Powder milling system with double-clip butterfly valve

A butterfly valve and clip-type technology, which is applied in the field of milling production system with pneumatic clip-on butterfly valve, can solve the problems of easy generation of coarse particles, achieve the effect of reducing product raw material loss, reducing production cost, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

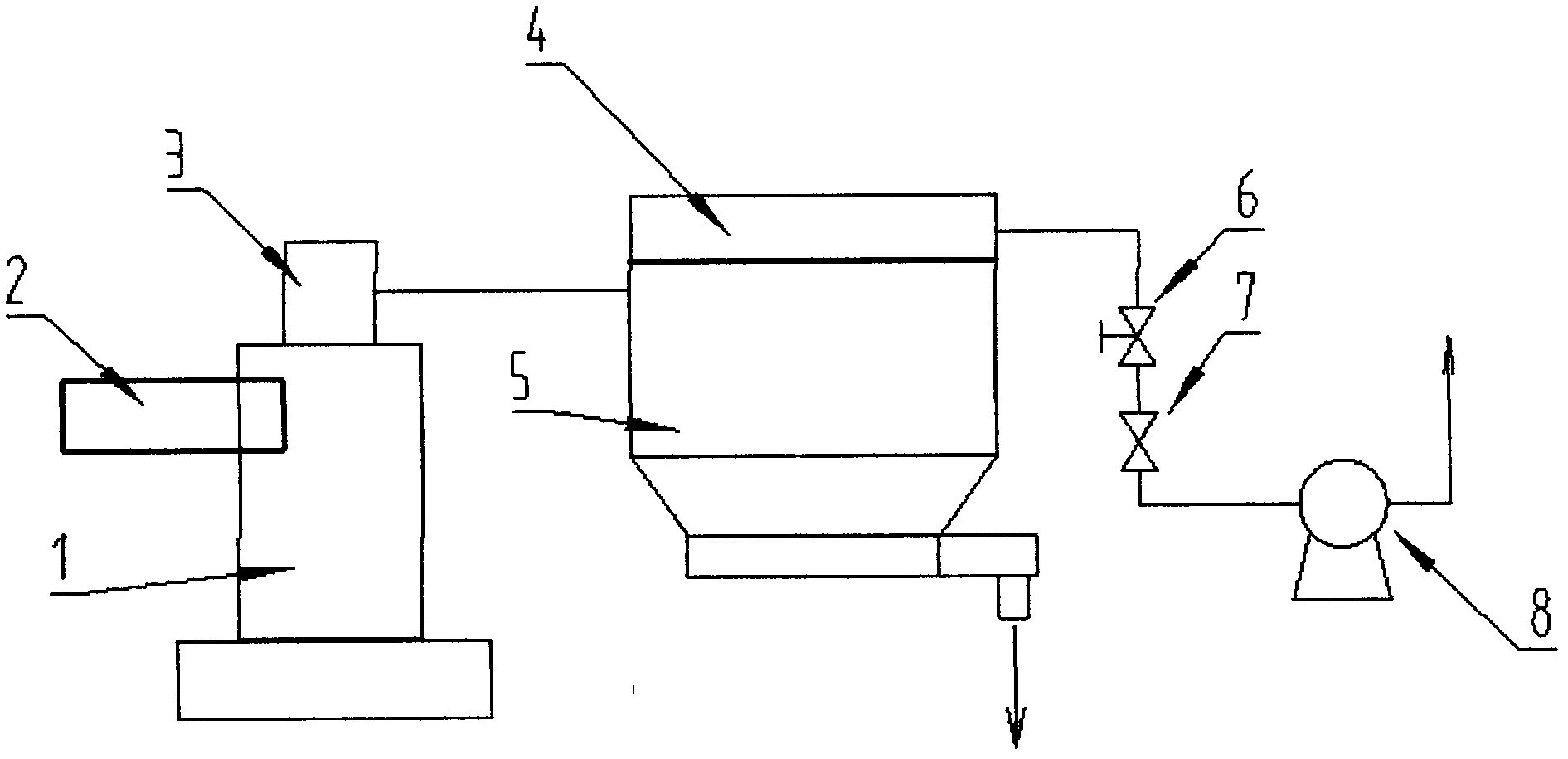

[0017] Such as figure 1 As shown, a milling production system with a clip-on butterfly valve of the present invention is composed of the following equipment: comprising a mill 1, a feeder 2, a classifier 3, a powder collector 4, a supporting pulse cleaning device 5, Pneumatic wafer butterfly valve 6, air valve 7, fan 8 are characterized in that: pneumatic wafer butterfly valve 6 is installed in front of the inlet of air valve 7 and is interlocked with classifier 3.

