Ceramic capacitor and preparation method of the ceramic capacitor

A technology of ceramic capacitors and buffer materials, which is applied to fixed capacitor casings/packages, components of fixed capacitors, etc., can solve the problems of large impact of ceramic chips, increased production costs, cracked ceramic chips, etc., and achieves excellent shock absorption and buffering capacity. The effect of good weather resistance and excellent insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below through specific embodiments.

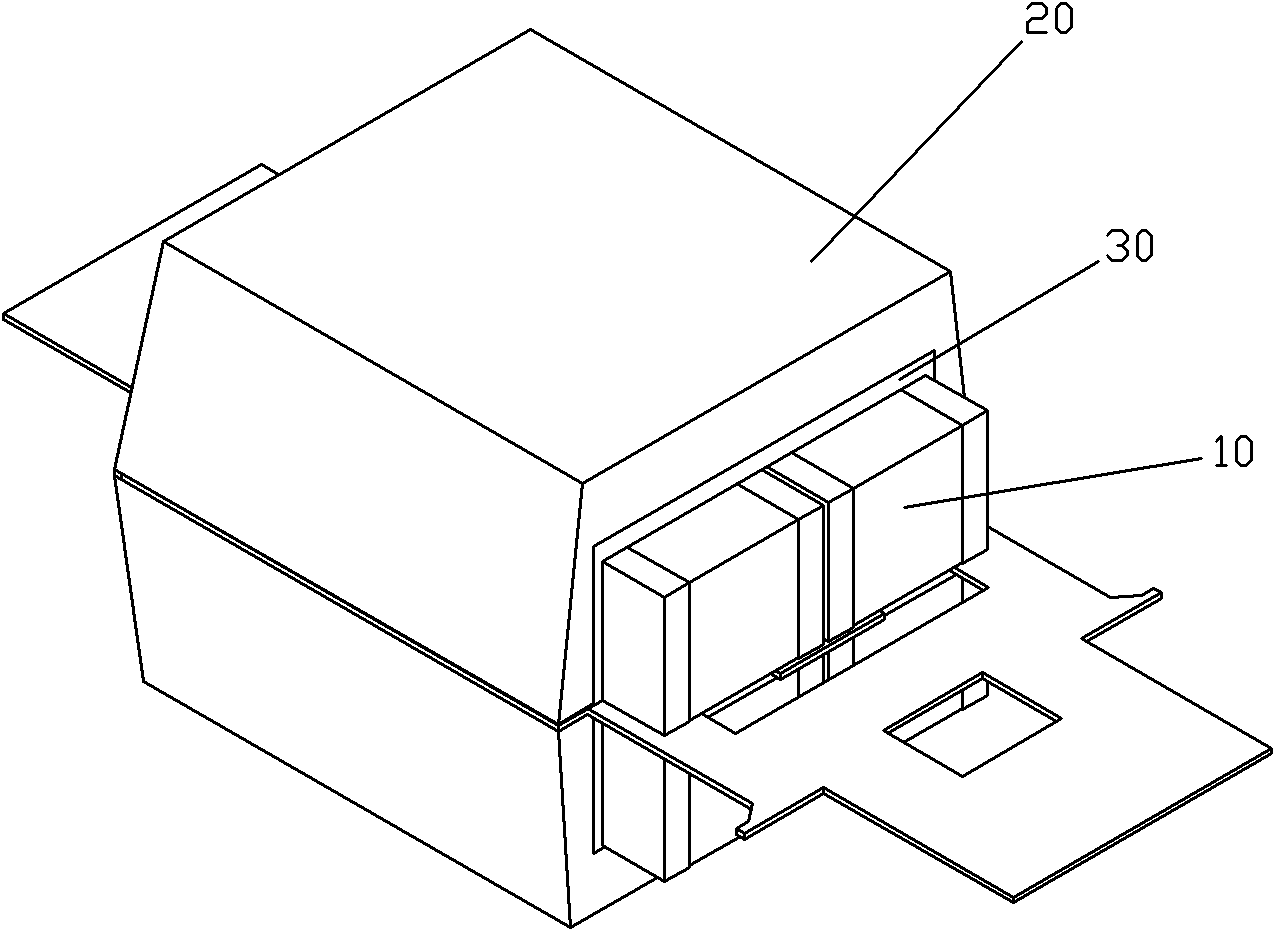

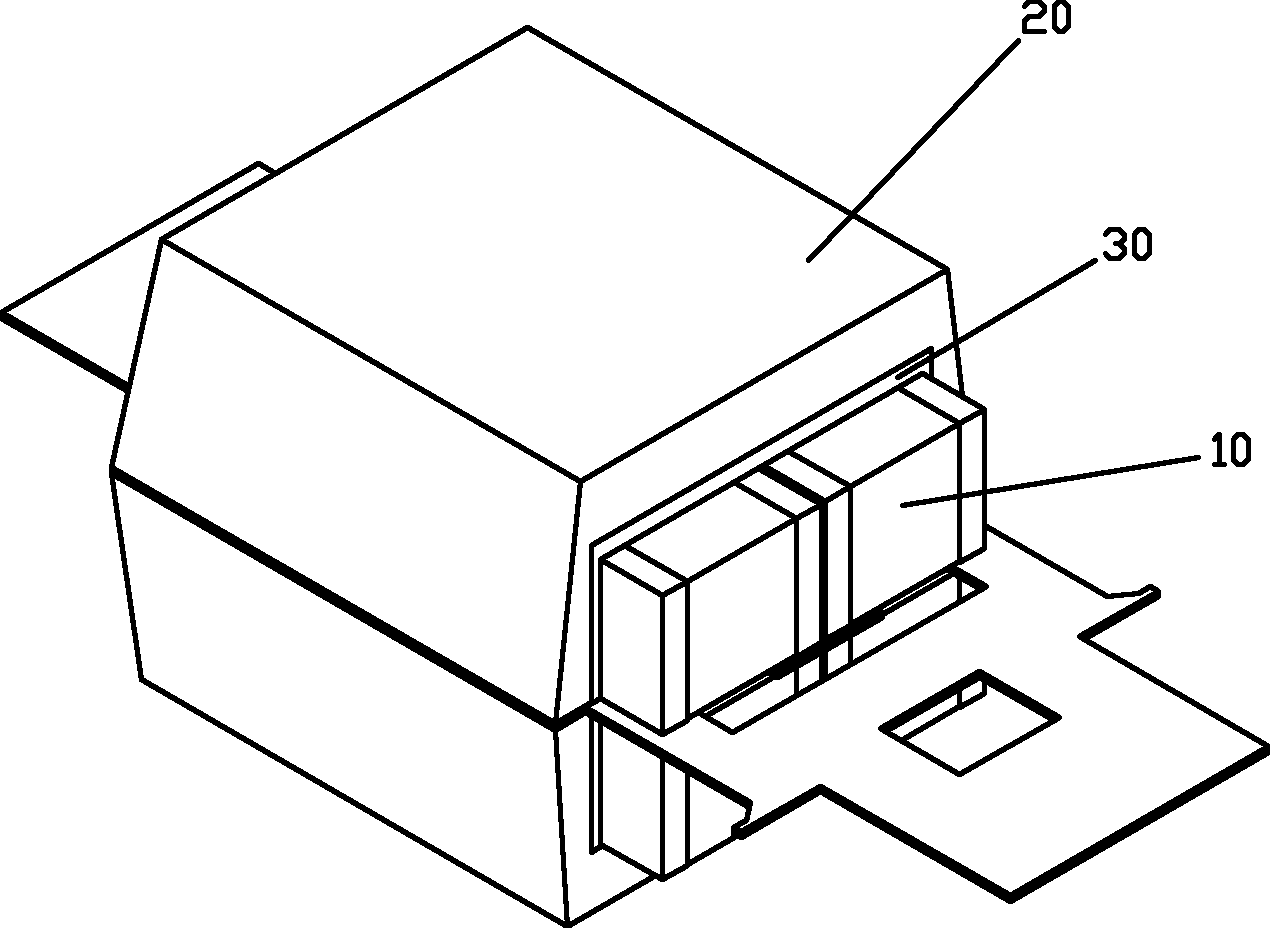

[0016] refer to figure 1 , a ceramic capacitor of the present invention includes a ceramic capacitor body 10 and an epoxy resin encapsulation layer 20 encapsulated outside the ceramic capacitor body 10, and between the ceramic capacitor body 10 and the epoxy resin encapsulation layer 20 There is a layer 30 of cushioning material. The ceramic capacitor body 10 is composed of multi-core ceramic capacitor chips, and the cushioning material layer 30 can be made of silicone, bonding glue or red glue and other cushioning materials.

[0017] When manufacturing a ceramic capacitor of the present invention, firstly, viscous silicone, bonding glue or red glue and other cushioning materials are coated on the outside of the ceramic capacitor body 10, and then epoxy resin is used for molding and encapsulation. encapsulation.

[0018] The above is only a specific embodiment of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com