Novel testing device and testing method for sealing performance of pipe plate and heat exchange pipe

A technology of sealing performance and testing equipment, which is applied in the direction of fluid tightness testing, measuring equipment, liquid tightness measurement using liquid/vacuum degree, etc., can solve the problems of non-reusable and cumbersome procedures, and achieve the goal of standardization, The test process is simple and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

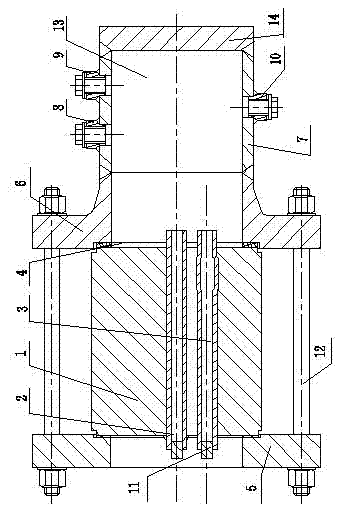

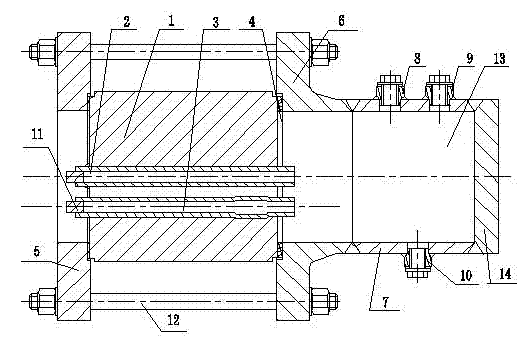

[0023] A new test device for the sealing performance of tube sheets and heat exchange tubes, which consists of: an end cover 5, a test cylinder 1, a sealing gasket and corresponding pipe joints; the tested tube sheet 3 and the test cylinder and the sealing The gasket forms a sealed cavity, and the tube seat A at the highest end is connected to the test cylinder during the test, and the test meter is installed on the tube seat A, and the tube seat B at the bottom end is connected to the test cylinder during the test, and the tube seat B is connected to the test medium inlet pipe, and is The sealing form of the test tube sheet adopts octagonal groove or boss plane for sealing.

Embodiment 2

[0025] In the new test device for sealing performance of tube sheets and heat exchange tubes described in Example 1, the tube sheets to be tested are connected to the test cylinder and the end caps using octagonal groove seals or convex-concave table seals.

[0026] That is, if the tube sheet to be tested is sealed with an octagonal groove, the end cover and the test cylinder are processed into corresponding octagonal grooves to connect with it; if a boss seal is used, the test cylinder is sealed The two ends are processed into a boss form, the end cover and the test cylinder are processed into a concave form, and a gasket matching the sample size is used for sealing, wherein the test cylinder and the end cover , The processing of the test cylinder is matched.

Embodiment 3

[0028] The new type tube sheet and heat exchange tube sealing performance test device described in embodiment 1 or 2, the test tube is sequentially equipped with expansion tubes 2, 3, etc. to form a heat exchange tube bundle, and one end of the test tube passes through The sealing ring is connected to the tested tube sheet, and the other end of the test cylinder has a cylinder end cover 14 . The test cylinder is connected with a pipe socket, the upper part of the pipe socket is connected with the test meter pipe joint 8 and the test medium port pipe joint 9, and the upper part of the pipe seat is connected with the discharge test medium pipe joint 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com