Method for molding spiral equal-wall-thickness hollow screw pump stator rubber bushing

A molding method and hollow screw technology, applied in the field of rubber processing, can solve the problems of screw pump stator deformation, inability to withstand high pressure, bursting, etc., and achieve the effect of improving process operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

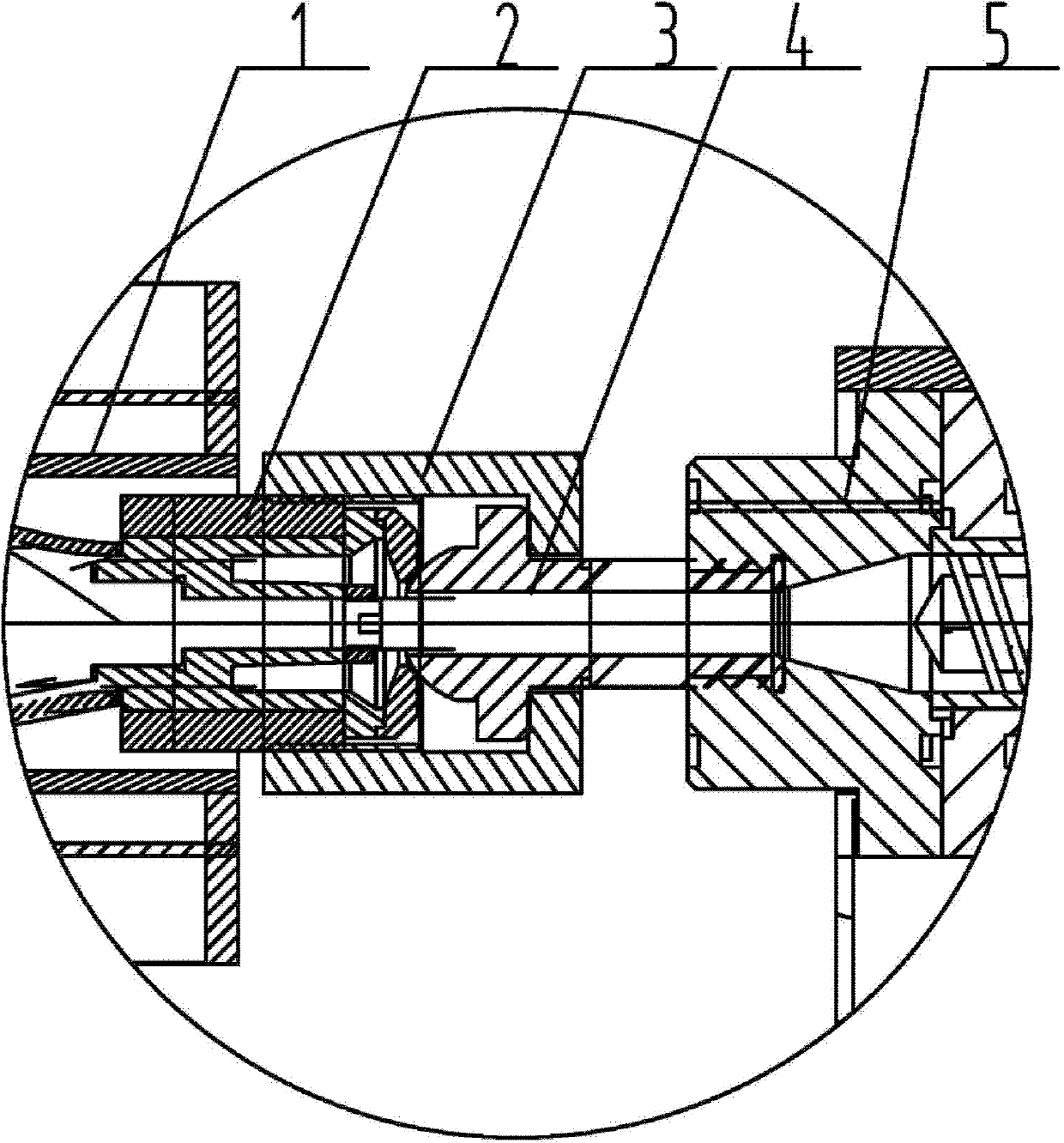

[0017] The molding device used in this embodiment (see figure 1 ) The main structure includes a pulling device 3, a screw pump stator 2 that is internally threaded with the pulling device 3, an extruder nozzle 4 that is directly pressed with the pulling device 3, and the nozzle 4 is reversely threaded to the cold feed extrusion In the machine 5, wherein the pulling device 3 is installed in the heating device 1; molding is carried out according to the following steps:

[0018] (1) First, install the screw pump stator, the mandrel and the runner device on the molding device. The center of the runner and the mandrel is positioned with a 45-degree conical surface, and the axial direction is the axis of the front and rear screw pump stator end faces. Position to the distance to ensure that the end face of the inner flow channel device is the same distance from the end face of the screw pump stator. The stator shell of the screw pump is equidistantly installed with more than 5 rows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com