Production method for bent round wood bars

A production method and round log technology, applied in the manufacture of tools, wood processing appliances, etc., can solve the problems of unsatisfactory, furniture style restrictions, etc., and achieve the effects of increasing strength, saving wood, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

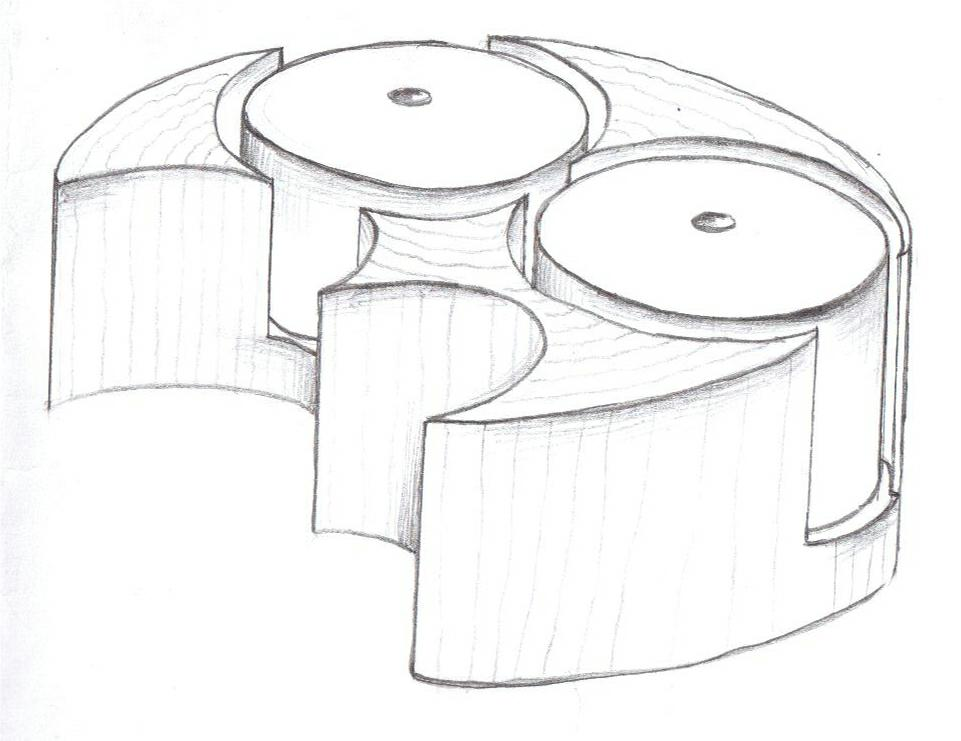

[0019] First, cut the logs into 5-10 cm round wood blocks, and dry them according to conventional methods, such as: drying with microwave equipment, and then directly drill and saw them into small round wood blocks with a through hole in the center with a circular saw milling cutter. When there are scabs in the log, avoid the scabs directly and perform drill sawing. Because the diameter of the small round wood block that is generally drilled and sawed is not large, so it is easier to avoid scabs, without the need to discard more wood, so that the method can effectively save wood.

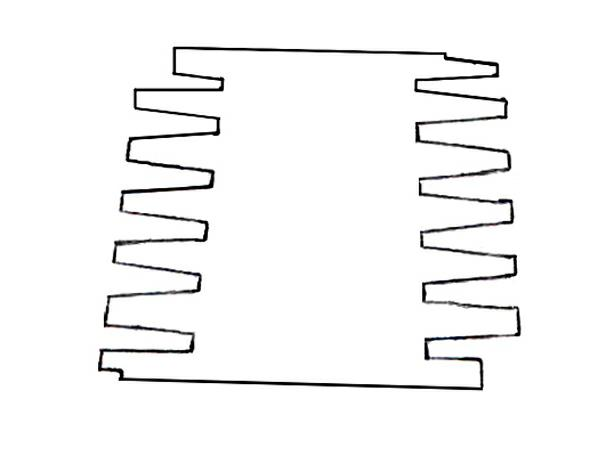

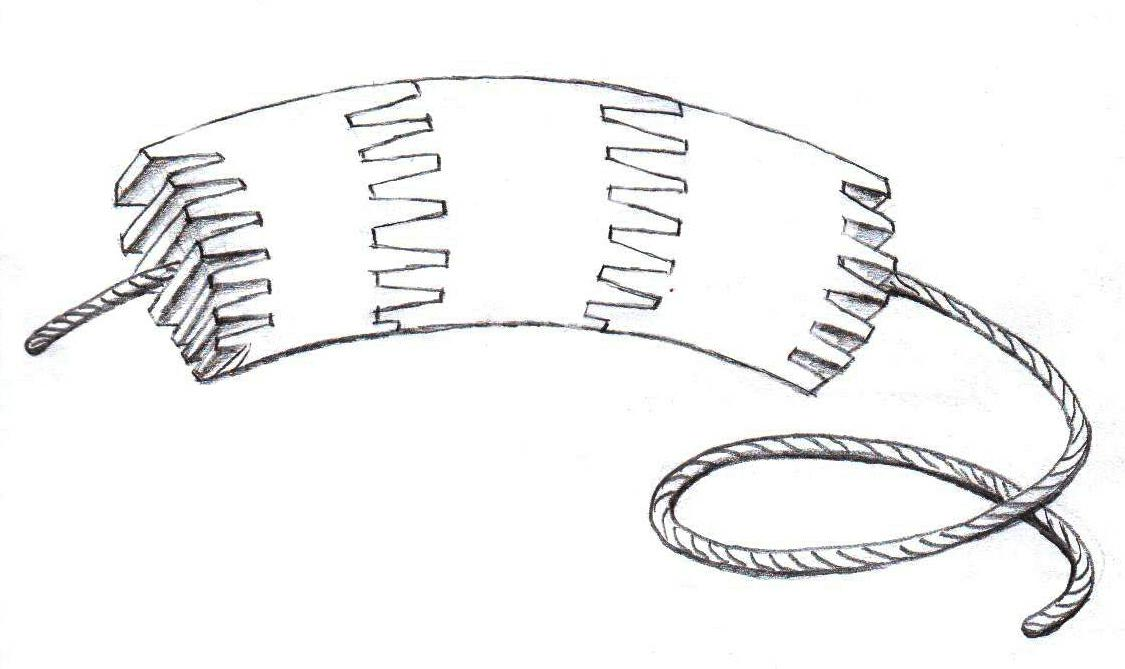

[0020] Slope the small round wooden blocks obtained above according to the required angle, mainly according to the degree of bending to determine the angle of inclination, and then directly process it with a saw blade. After the slope treatment, use the existing comb machine to mill the two ends of the small log into the shape of the row of teeth. Multiple small logs can be processed at the same tim...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap