Fuel cell

A fuel cell and membrane electrode technology, which is applied to fuel cells, fuel cell parts, solid electrolyte fuel cells, etc., can solve the problems of complex process, long cycle, aging of encapsulant, etc., and achieve simple production process and short production cycle. , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

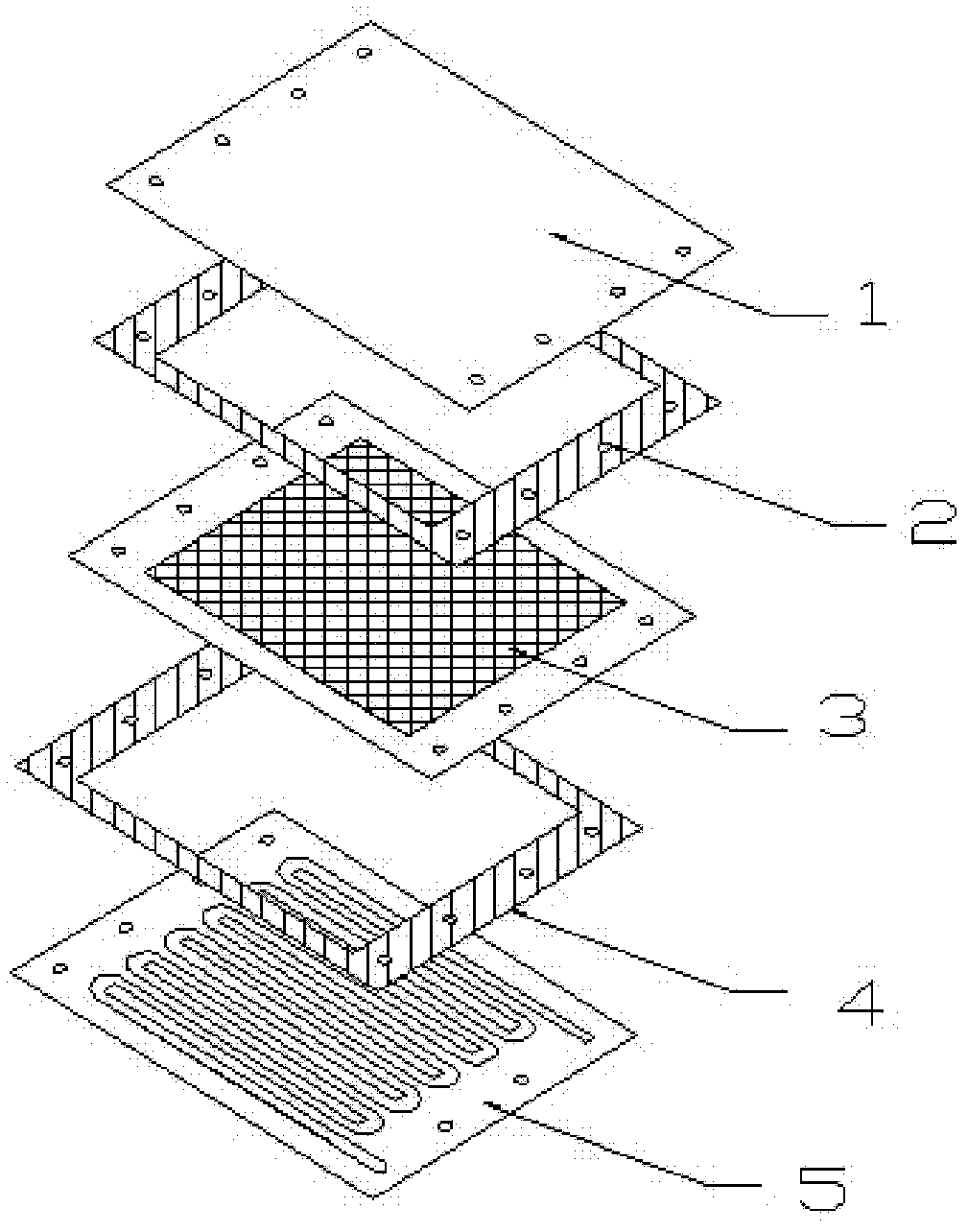

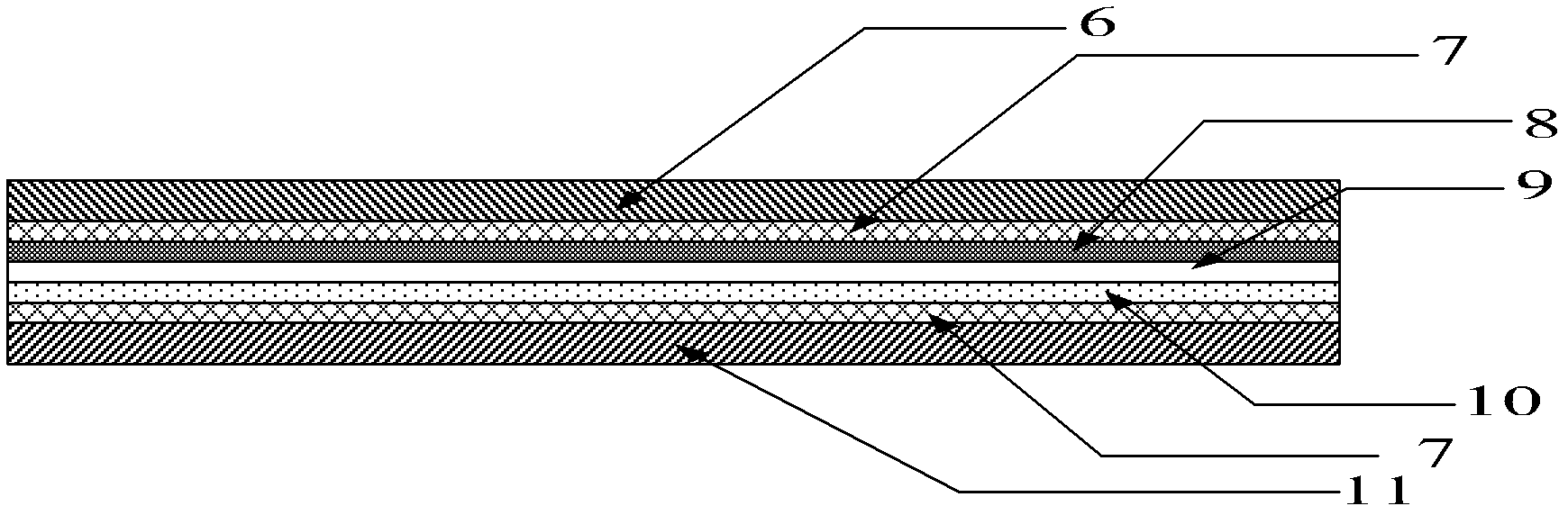

[0031] image 3 The schematic diagram of the structure of the fuel cell prepared in this example, the specific preparation process is as follows:

