Carbon-coating and surface film performing co-modification preparation method of anode material of lithium ion secondary battery

A secondary battery and graphite negative electrode technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of deficiencies and inability to comprehensively improve the performance of graphite, achieve low cost, improve the first coulombic efficiency, and increase the amount of lithium intercalation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

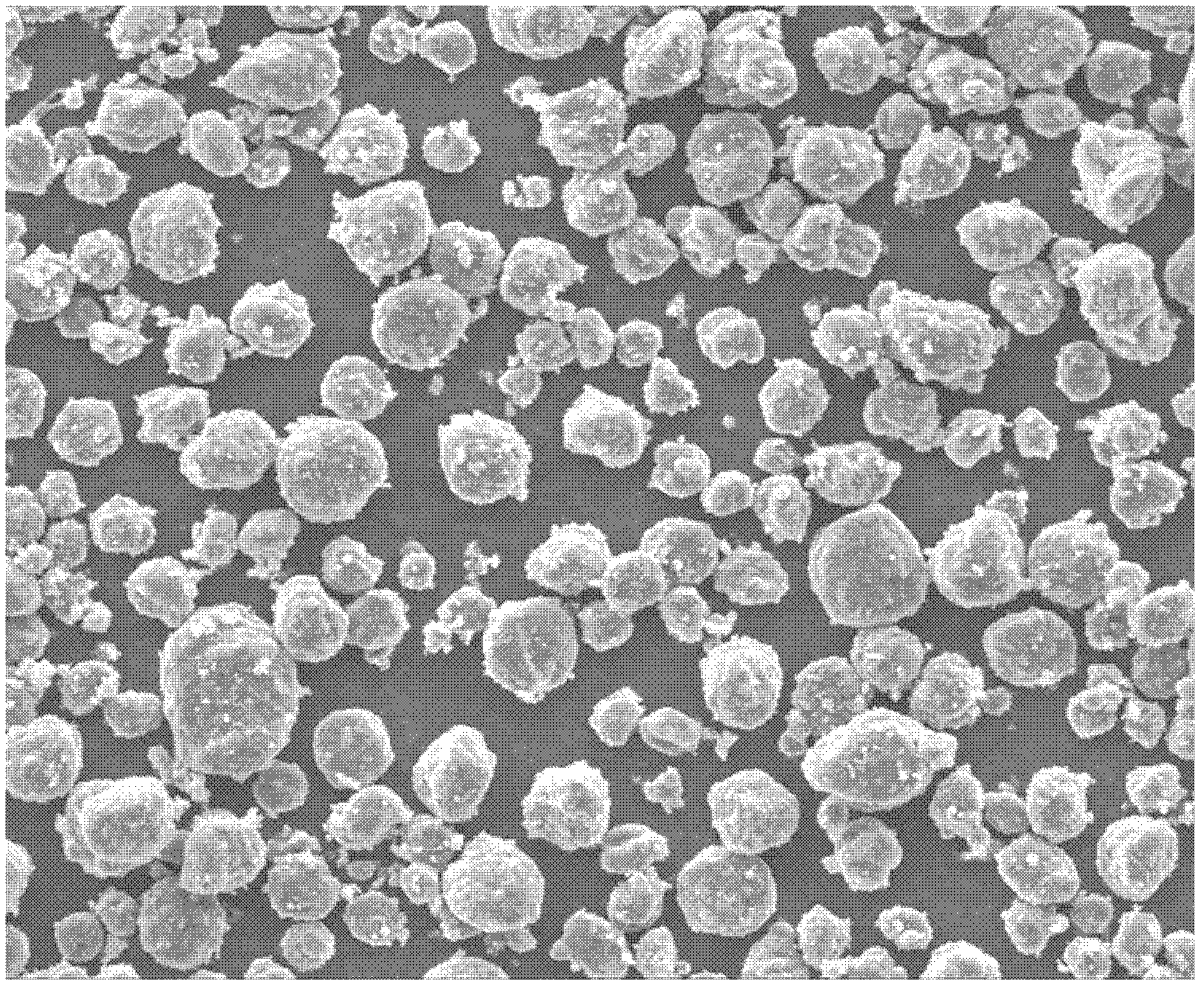

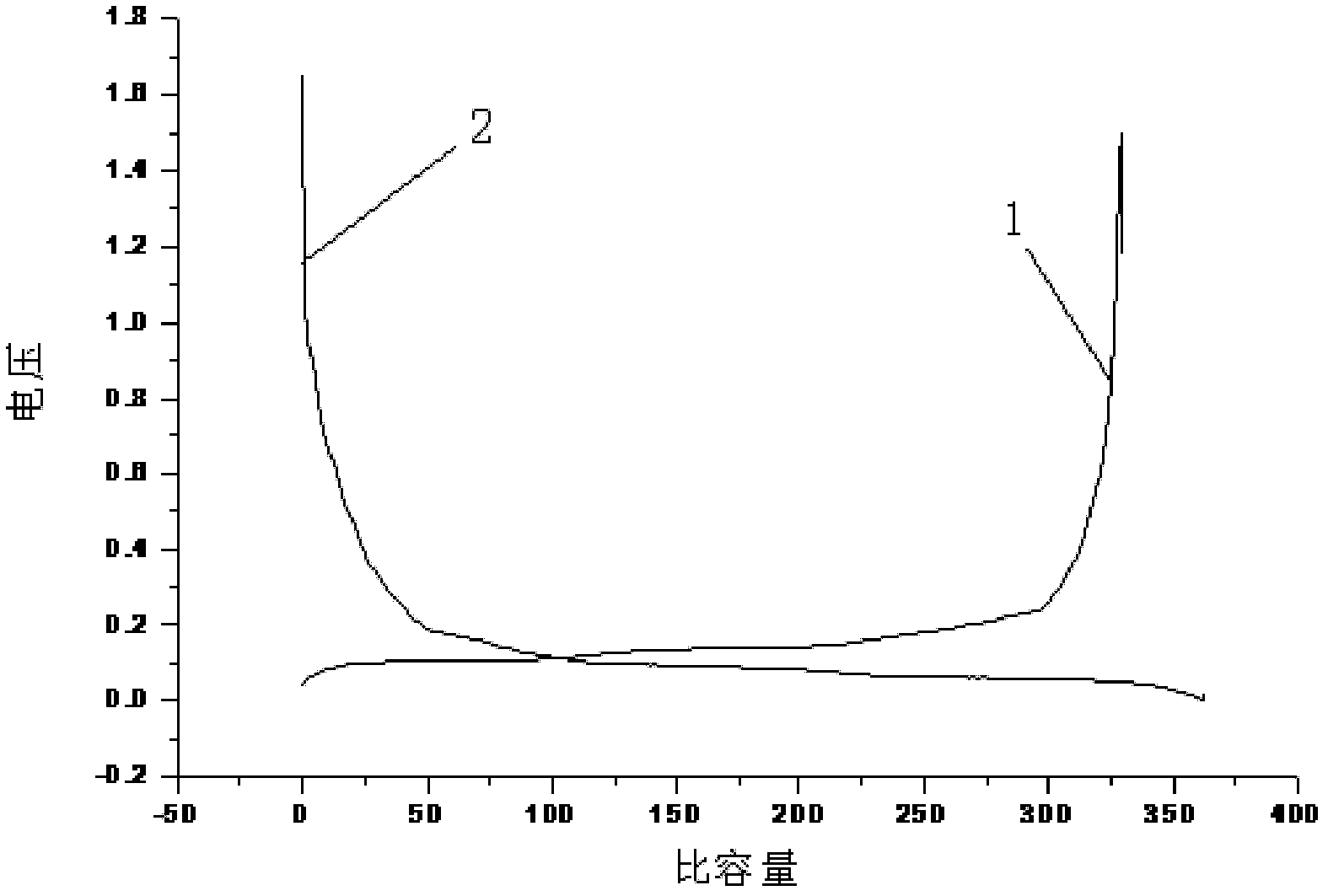

[0019] Get natural graphite and crush it through a crusher, then sieve it with a 325-mesh sieve, collect the part under the sieve for subsequent experiments, weigh stearic acid and graphite in a ratio of 3:100 by stearic acid and graphite mass ratio, Dissolve the weighed stearic acid with alcohol. After the stearic acid is completely dissolved, add the weighed graphite in batches under stirring conditions, and then put the mixture into an ultrasonic oscillator for dispersion treatment. The shaking time 3 hours; after dispersing evenly, put it in an oven to dry, first dry at 90°C for 1 hour, then heat up to 130°C and dry for 3 hours; the dried mixture is crushed and sieved through a 325-mesh sieve. The lower part is subjected to carbonization treatment. The carbonization treatment condition is to first raise the temperature to 380°C for 2 hours under the isolation of air, and then raise the temperature to 800°C for 5 hours. After carbonization, the sample is crushed and pas...

Embodiment 2

[0022] Get natural graphite and crush it through a crusher, then sieve it with a 325-mesh sieve, collect the part under the sieve for subsequent experiments, weigh stearic acid and graphite in a ratio of 6:100 by stearic acid and graphite mass ratio, Dissolve the weighed stearic acid with alcohol. After the stearic acid is completely dissolved, add the weighed graphite in batches under stirring conditions, and then put the mixture into an ultrasonic oscillator for dispersion treatment. The shaking time for 3 hours. Disperse evenly and put it in an oven to dry, firstly dry at 90°C for 1 hour, then heat up to 130°C and dry for 3 hours; the dried mixture is crushed and sieved through 325 mesh, and the under-sieve part is taken for carbonization Treatment, carbonization treatment conditions: first raise the temperature to 380°C for 2 hours under the isolation of air, and then raise the temperature to 900°C for 5 hours. Weigh polydimethylsiloxane and surface carbon-coated graphite...

Embodiment 3

[0025] Get natural graphite and crush it through a crusher, then sieve it with a 325-mesh sieve, collect the part under the sieve for subsequent experiments, weigh stearic acid and graphite in a ratio of 9:100 by stearic acid and graphite mass ratio, Dissolve the weighed stearic acid with alcohol. After the stearic acid is completely dissolved, add the weighed graphite in batches under stirring conditions, and then put the mixture into an ultrasonic oscillator for dispersion treatment. The shaking time for 3 hours. Disperse evenly and put it in an oven to dry, firstly dry at 90°C for 1 hour, then heat up to 130°C and dry for 3 hours; the dried mixture is crushed and sieved through 325 mesh, and the under-sieve part is taken for carbonization Treatment, carbonization treatment conditions: first raise the temperature to 380°C for 2 hours under the isolation of air, and then raise the temperature to 1000°C for 5 hours. Weigh polydimethylsiloxane and surface carbon-coated gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com