Single-shaped pulling-pressing double-function creepmeter

A uniaxial tension-compression, dual-function technology, applied in the field of experimental instruments, can solve the problems of insufficient tension and compression stability, long time-consuming creep test, insufficient experimental accuracy, etc., so as to improve the accuracy of stress test and improve the accuracy of stress test. , the effect of low experimental cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

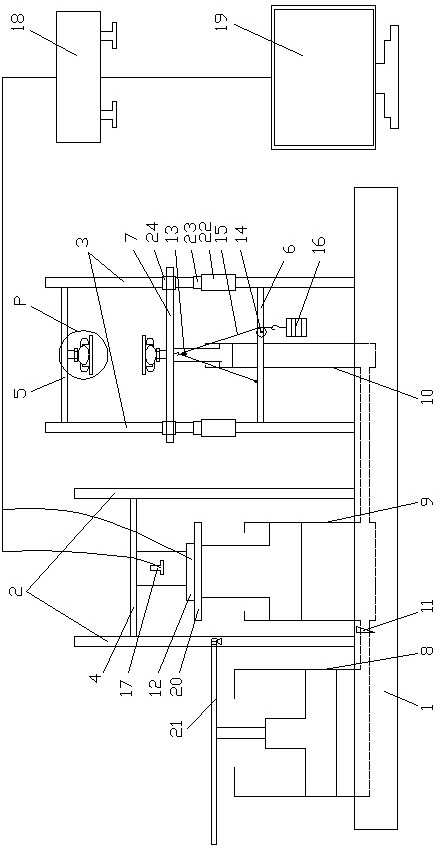

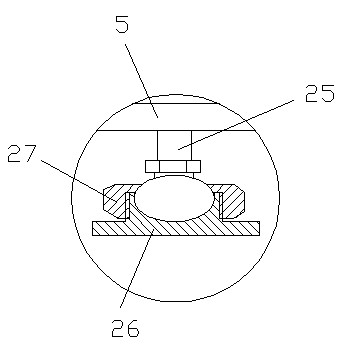

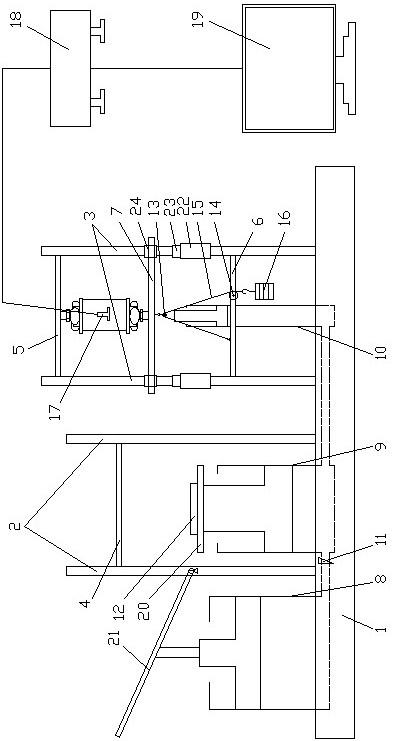

[0026] figure 1 Schematic diagram of the structure when doing the compression creep test for the uniaxial tension-compression creep dual-function creep instrument of the present invention; figure 2 for figure 1 Enlarged view of part P in the center; image 3 It is a schematic diagram of the structure of the uniaxial tension-compression creep dual-function creep instrument of the present invention when performing tensile creep tests.

[0027] As shown in the figure, the uniaxial tension-compression dual-function creep instrument of this embodiment includes a workbench, a tension-compression loading system and a creep data measurement system;

[0028] The workbench comprises a base 1, a first support rod group 2 and a second support rod group 3, the first support rod group 2 and the second support rod group 3 are vertically arranged on the base 1, and the first support rod group 2 A pressure bearing plate 4 is arranged horizontally, and the second support rod group 3 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com