High-precision automatic paint sprayer and paint spraying method

An automatic paint spraying machine, high-precision technology, applied in the direction of spraying devices, etc., can solve the problems of complex motor control, large error in feeding and rotary position of the turntable, flying oil, etc., to achieve a high degree of automation, reduce working time, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

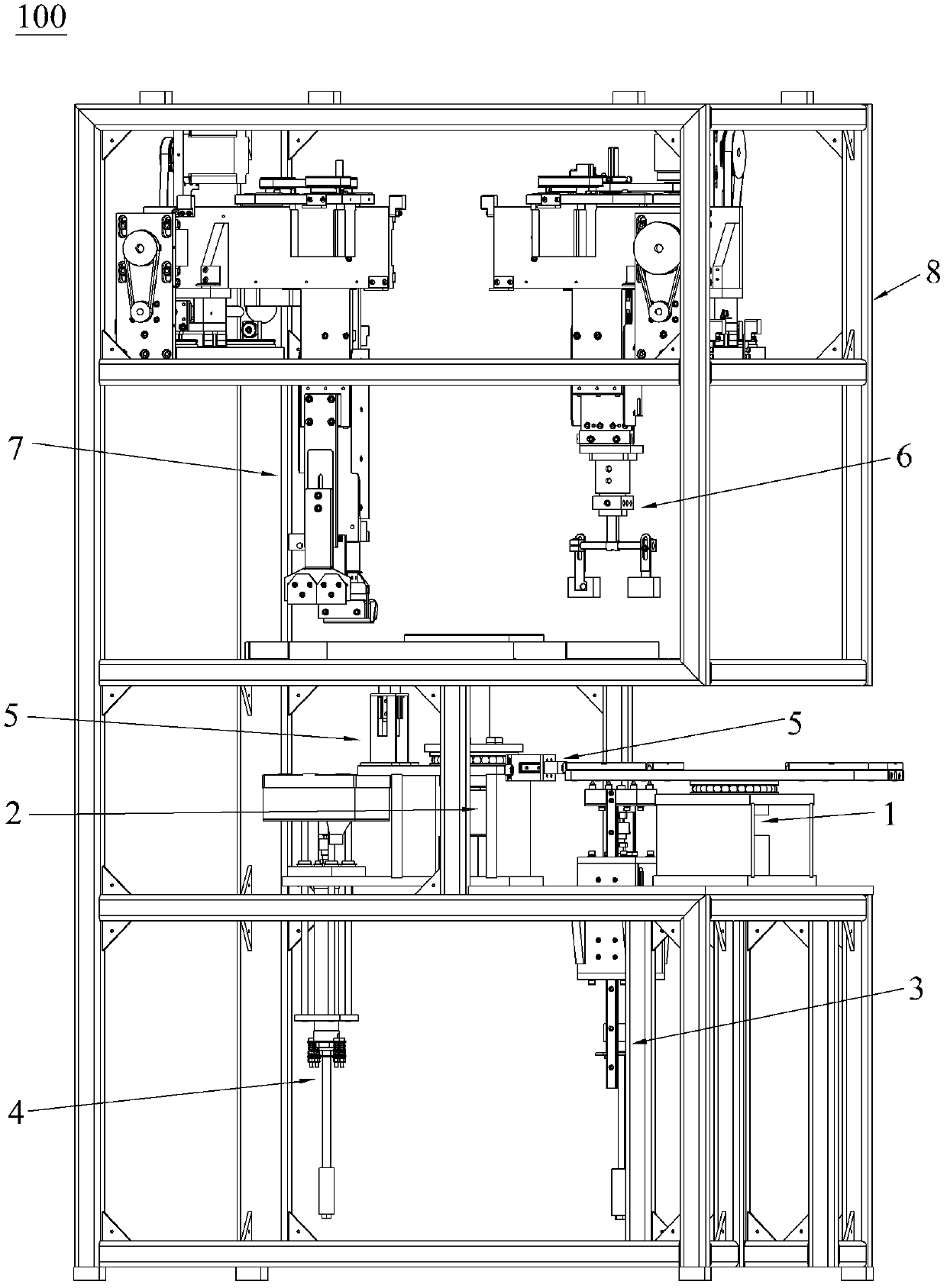

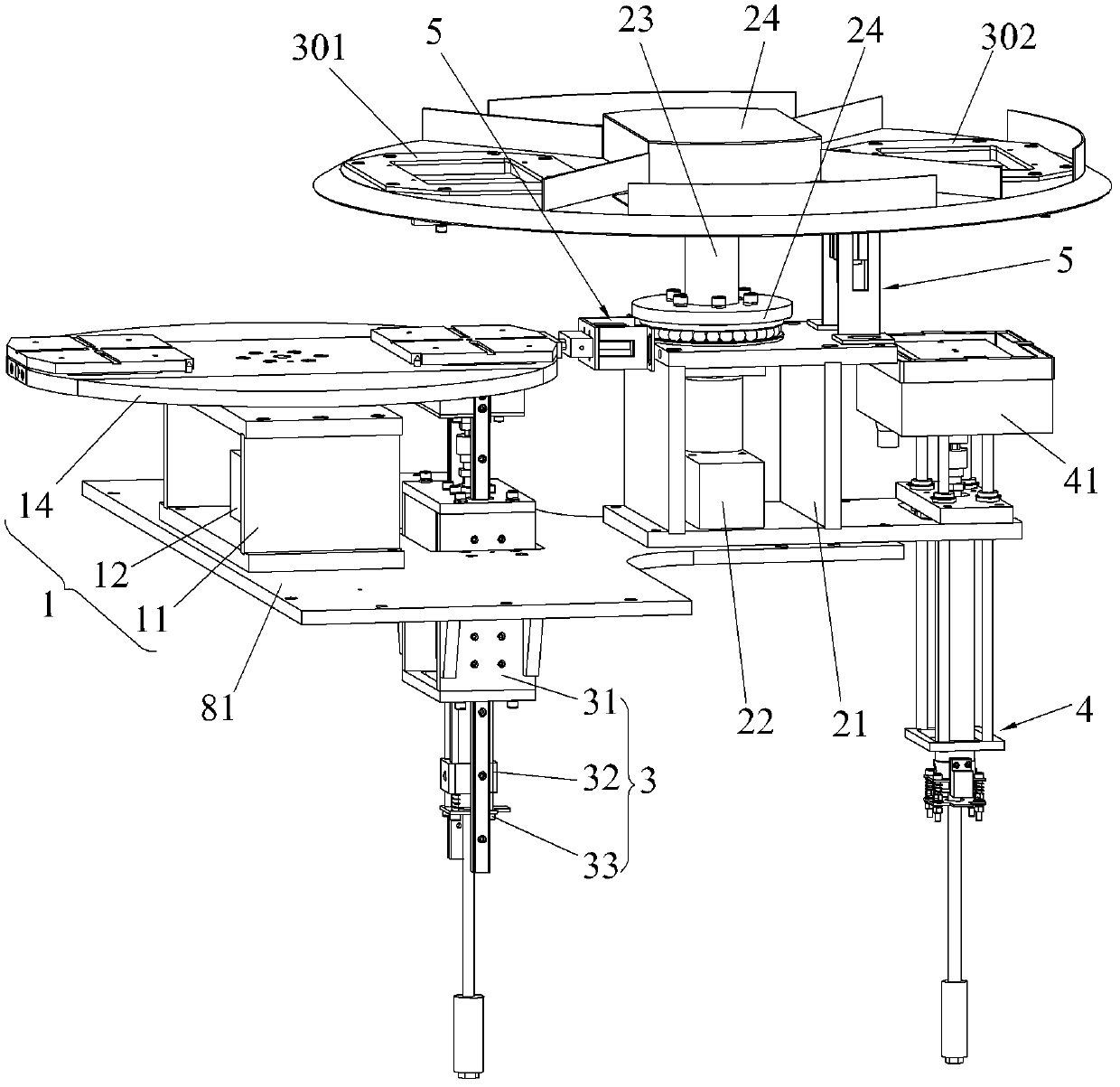

