Ultrasonic subcooling eliminating device

A supercooling removal and ultrasonic technology, which is applied in the manufacture of ice, lighting and heating equipment, ice making, etc., can solve the problems of not being able to remove supercooling well, the efficiency of removing supercooling is not high, and the removal of supercooling is not sufficient. Achieve the effect of improving the effect of supercooling relief, good effect of supercooling relief, and sufficient effect of supercooling relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

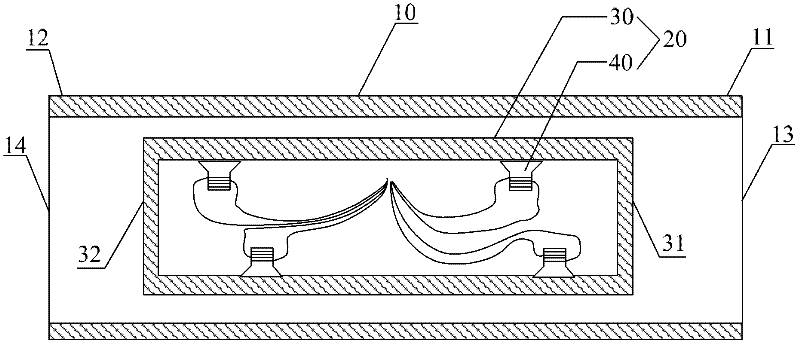

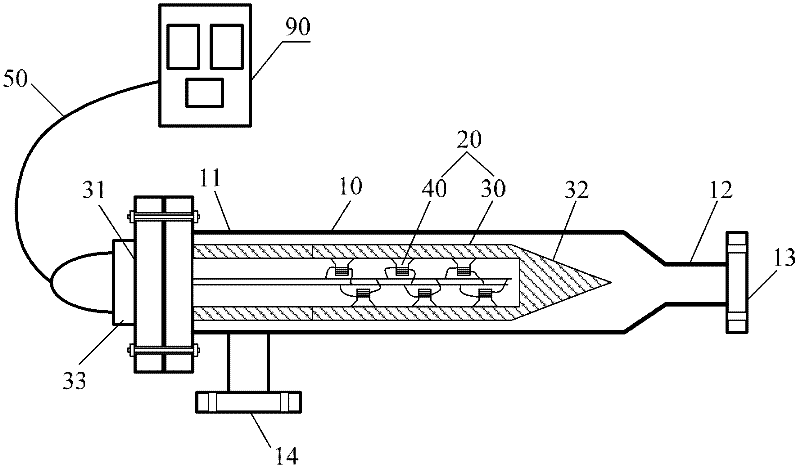

[0039] Embodiment one: like figure 2As shown, the first end 31 of the ultrasonic device casing 30 is fixedly connected to the first end 11 of the outer tube 10 , that is, the ultrasonic device and the outer tube 10 are directly fixedly connected. The first end 31 of the casing 30 is fixed, and the rest of the casing 30 (including the second end) can be directly "suspended" in the outer tube 10, or can be defined by further reinforcement means, for example, between the casing 30 and the outer tube 10. A limiting component or a connecting component is provided between the tubes 10 to limit the relative spatial position between the housing 30 and the outer tube 10 . The first end 31 of the housing 30 and the first end 11 of the outer tube 10 can adopt various existing connection techniques, such as conventional flange connection methods. To improve the sealing effect between the liquid and prevent liquid leakage, a sealing member should also be provided at the flange connecti...

Embodiment 2

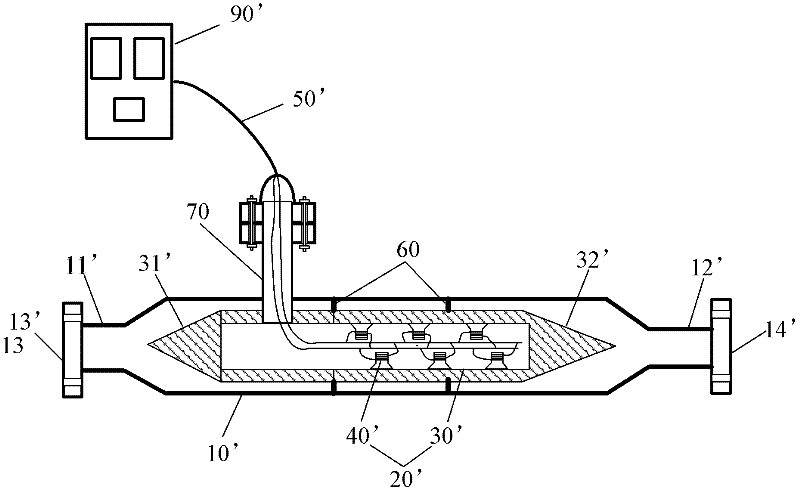

[0044] Embodiment two: like image 3 , Figure 4 As shown, the ultrasonic device 20' of this embodiment is provided with a supporting fixture 60 between the outer wall surface of the casing 30' and the inner wall surface of the outer tube 10'. The supporting and fixing member 60 can adopt an embedded part, that is, the part is not directly fixed with the housing 30' or the outer tube 10', but realizes the gap between the housing 30' and the outer tube 10' through the limiting function of the part. The relative fixation; the supporting fixture 60 can also be a connected component, that is, the component is fixedly connected with the housing 30' and / or the outer tube 10', such as welding, threaded connection and the like. At this time, since the two ends of the outer tube 10' are not blocked, the first outlet 13' and the second outlet 14' of the outer tube 10' can be directly arranged at the two ends 11', 12 of the outer tube 10' respectively. '.

[0045] The outer tube 10'...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com