Device for preparing nano laminated composite material with adjustable layers

A composite material and nano-lamination technology, which is applied in the field of advanced material processing, can solve the problems affecting the molding quality of laminated composite materials, the difficulty of processing laminated composite generators, and the complicated and inflexible operation, so as to achieve the reduction of pressure loss and the design The manufacturing process is simple and the runners have good symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

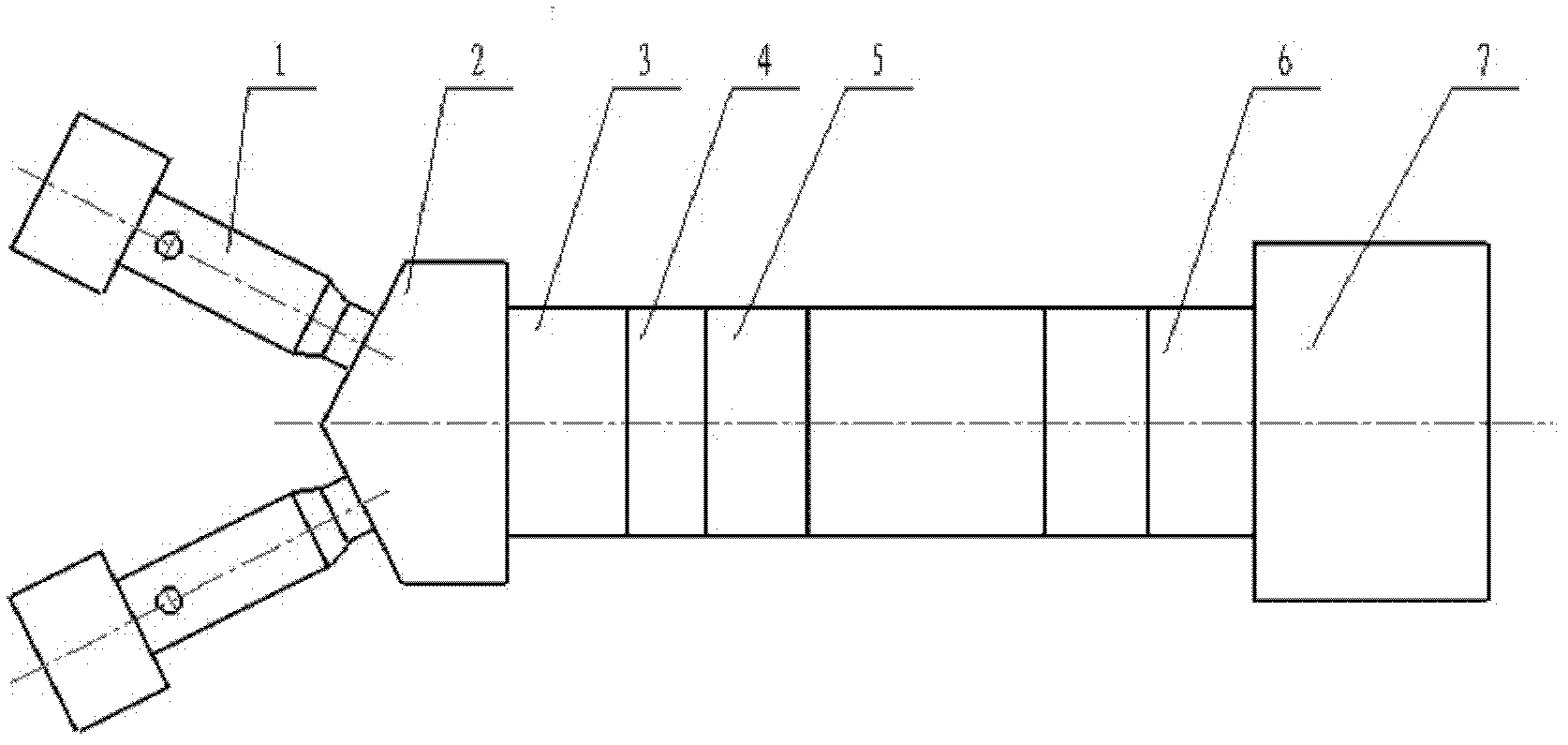

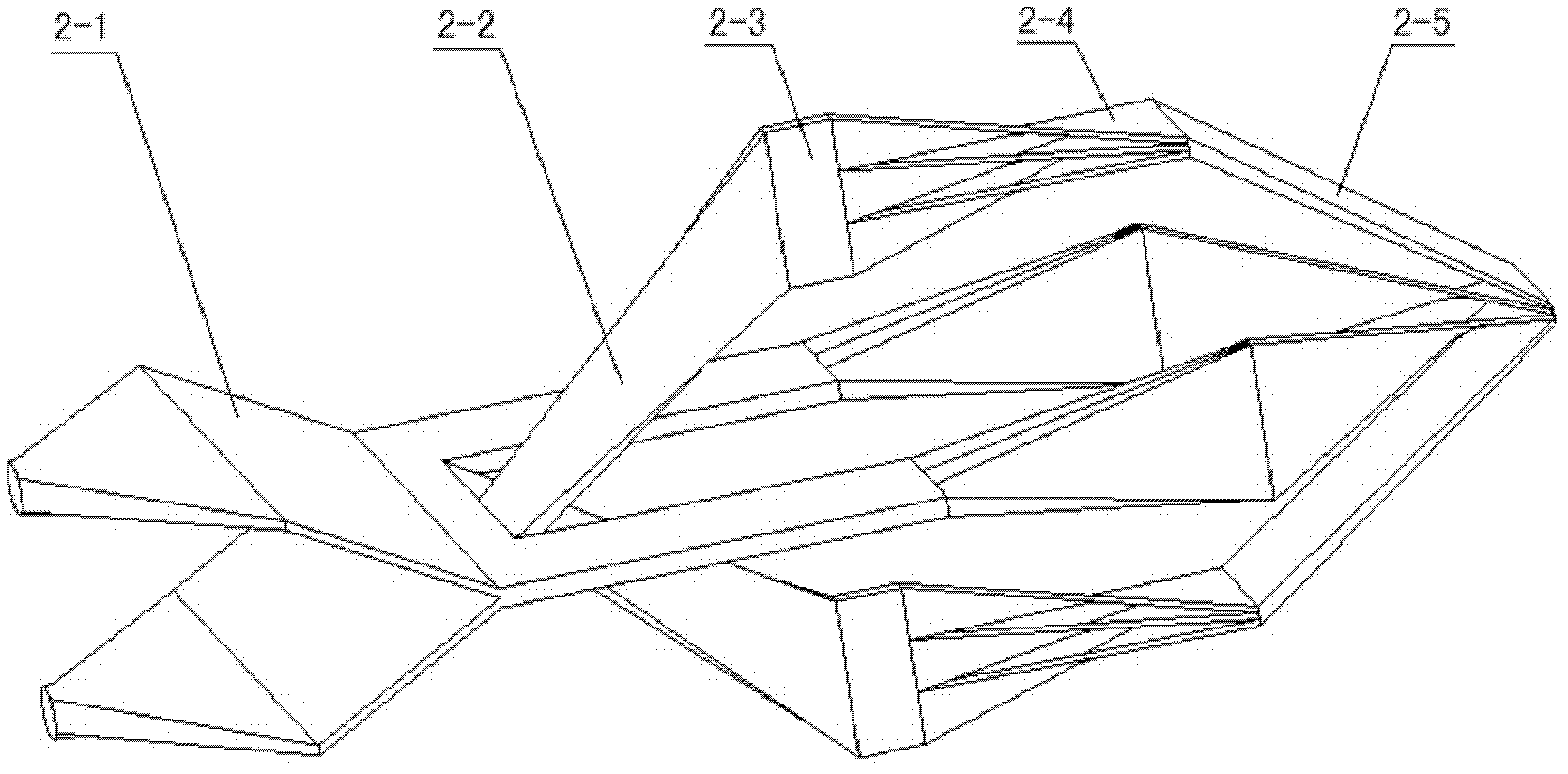

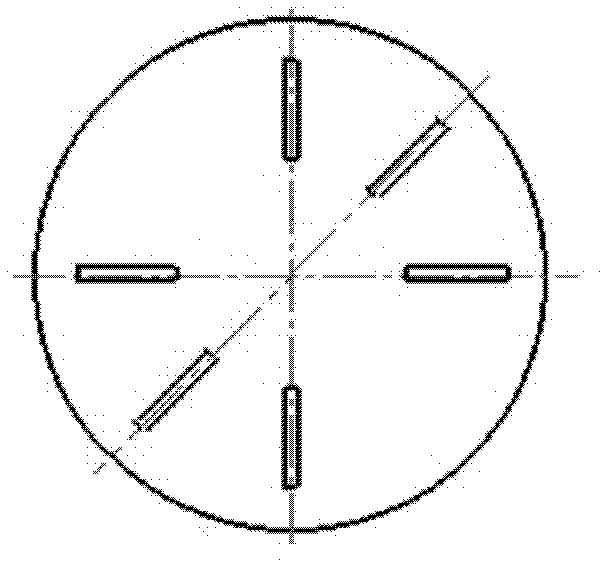

Embodiment 1

[0015] This embodiment discloses a device for preparing a nano-laminated composite material with an adjustable number of layers. The overall shape is as attached figure 1 As shown, there are two or more extruders plasticizing feeder 1, manifold 2, diverter 3, die 4, composite stacker 5, back port die 6 and forming device 7, which are front and back Connect in series. The confluencer 2 converges the n kinds of polymer melts 2-1 from the n sets of plasticizing feeder 1 into n layers of equal-thick polymer melts, and then the melts pass through the splitter 3, where the melts are melted It is divided into 4 equal parts along the width direction. The two melts on the outer side flow along the horizontal flow channel, and the two melts on the inner side rotate 90 degrees when flowing forward. These two groups of melts are symmetrical. Flow, they flow into the corresponding die inlet after exiting the splitter, image 3 with Figure 4 These are the states when the die is at the initi...

Embodiment 2

[0019] This embodiment discloses another example of a nano-laminated composite material preparation device with an adjustable number of layers, as shown in the attached Figure 5 As shown, it is composed of two or more injection molding machines' plasticizing feeder 1, manifold 2, splitter 3, die 4, composite stacker 5, back port die 6, nozzle 8 and mold 9 in series in sequence . The injection nozzle 8 and the mold 9 constitute a molding device, and the nozzle 8 is connected with the mold 9 during injection molding. The melt passes through the combiner 2, the splitter 3, the die 4, and the composite stacker 5, and finally comes out of the back port die outlet and has been superimposed to form 4n×m k Layer (the die is in the initial position) or 2n×m k The composite melt is injected into the cavity of the mold 9 through the nozzle 8 and is cooled and shaped to obtain a polymer laminated composite injection molded product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com