Novel antitheft tag magnetic material, production process thereof and acoustic magnetic antitheft tag

A technology of anti-theft labels and magnetic materials, which is applied in the direction of magnetic materials, magnetic objects, and record carriers used by machines, can solve the problems of changing the resonance frequency of the resonant sheet, increasing the difficulty of sheet material processing, and complicated manufacturing processes, etc., achieving low cost, The effect of simplifying the structure design and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

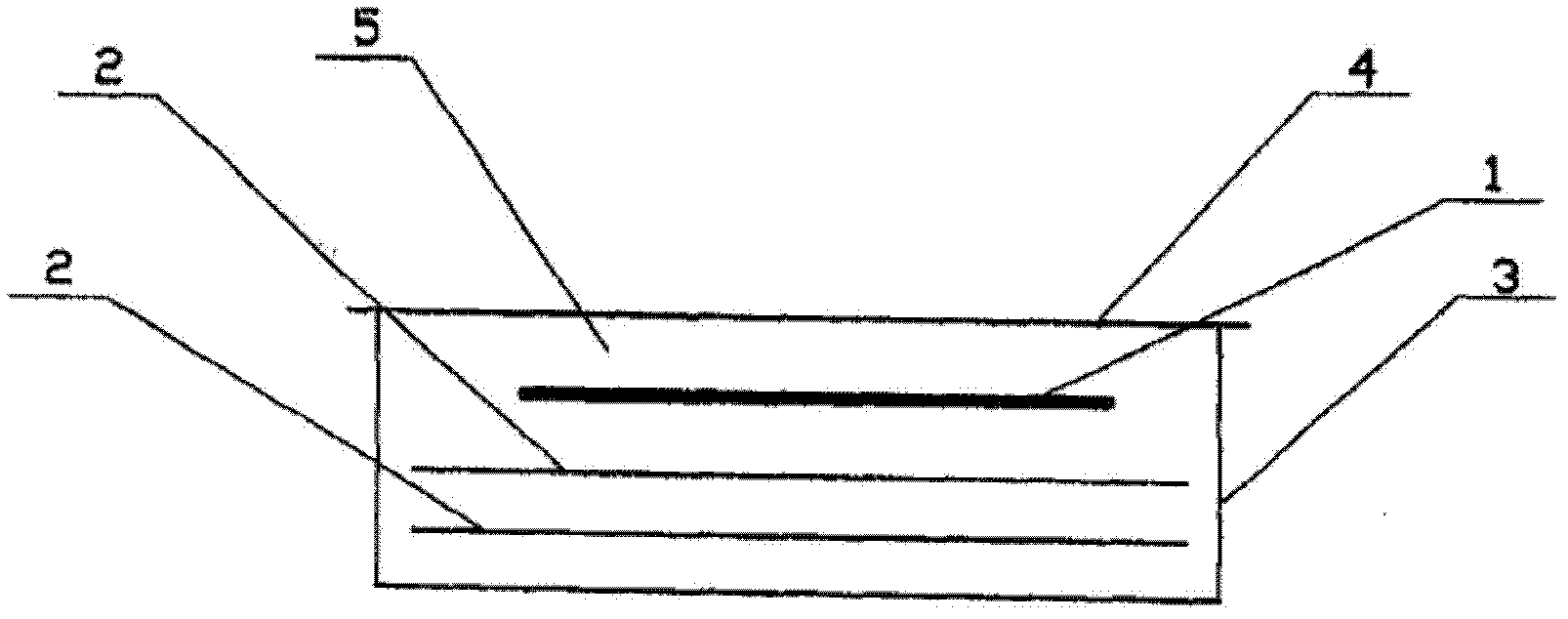

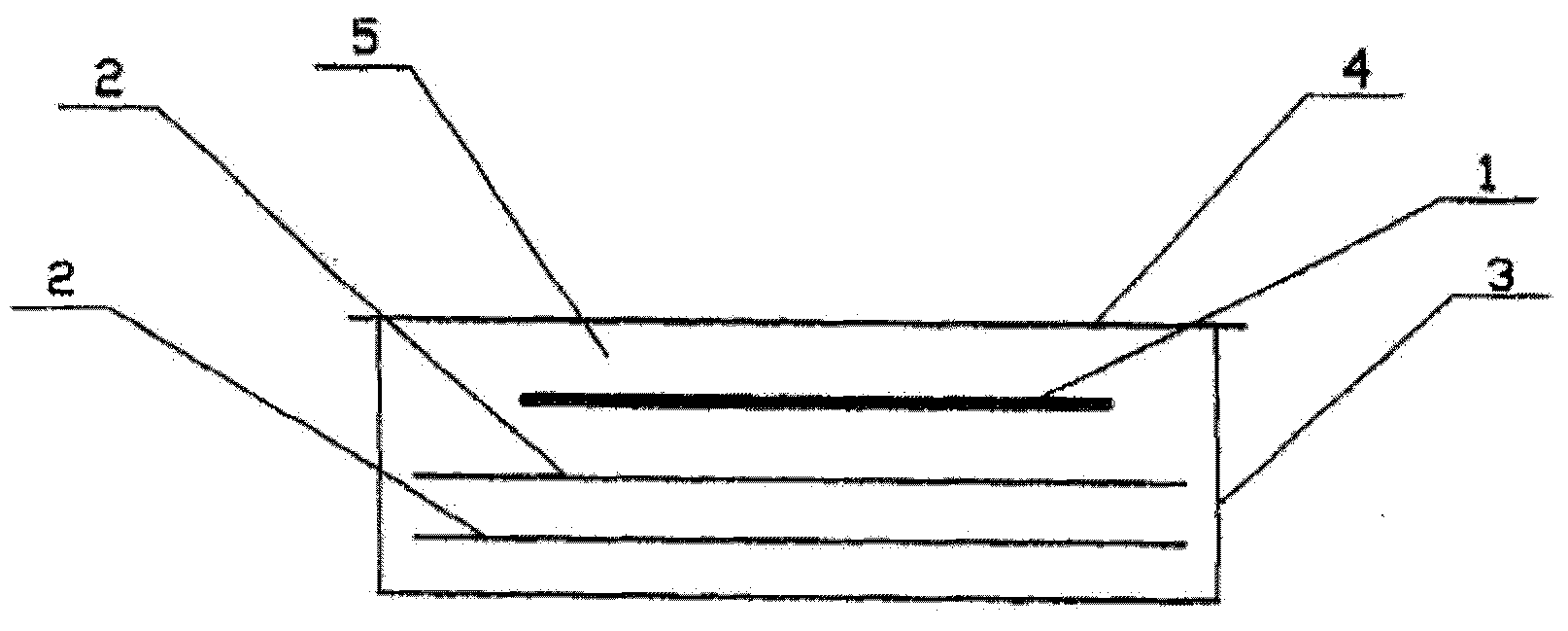

Image

Examples

Embodiment 1

[0032] Include the following steps:

[0033] (1) hot rolling the cold-rolled steel plate to a thickness of 1 ± 0.2mm;

[0034] (2) The surface of the hot-rolled steel plate is coated with a heat-treated protective coating with a thickness of 0.5±0.05mm and containing 1% Nb; when the niobium content is high, the magnetic properties are reduced; when the niobium content is low, the final forming of the material is difficult. If batch production such as vacuum three-beam processing method or electrochemical method is adopted, the cost is high and it is not easy to produce in batches. If niobium is added during alloy smelting, it will have no effect on the magnetic properties due to the effect of grain refinement.

[0035] (3) heat-treating the steel plate coated with heat-treated protective paint at a temperature of 850°C to 900°C;

[0036] (4) Cold rolling to a thickness of 0.05±0.005mm;

[0037] (5) heat treatment at a temperature of 700°C to 750°C;

[0038] (6) cooling to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com