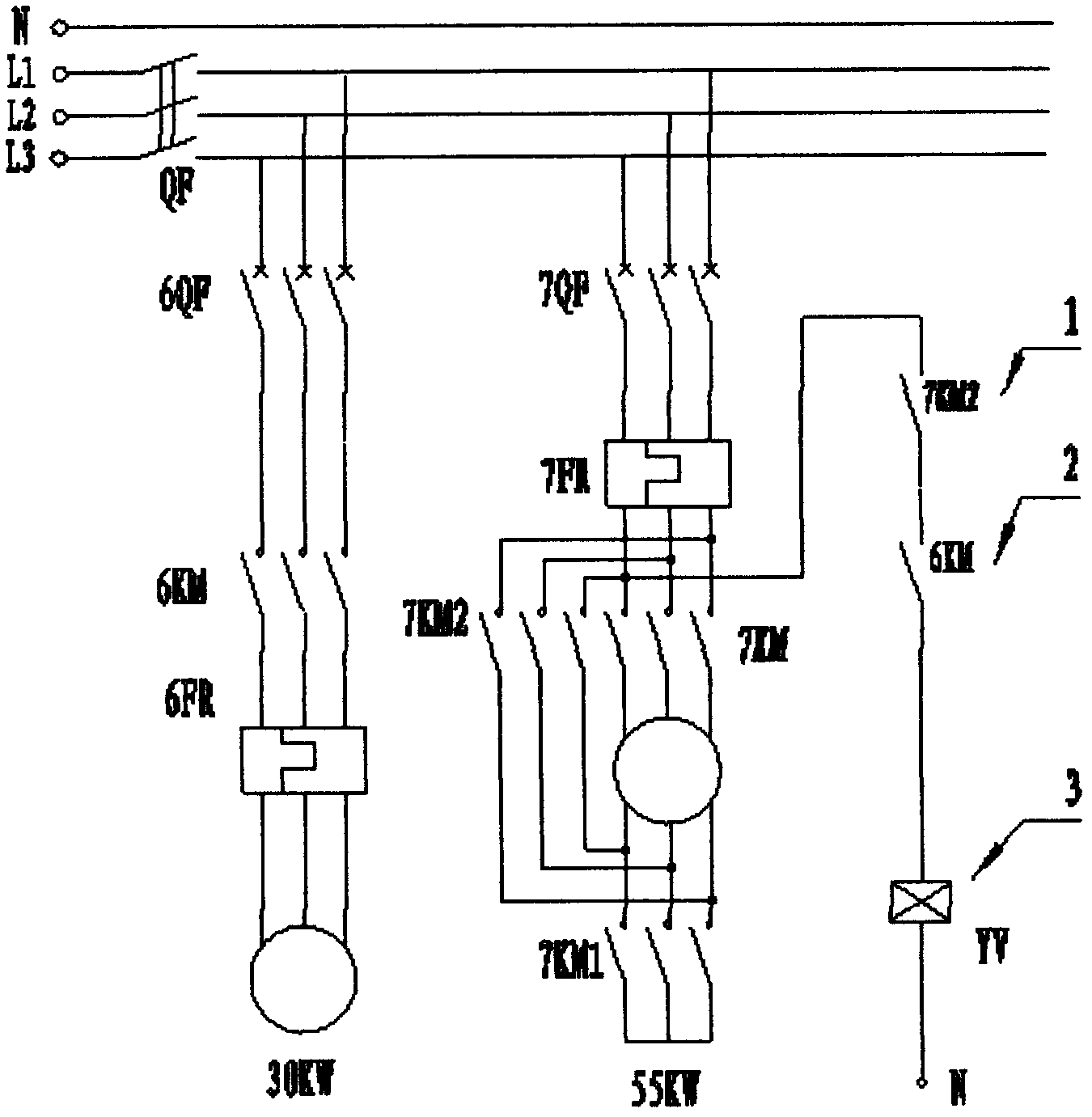

[0018] The method of interlocking the pneumatic wafer butterfly valve with the classifier: when the classifier is running normally, the fan runs and the AC contactor 7KM2 pulls in, figure 2 The normally open contact 1--7KM2 is closed, the classifier AC contactor 6KM is closed, figure 2 The normally open contact 2--6KM is closed, figure 2 The solenoid valve coil 3 of the pneumatic butte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap