Underwater blasting explosive bin installation equipment and installation and blasting method

A technology for installing equipment and blasting charges, which is applied in the field of installing equipment and blasting in underwater blasting chambers, and can solve problems such as damaged instruments, blockages, and complicated construction techniques, and achieve the effects of low cost, high efficiency, and simple technical implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

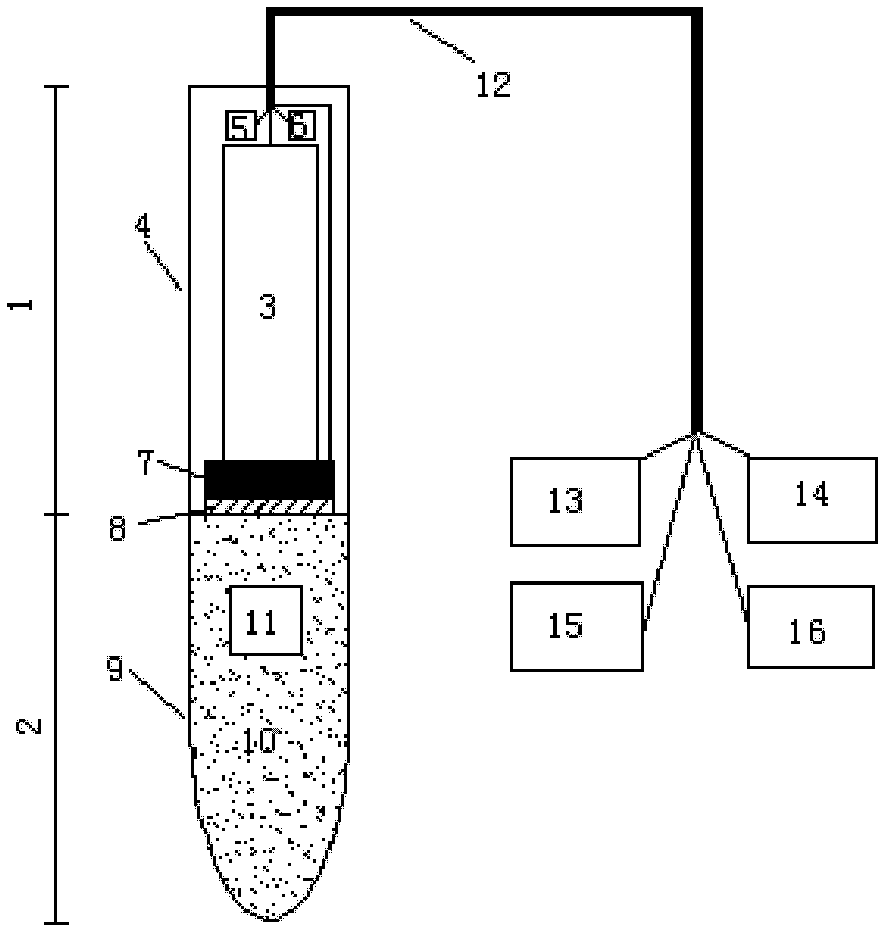

[0035] Embodiment 1: Underwater single-point blasting powder chamber installer and installation blasting method

[0036] Such as figure 1 As shown, the underwater blasting charge chamber installer consists of a propeller 1 and a charge chamber 2.

[0037] Described thruster 1 comprises: excitation motor 3, thruster casing 4, GPS locator 5, displacement sensor 6, lifting electromagnet 7, cable 12; The power is provided by the device 1; the lifting electromagnet 7 is fixed on the bottom of the propeller shell 4, and the excitation motor 3 and the lifting electromagnet 7 are connected to the power supply through the cable 12; the GPS locator 5 and the displacement sensor 6 are arranged on the propeller shell 4 inside.

[0038] The drug store includes: an armature 8, a drug store housing 9, explosives 10, a wireless detonating device 11, a GPS positioning display 13, a displacement sensor display 14, an excitation motor power supply 15 and a lifting electromagnet power supply 16...

Embodiment 2

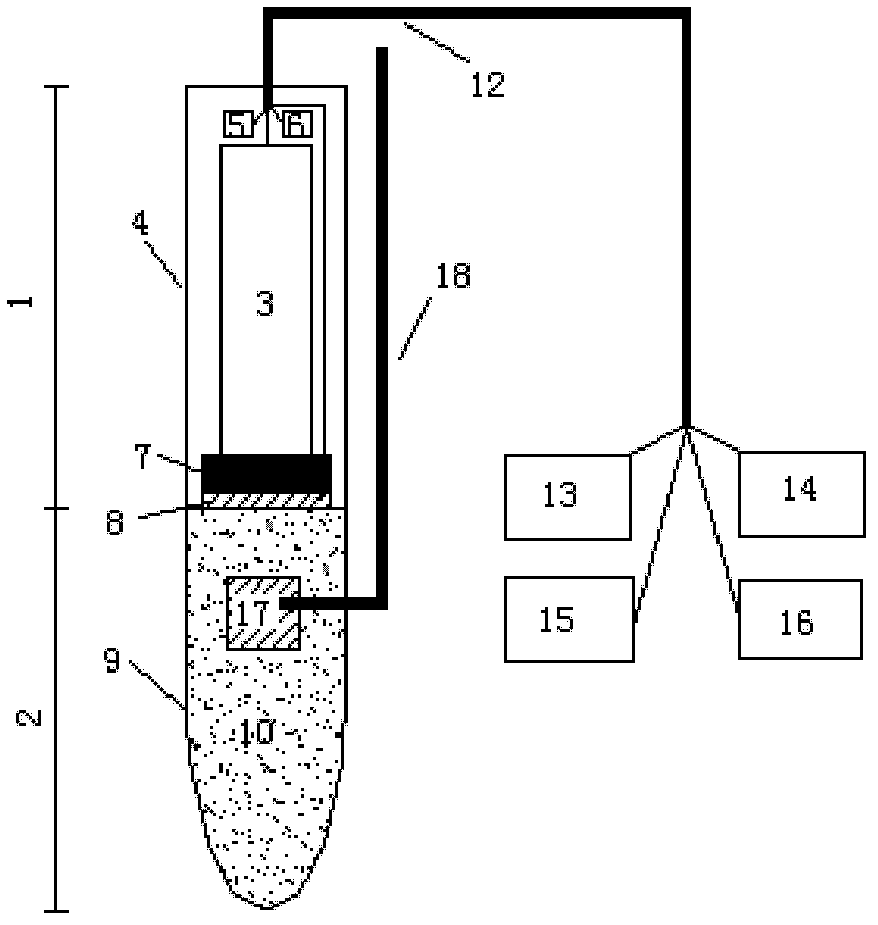

[0048] Embodiment 2: Underwater multi-point blasting powder storehouse installer and installation blasting method

[0049] Such as figure 2 As shown, the underwater blasting charge chamber installer consists of a propeller 1 and a charge chamber 2.

[0050] The propeller 1 includes: an excitation motor 3, a propeller casing 4, a GPS locator 5, a displacement sensor 6, a lifting electromagnet 7, and a cable 12; this part is the same as that of the first embodiment.

[0051] The medicine storehouse 2 includes: armature 8, medicine storehouse shell 9, explosive 10, detonating body 17, detonating cord 18, GPS positioning display 13, displacement sensing display 14, excitation motor power supply 15 and lifting electromagnet power supply 16.

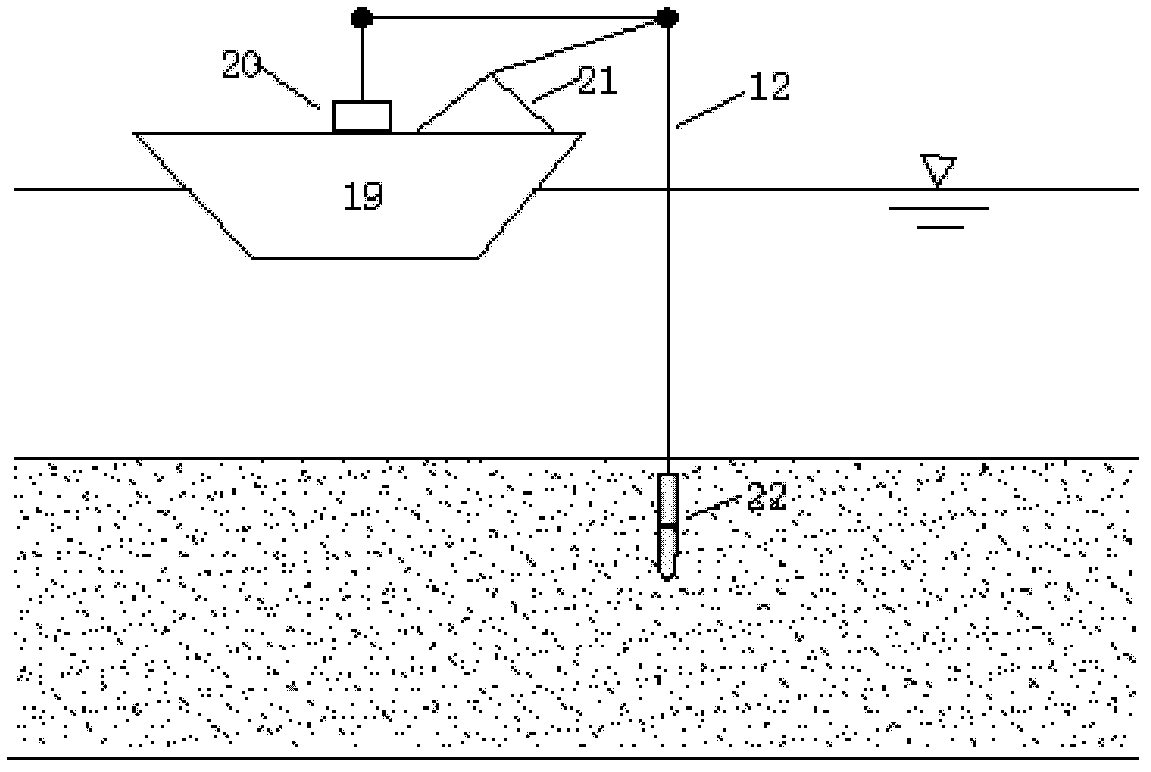

[0052] Such as image 3 As shown, the installation process of the underwater blasting powder warehouse includes equipment such as cables 12, working boats 19, electric power, GPS positioning and displacement control platforms 20, cranes 21...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Barrel diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com