting and heating equipment, etc., can solve the problems of low thermal energy use efficiency, insufficient fuel combustion, waste of water resources, etc. The effect of improving fuel combustion efficiency, heat utilization efficiency, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

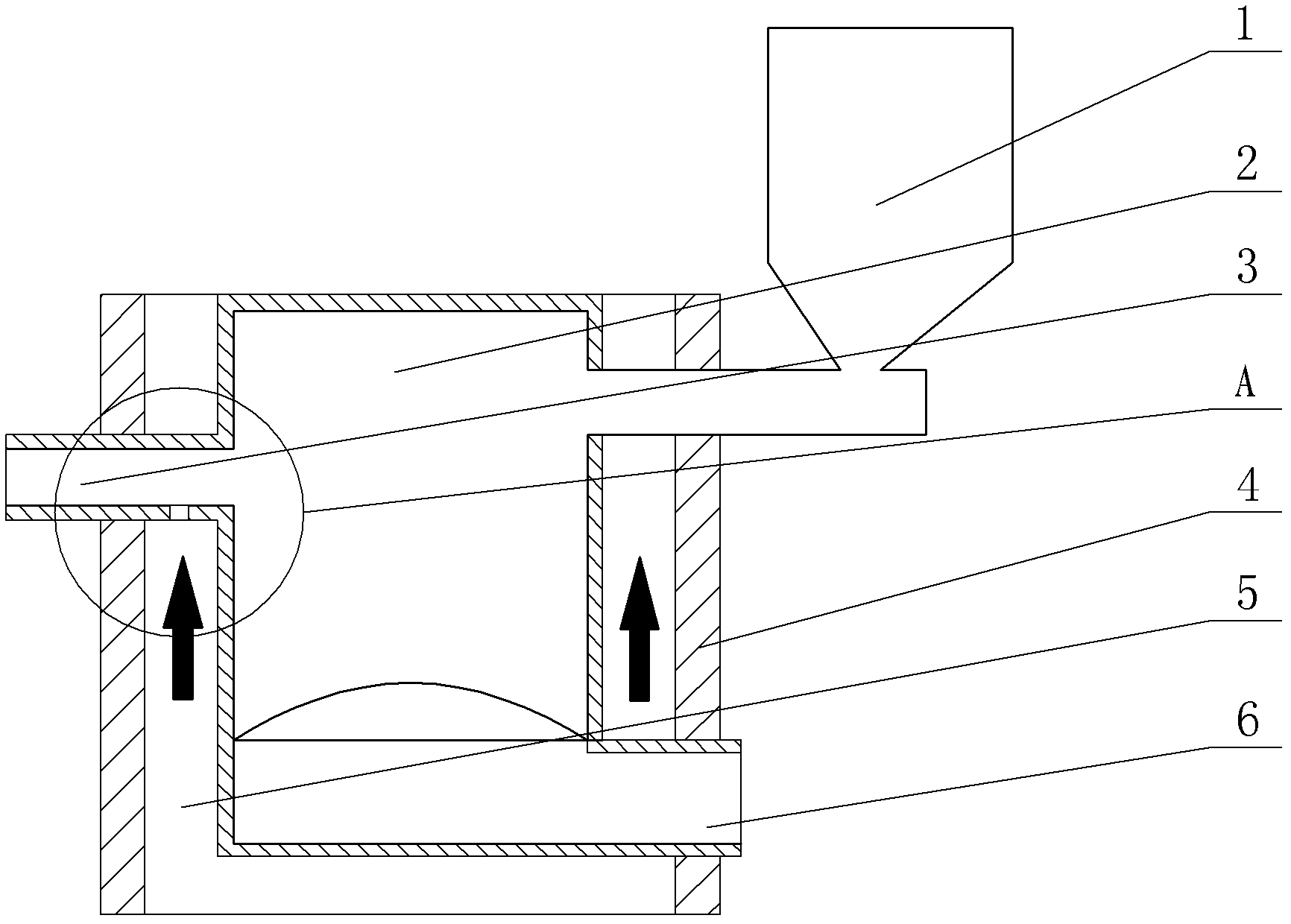

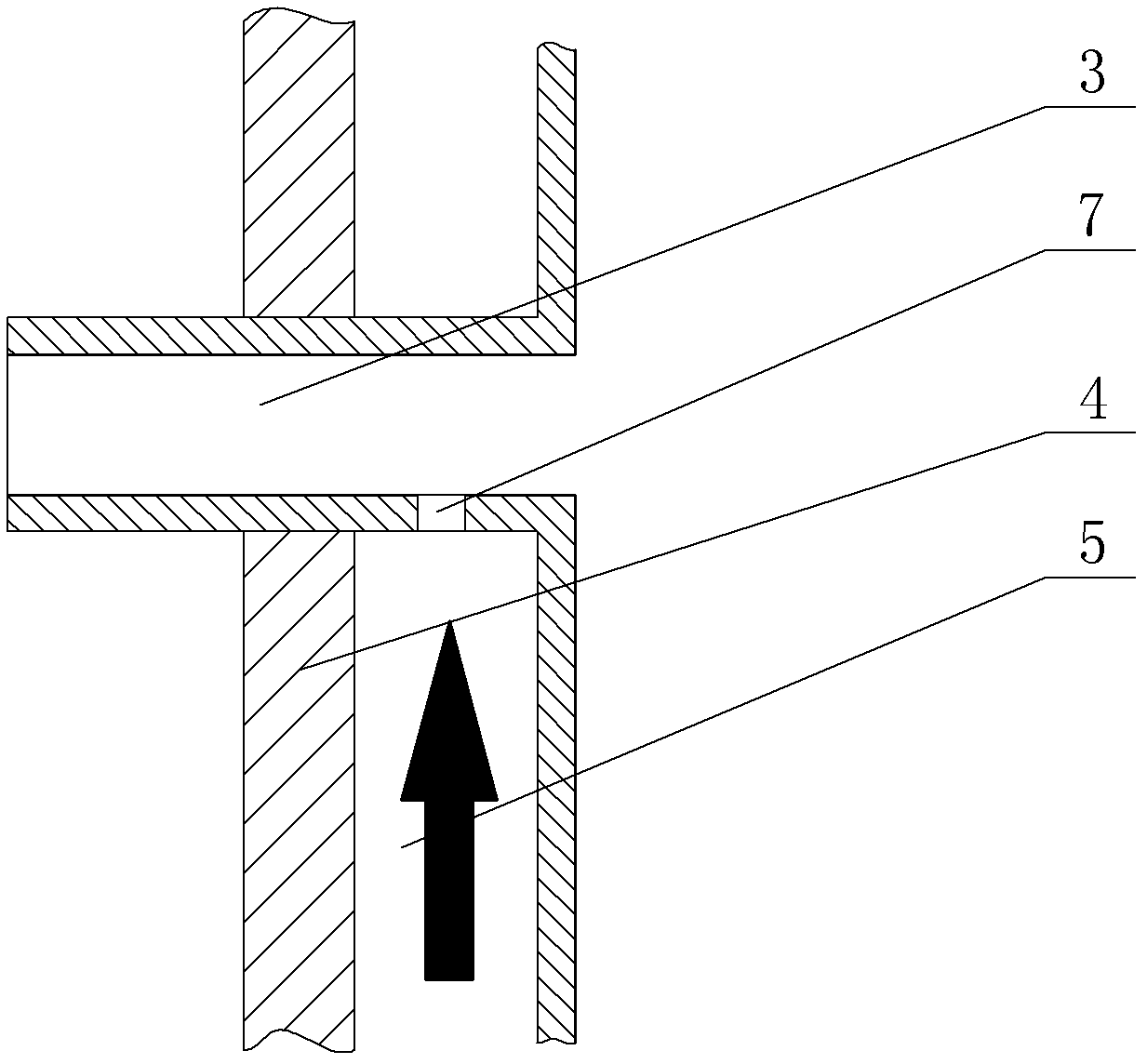

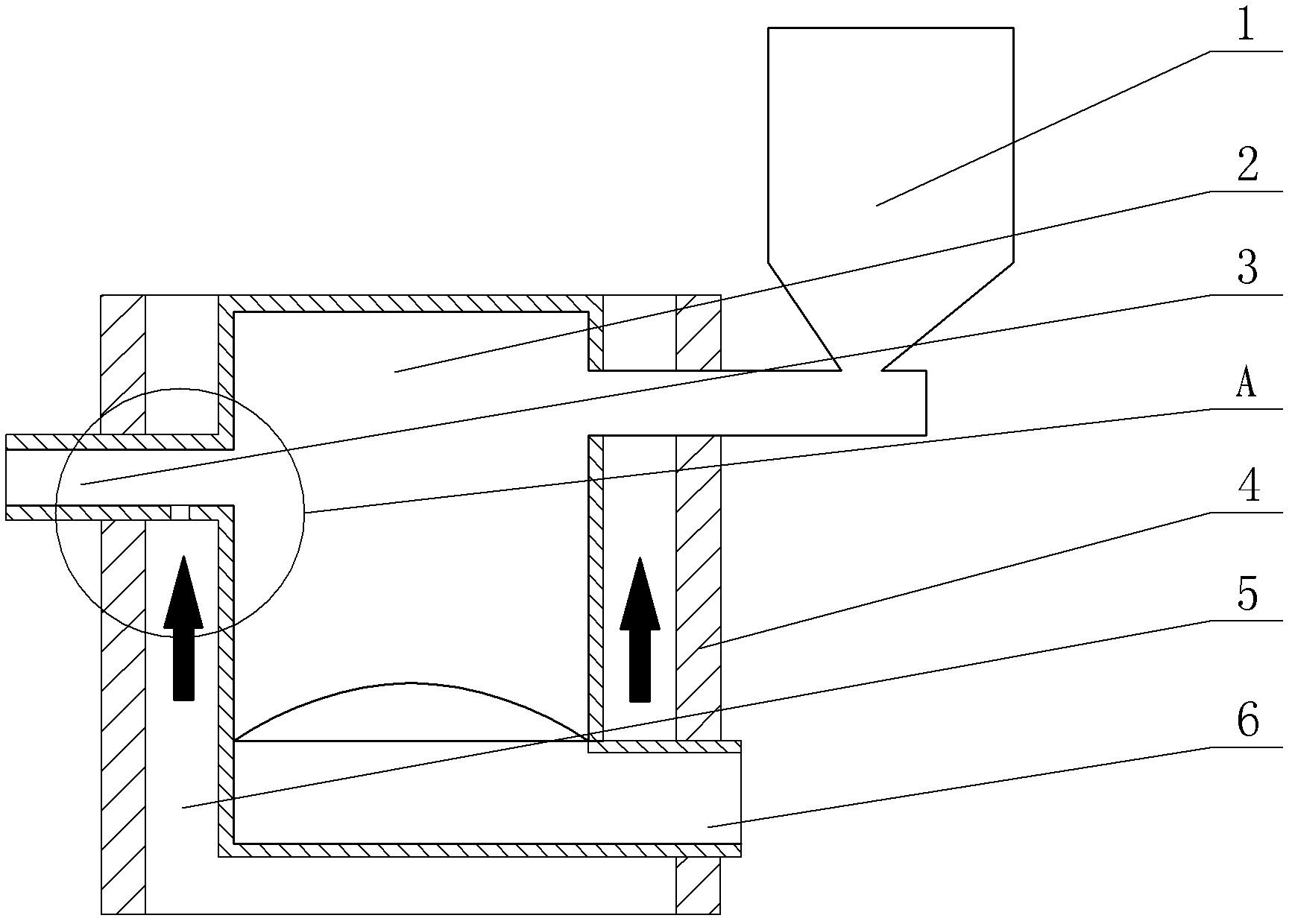

[0010] Below in conjunction with accompanying drawing, the preferred embodiment of a kind of oxygen-supplementing biomass combustion furnace of the present invention is described in detail:

[0011] Such as figure 1 As shown, the main body of the oxygen-supplementing biomass combustion furnace is the furnace 2, which is a cylindrical hollow cavity made of high-temperature-resistant special materials, which will not deform or oxidize and corrode at high temperatures. A hopper 1 is provided at a position near the top of the furnace 2 to transport biomass fuel into the furnace 2 . A flame port 3 is provided on the waist of the furnace 2 opposite to the hopper 1, and the flame burned in the furnace 2 is ejected from the flame port 3 for reuse. An air inlet 6 is provided at the bottom of the furnace 2, and oxygen is delivered into the furnace 2 by means of natural suction or other methods.

[0012] The furnace 2 is entirely placed in a cylindrical heat-resistant casing 4 , the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com