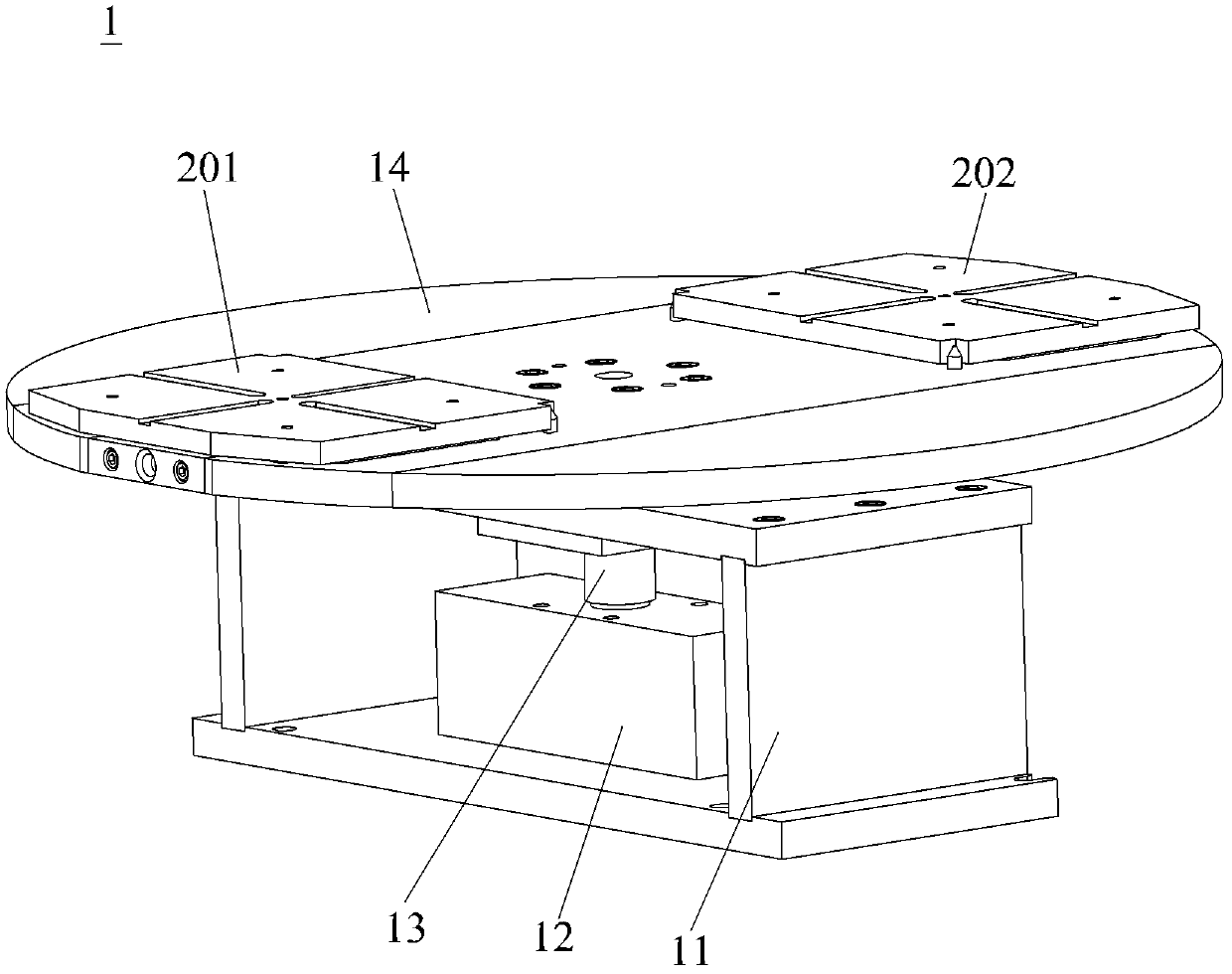

[0028] Such as figure 1 and figure 2As shown, the high-precision automatic paint spraying machine 100 of the present invention is suitable for spraying workpieces (not shown in the figure), including a rotary feeding device 1, a rotary mold changing device 2, a front mold clamping device 3, a rear mold clamping device 4, two positioning Device 5, painting device 6, cleaning device 7, control system (not shown in the figure) and frame 8; the frame 8 is horizontally provided with a substrate 81, the rotary feeding device 1, rotary mold changing device 2, front closing Both the mold device 3 and the rear mold clamping device 4 are installed on the base plate 81 . The base plate 81 can fix the rotary feeding device 1 , the rotary mold changing device 2 , the front clamping device 3 and the rear clamping device 4 on the same reference, which can greatly reduce position errors and ensure accurate mold clamping.

[0029] see again figure 1 and figure 2 , the two ends of the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com