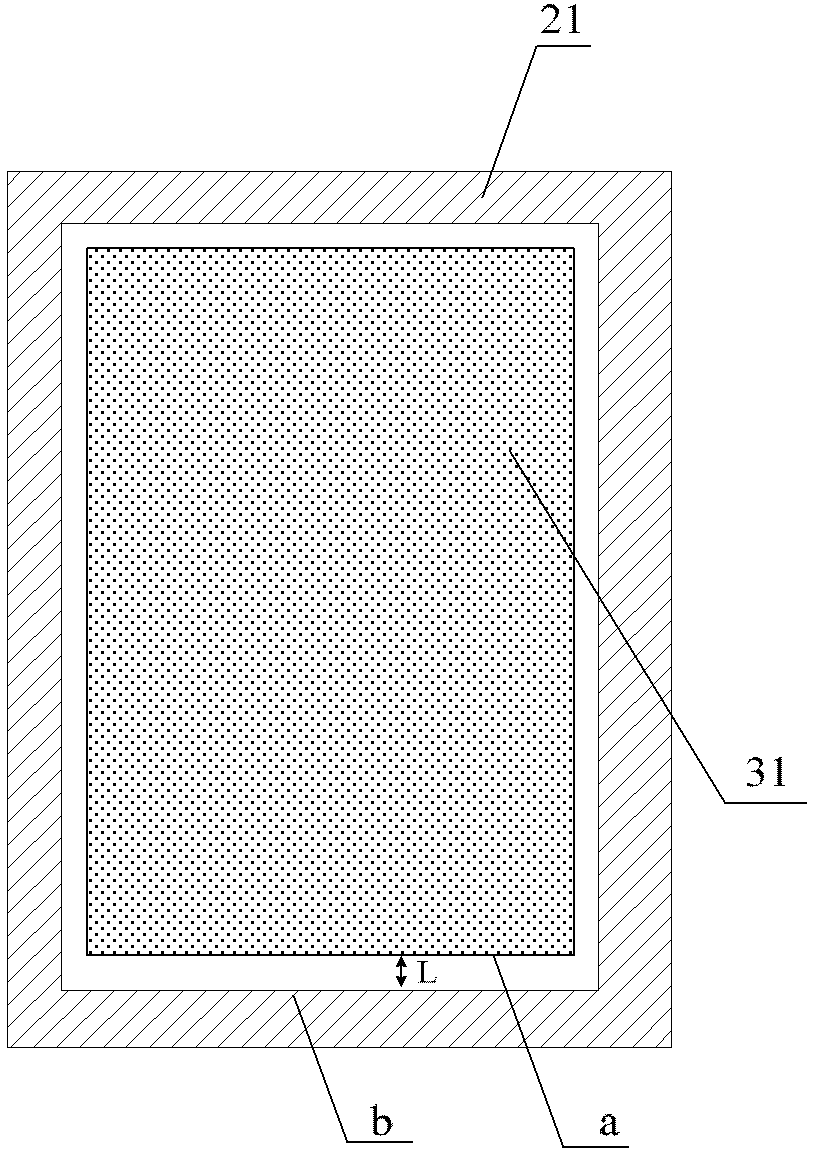

[0032] Fix the stainless steel sealing sheet 7 on the contact membrane electrode side of the anode plate 6 through silica gel, place the silica gel sheet 8 on the stainless steel sealing sheet 7 side of the anode plate 6, and fix the other stainless steel sealing sheet 7 on the cathode plate through silica gel 11 on the contact membrane electrode side, the graphite paper sealing sheet 10 is placed on the stainless steel sealing sheet 7 side of the cathode electrode plate 11, the membrane electrode 9 is placed between the cathode electrode plate 11 and the anode electrode plate 6 with the sealing sheet, through The screw is tightly pressed to achieve a sealing effect. The sealing structure provided in this embodiment includes: an anode plate 6 , a stainless steel sealing sheet 7 , a silica gel sheet 8 , a membrane electrode 9 , a g...

Embodiment 2

[0034] Figure 4 The schematic diagram of the structure of the fuel cell prepared in this example, the specific preparation process is as follows:

[0035] The fluorosilicone sealing sheet 13 is placed on the anode plate 12 side, the graphite paper sealing sheet 15 is placed on the cathode electrode plate 16 side, and the membrane electrode 14 is placed in the middle of the fluorosilicone sealing sheet 13 and the graphite paper sealing sheet 15, The sealing effect is achieved by pressing the screw tightly. A plurality of membrane electrodes and plates are sealed and connected in series to form a sealed stack. The sealing structure provided in this embodiment includes: an anode plate 12 , a fluorosilicone sealing sheet 13 , a membrane electrode 14 , a graphite paper sealing sheet 15 and a cathode plate 16 which are stacked in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com